Fine positioning automatic clamping and unloading device on the belt

An automatic clamping and unloading device technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve problems such as low work efficiency, inaccurate positioning, and difficulty in realizing automatic production, so as to improve work efficiency , high market competitiveness, guaranteed stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

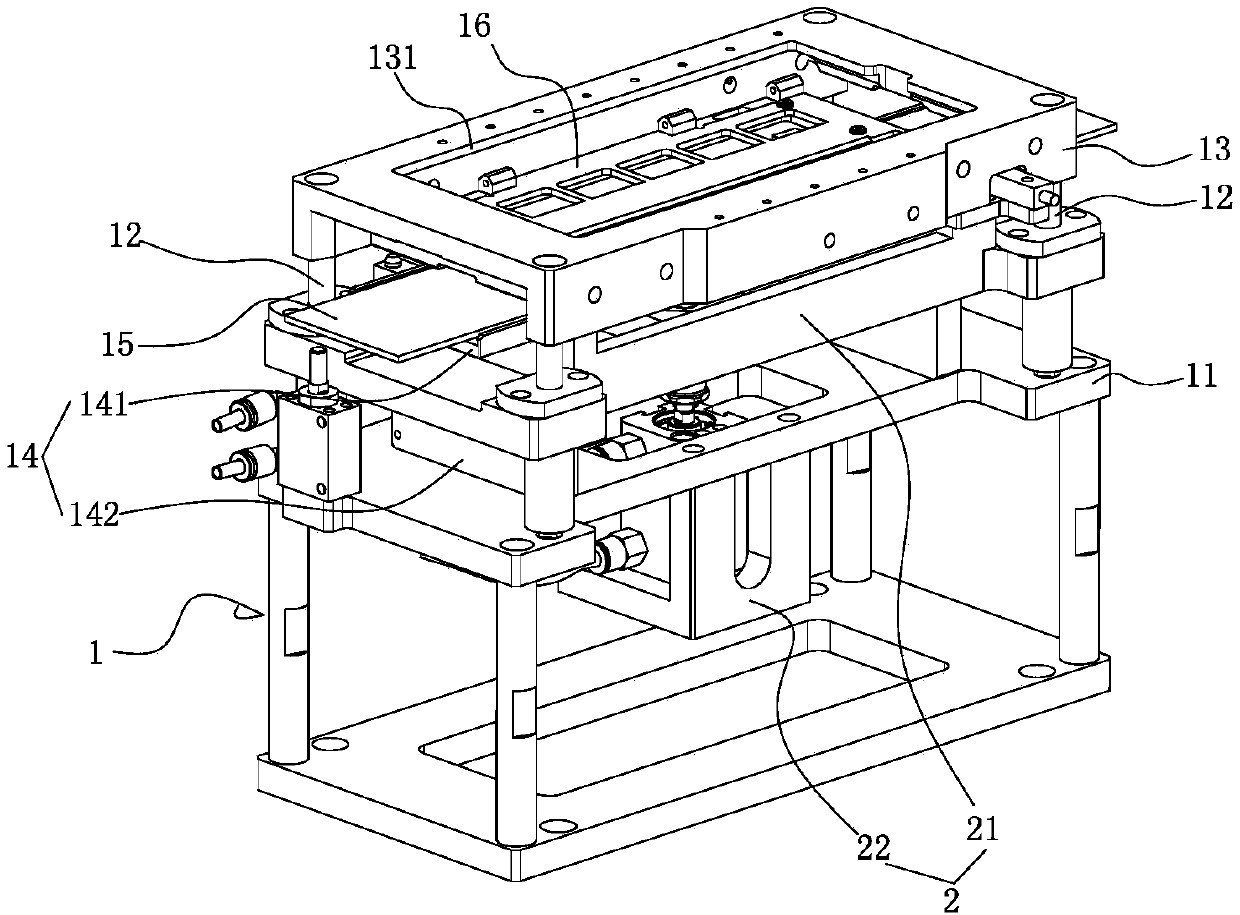

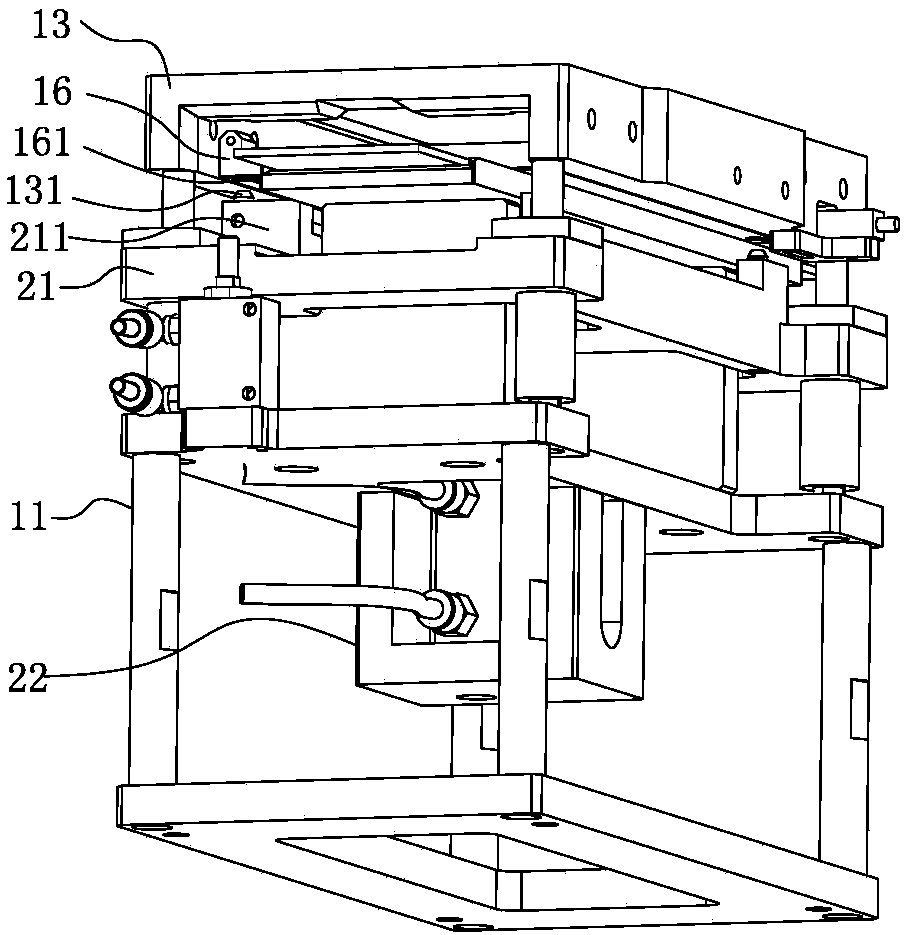

[0020] See Figure 1-5 As shown, it is a precise positioning automatic clamping and unloading device on the belt, which includes: a frame 1 and a lifting mechanism 2 installed on the frame 1 .

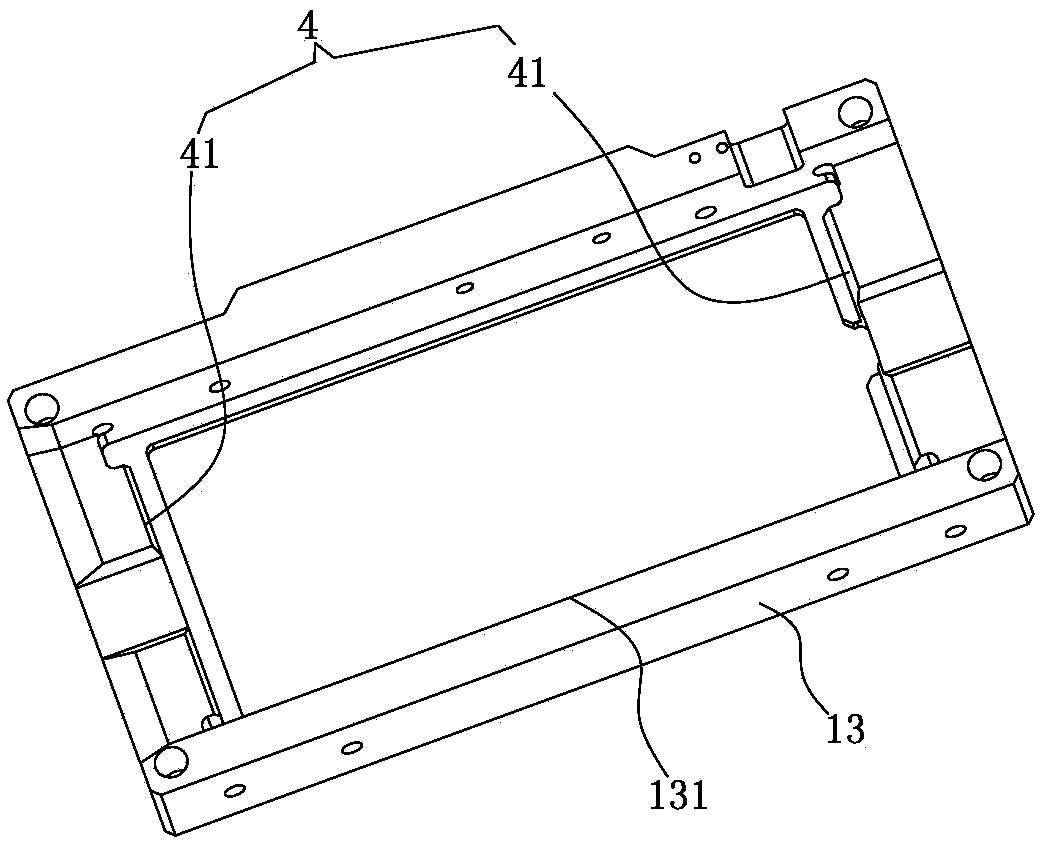

[0021] Described frame 1 comprises base frame 11, some guide rods 12 that are installed on the base frame 11 and the top board 13 that is fixed on guide rod 12 tops and the belt base assembly 14 that is fixed on base frame 11, and this belt base assembly 14 wears on A belt 15 is provided with a jig 16 on the belt 15, wherein a window 131 for exposing the belt 15 is provided on the top plate 13; The support plate 141 and the belt seat 142 fixed on the support plate 141 are provided with a belt groove 143 for the belt to pass through. The side of the top plate 13 is provided with a detection probe 17. When the detection probe 17 detects that the jig 16 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com