Combination of Vertical Well Volume Fracturing and Linear Water Injection to Develop Ultra-Low Permeability Reservoirs

A volume fracturing and permeable oil technology, which is applied in the development field of ultra-low permeability reservoirs, can solve the problems of low oil production rate, single fracture, and low volume, and achieve the goal of increasing oil production rate, enhancing water injection capacity, and increasing single well production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

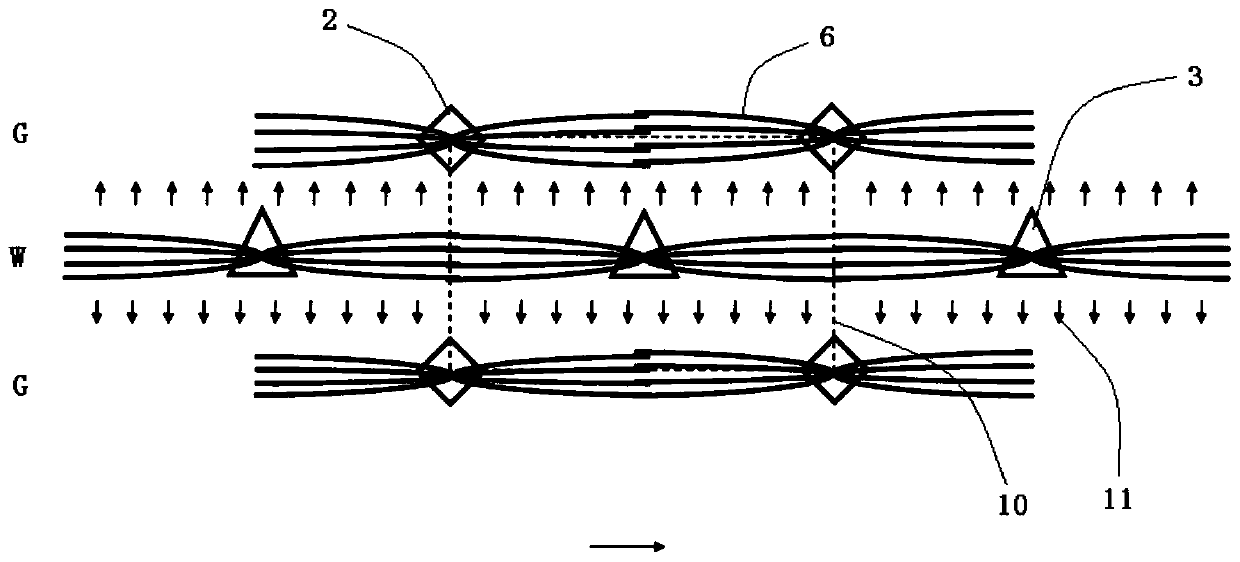

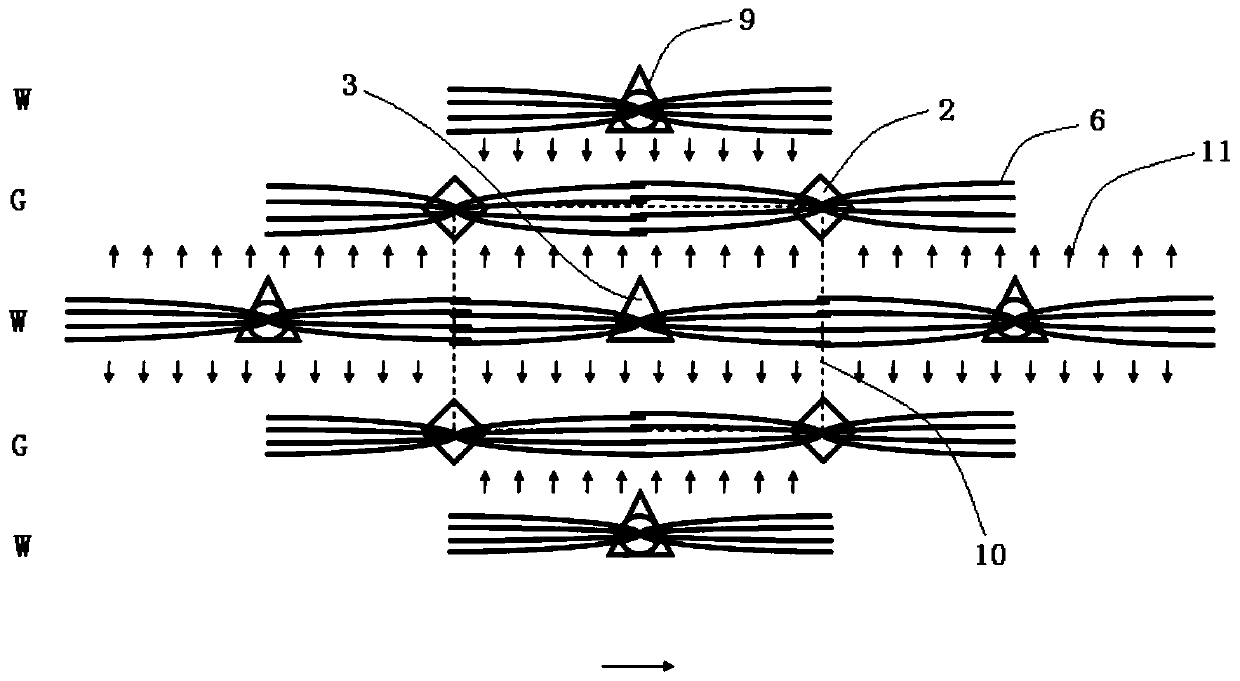

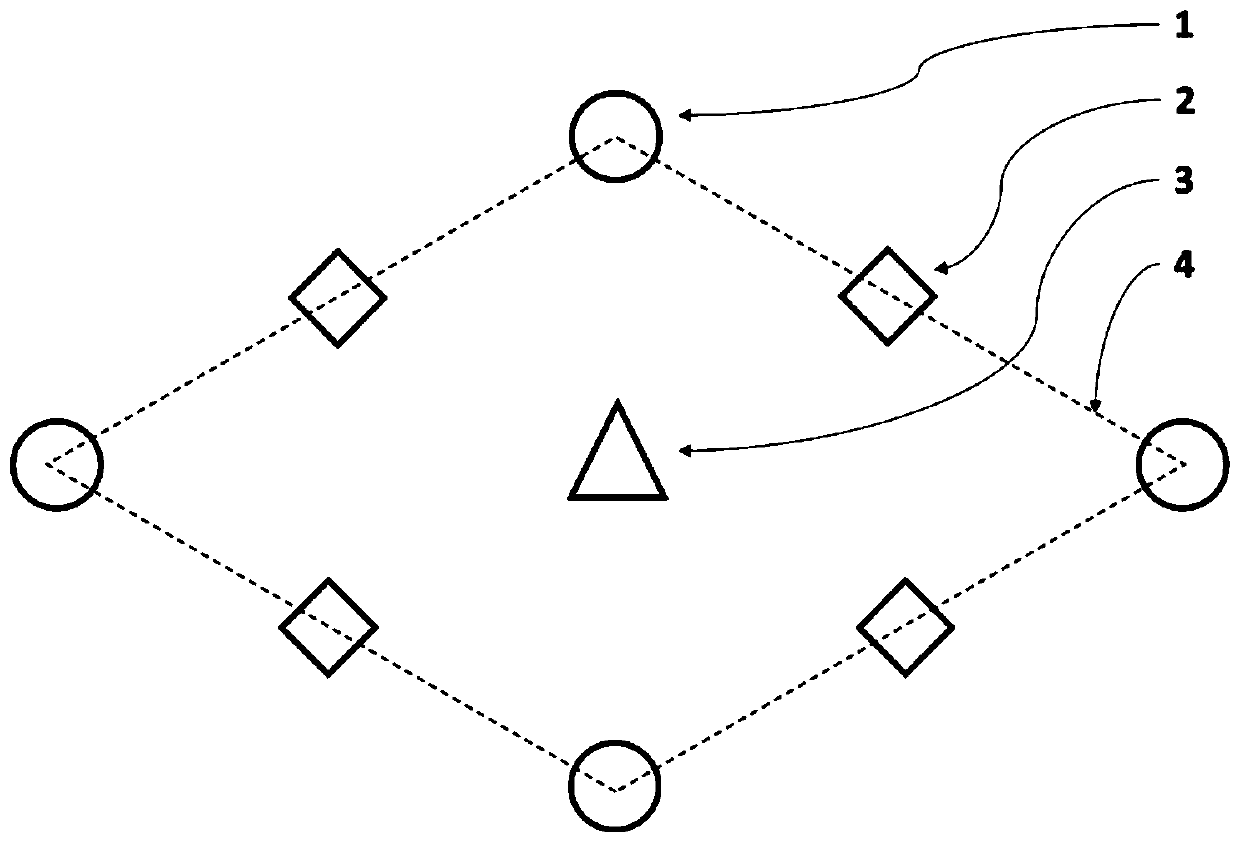

[0037] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0038]Aiming at the problems existing in the development of ultra-low permeability reservoirs, such as low initial production, low production degree, difficulty in energy supplementation, poor economic benefits, low oil recovery rate, and low recovery factor, the present invention provides a vertical well volume fracturing and linear The method of developing ultra-low permeability reservoirs by water flooding combination, the applicable ultra-low permeability reservoirs are continental multi-layer sandstone unsaturated reservoirs, without edge bottom water and gas cap, sand body thickness 2m-80m, average air permeability of the reservoir is less than 1.0mD-1.5mD, average porosity 8.0%-14.0%; the difference between the maximum and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com