Rapid foundation pit soil filling device applied to construction sites

A technology for construction sites and bases, which is applied to construction, earth movers/excavators, etc., can solve the problems of slow manual filling speed, achieve high filling efficiency, fast speed, and improve the effect of filling pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

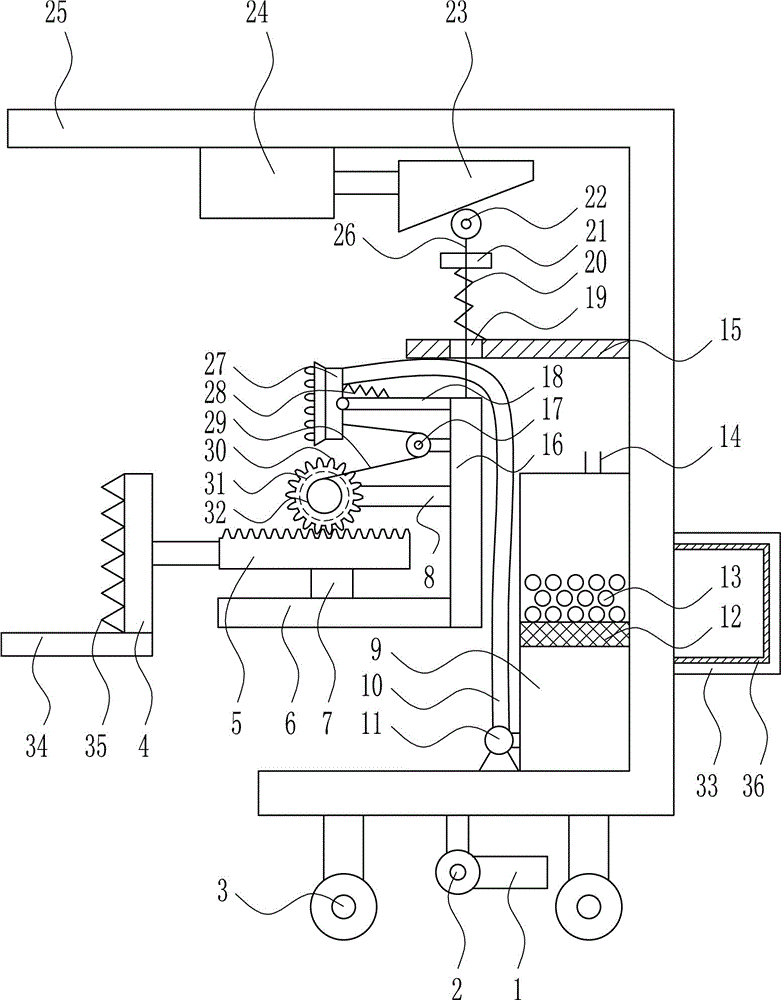

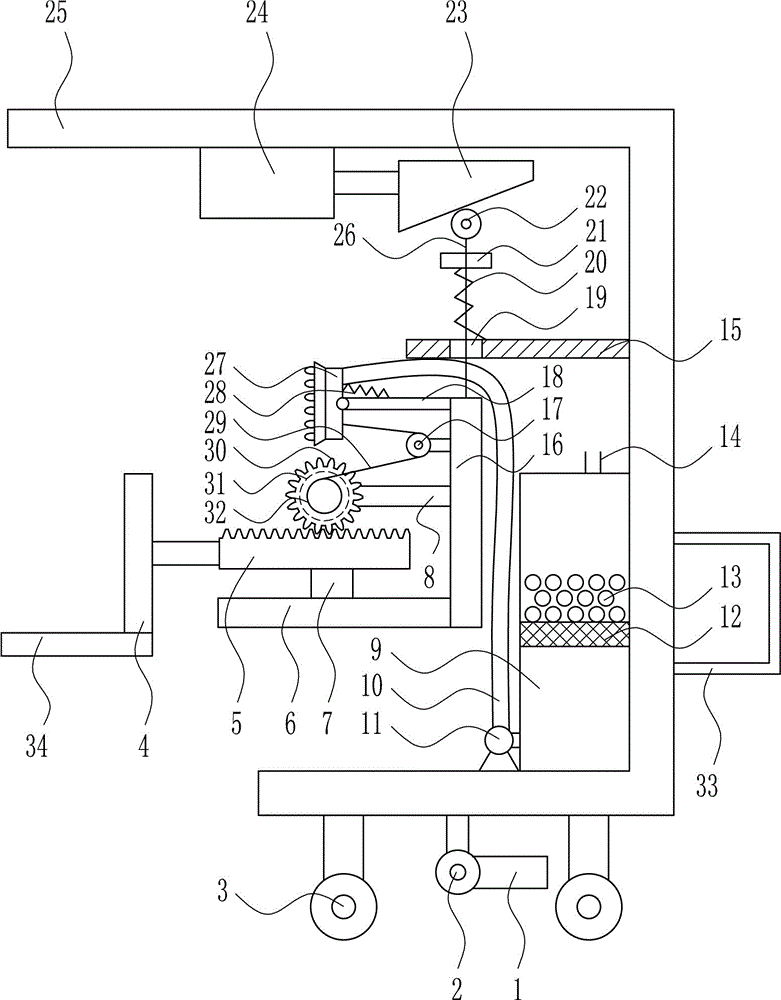

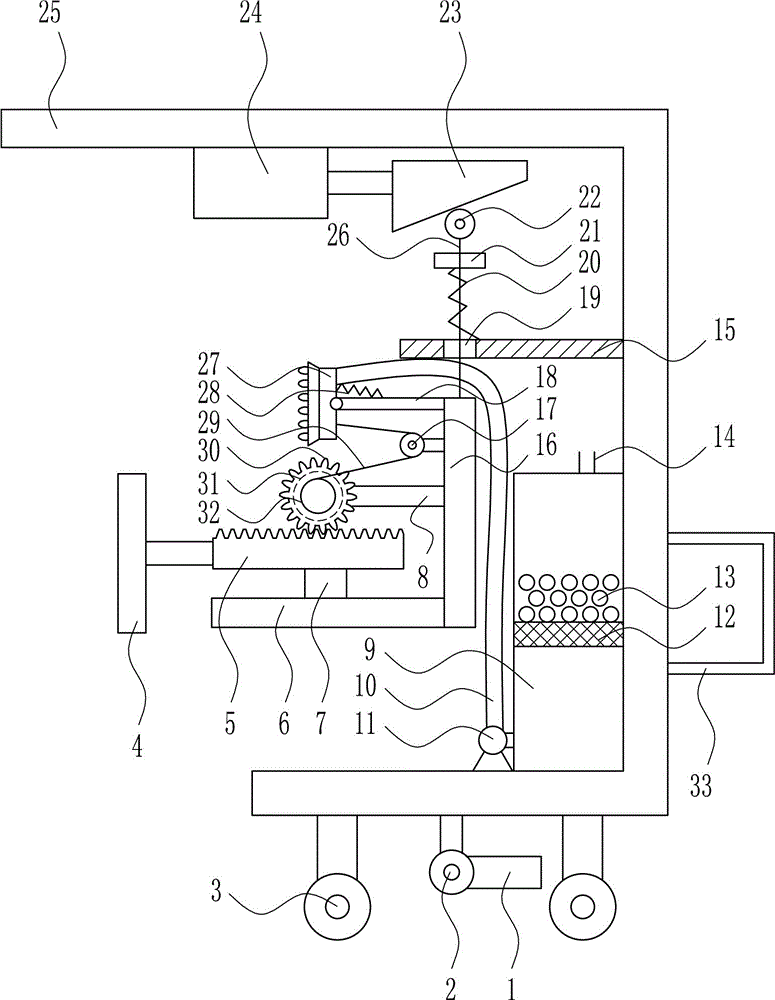

[0032] A rapid soil filling device for bases on construction sites, such as Figure 1-5As shown, it includes friction block 1, electric wheel 2, wheel 3, push plate 4, rack 5, slide rail 6, slider 7, connecting rod 8, purification box 9, hose 10, suction pump 11, filter Net 12, air outlet pipe 14, guide plate 15, fixed plate 16, fixed pulley 17, pole 18, first elastic element 20, fixed block 21, contact roller 22, wedge block 23, cylinder 24, cart 25, lifting Rod 26, dust suction cover 27, second elastic element 28, stay cord 29, gear 30, rotating motor 31, reel 32 and handle 33; Both sides of cart 25 bottom left and right sides are all provided with wheel 3, and cart 25 bottom An electric wheel 2 is arranged between the wheels 3, and the electric wheel 2 is provided with a friction block 1, the right side of the cart 25 is provided with a handle 33, and the inner right wall of the cart 25 is provided with a guide plate 15 and a purification box 9, and the guide plate 15 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com