Feeding method for full-automatic feeding assembly line

A fully automatic, assembly line technology, applied in the field of feeding, can solve the problems of heavy repetition and short manoeuvring time, and achieve the effect of improving suction efficiency, improving production efficiency and ensuring the success rate of suction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings, and the aforementioned and other objects, features, aspects and advantages of the present invention will become more apparent, so that those skilled in the art can implement them with reference to the description.

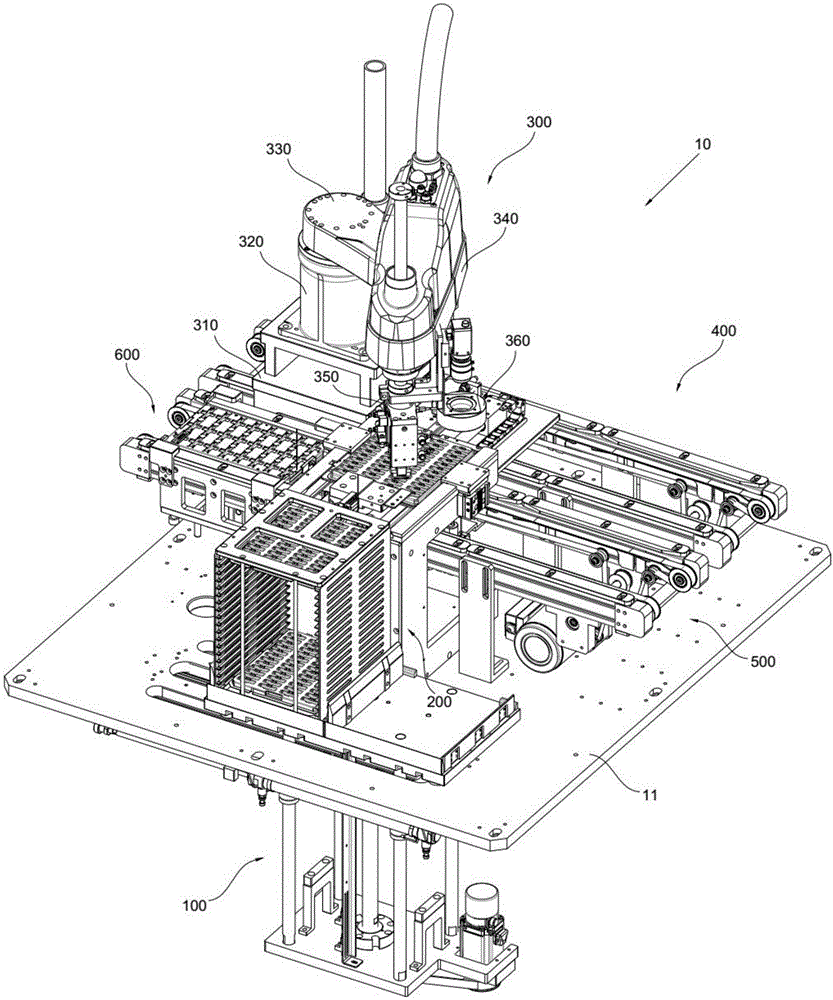

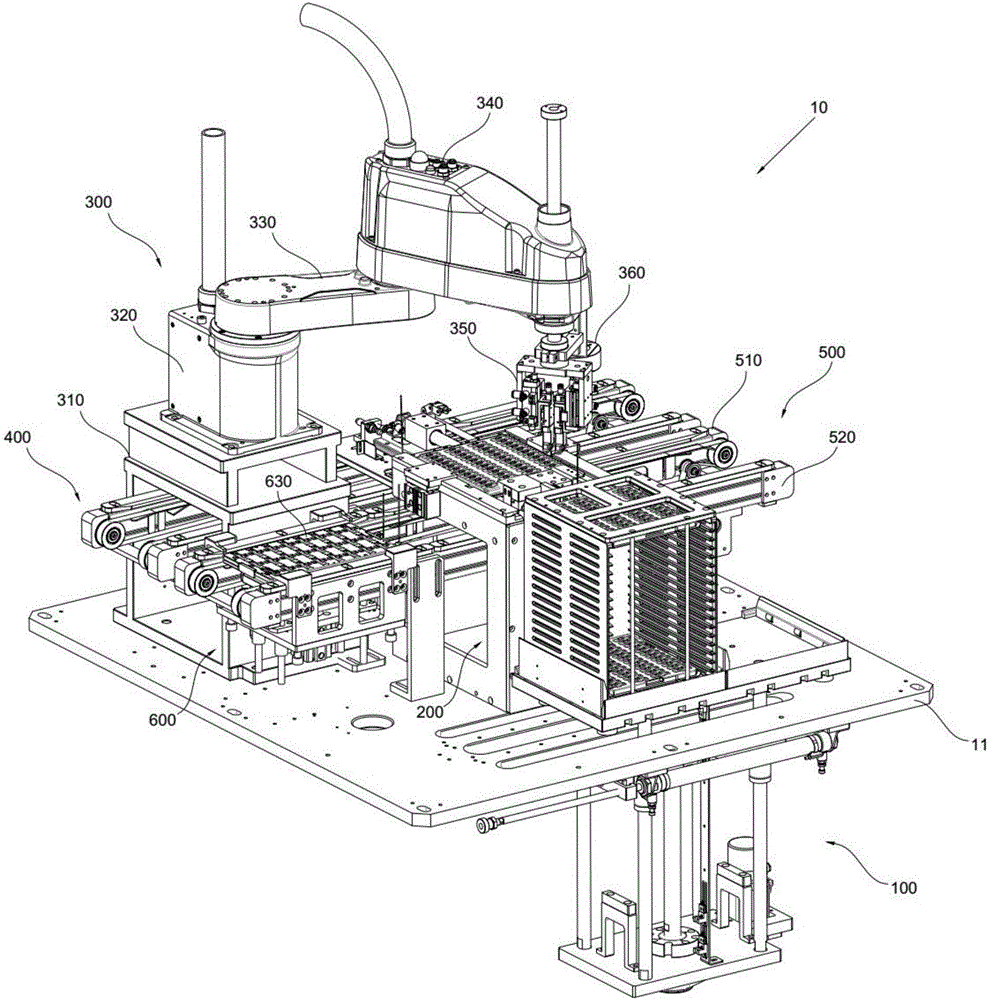

