Portable type goods loading device for metal thin plates

A metal thin plate, portable technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of easy stepping on air, accidents, hidden safety hazards, high maintenance costs, etc., to achieve strong novelty, low maintenance costs, and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

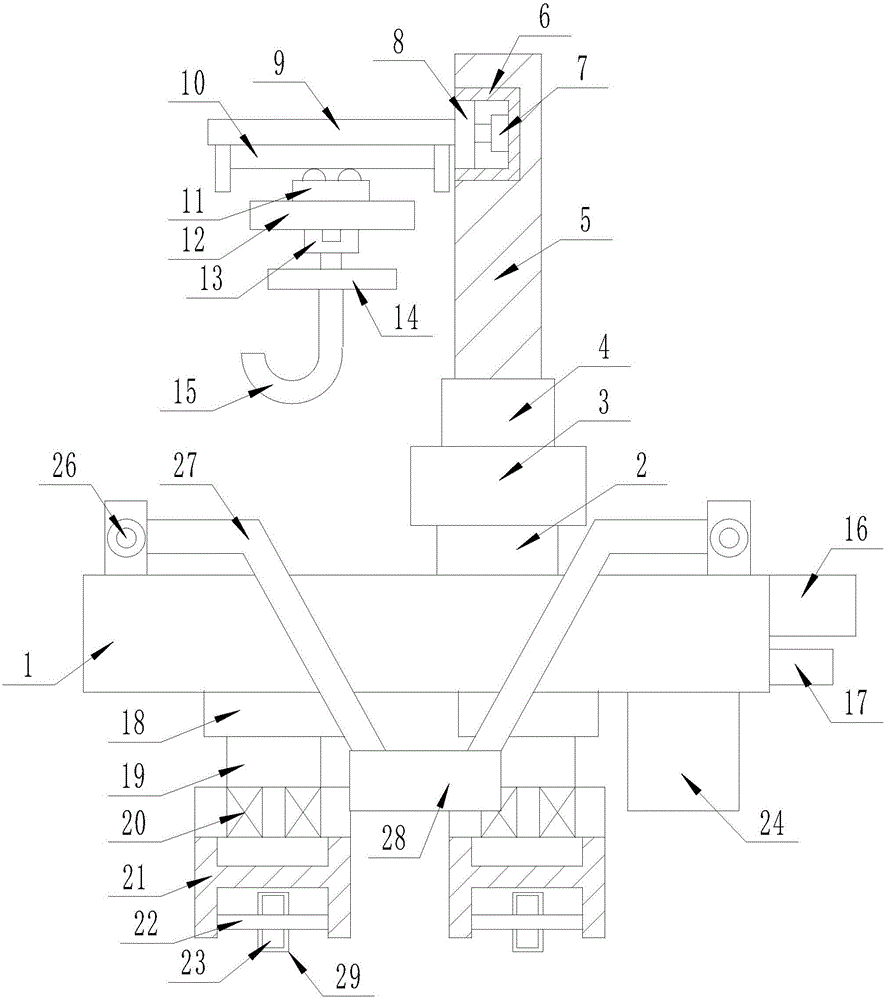

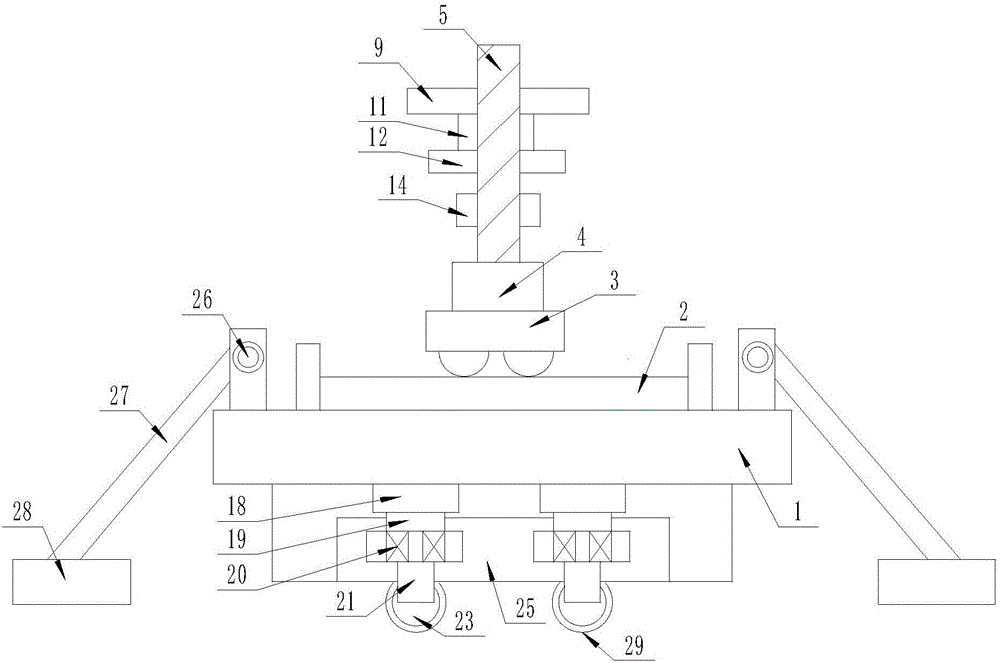

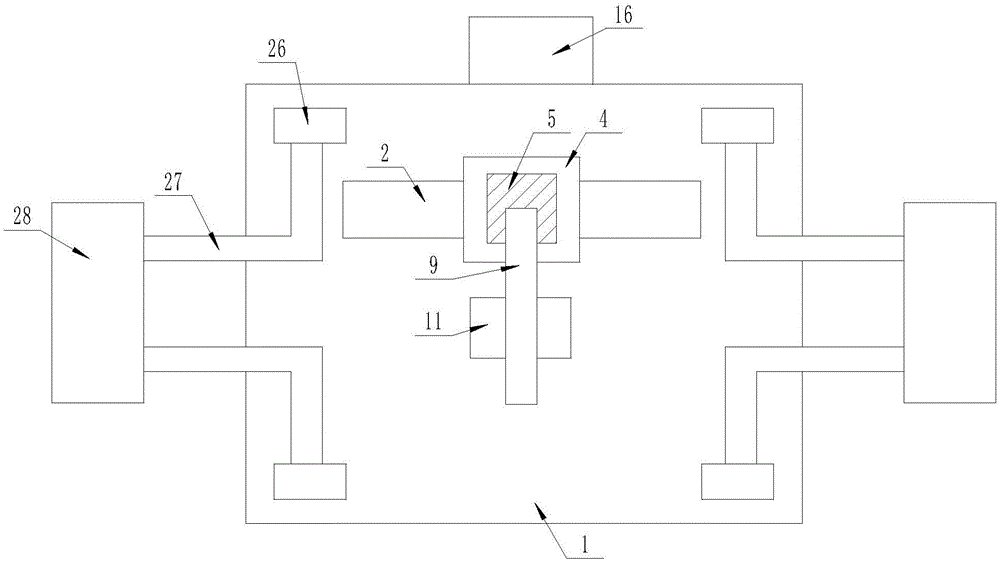

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 As shown, a portable sheet metal loading device includes a loading plate (1), and one side of the upper surface of the loading plate (1) is provided with a horizontal slide rail (2), and on the horizontal slide rail (2) A No. 1 electric trolley (3) is provided, and a No. 1 installation block (4) is provided on the upper surface of the No. 1 electric trolley (3), and a vertical rod (5) is embedded on the upper surface of the No. 1 installation block (4). A circular groove (6) is processed on the surface of one side of the vertical rod (5) and near the upper end, and a linear motor (7) with a telescopic end in a horizontal direction is arranged in the circular groove (6). The telescopic end of the motor (7) is provided with a connecting plate (8) matched with the circular groove (6), and a horizontal plate (9) is arranged on one side surface of the connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com