Friction energy consumption beam-column joint for prefabricated structure

A technology of beam-column joints and prefabricated structures, which is applied in the direction of building types, building components, building structures, etc., can solve problems such as limited application, and achieve the effects of good economy, not easy to fatigue damage, and low processing and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

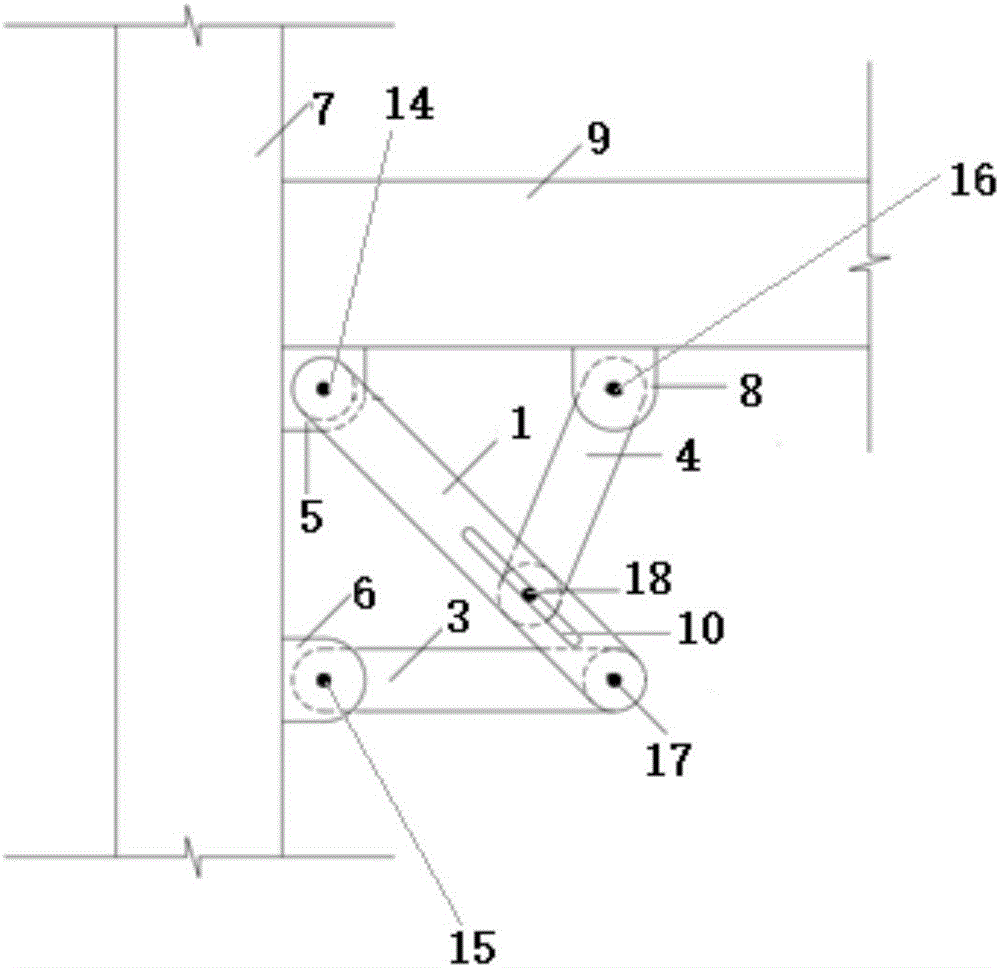

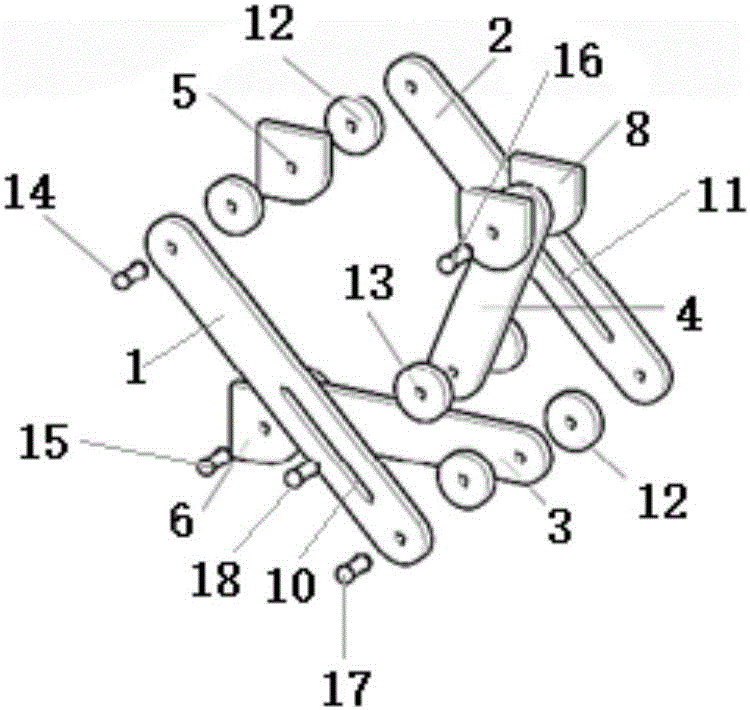

[0029] Such as Figure 1-Figure 2 As shown, a prefabricated structural frictional energy-dissipating beam-column joint includes an additional frictional energy-dissipating device located in the area of the hinged beam-column joint. The additional frictional energy-dissipating device includes a slotted transmission rod I1, a slotted transmission rod II2, The transmission rod I3, the transmission rod II4 and the embedded steel plate I5 located at the hinged beam-column node, the two sides of the embedded steel plate I5 are respectively hinged with one end of the slotted transmission rod I1 and the slotted transmission rod II2, The other ends of the slotted transmission rod I1 and the slotted transmission rod II2 are hinged to one end of the transmission rod I3, and one end of the transmission rod I3 is located between the slotted transmission rod I1 and the slotted transmission rod Between II2, the other end of the transmission rod I3 is located between the two pre-embedded st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com