[0036] refer to figure 1 , figure 2 and Figure 10 , the fully automatic feeding line 10 includes:

[0037] Control System;

[0038] work platform 11;

[0039] The feeding line 500 and the return line 400 are arranged side by side, and the carrier 630 is conveyed on the feeding line 500 and the return line 400;

[0040] A feeding mechanism 100 for providing a fully loaded tray 115;

[0041] A retrieving mechanism 200 for taking out a full tray 115 from the loading mechanism 100 or putting back an empty tray 115; and

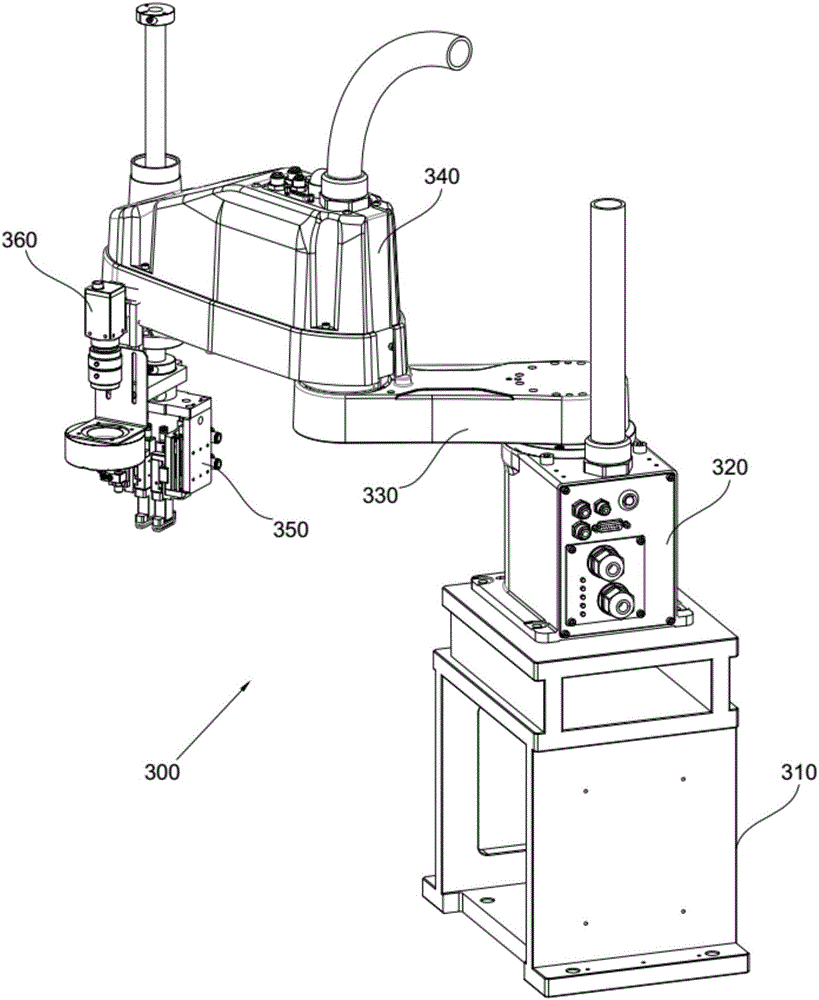

[0042] The manipulator mechanism 300 for transferring spare parts to the carrier 630 on the feeding line 500 from the full-loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com