Water-spraying guide vane capable of improving deviation of optimum operating condition of water turbine

An optimal working condition, hydraulic turbine technology, applied in the design and manufacture of hydraulic turbines, mechanical design and manufacturing, can solve the problems of hydraulic performance decline of hydraulic turbines, guide vane outlet angle and runner blade inlet placement angle no longer match, etc., to improve hydraulic performance , Improve the effect of flow field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described by the following examples. This example is only used to further illustrate the present invention, but it cannot be interpreted as limiting the protection scope of the present invention. Essential improvements and adjustments belong to the protection scope of the present invention.

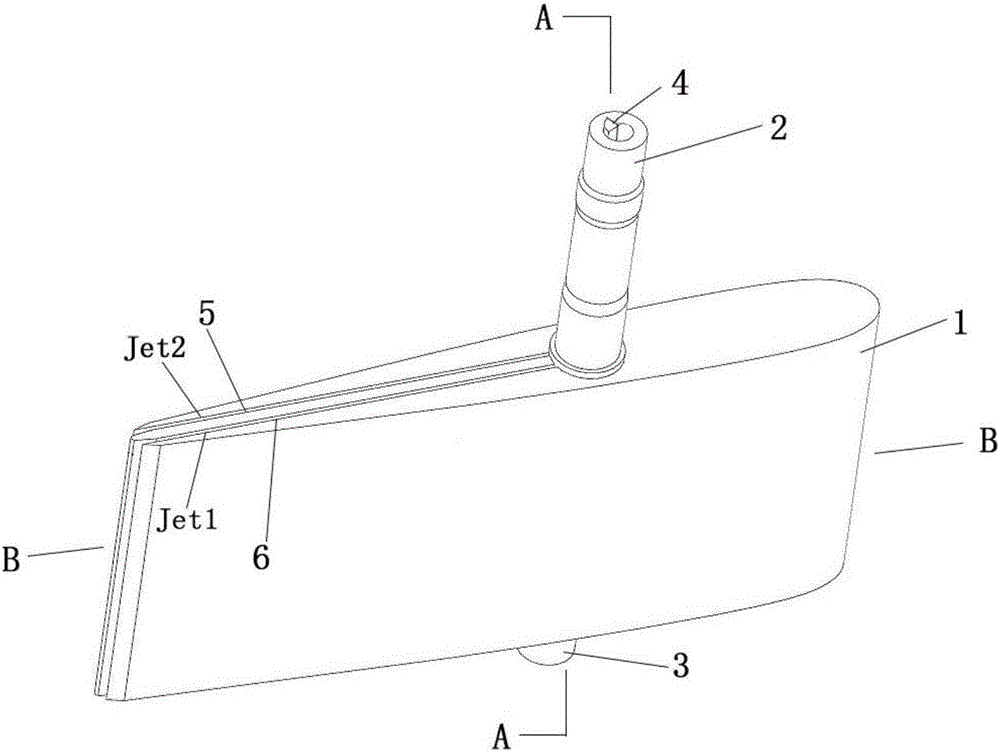

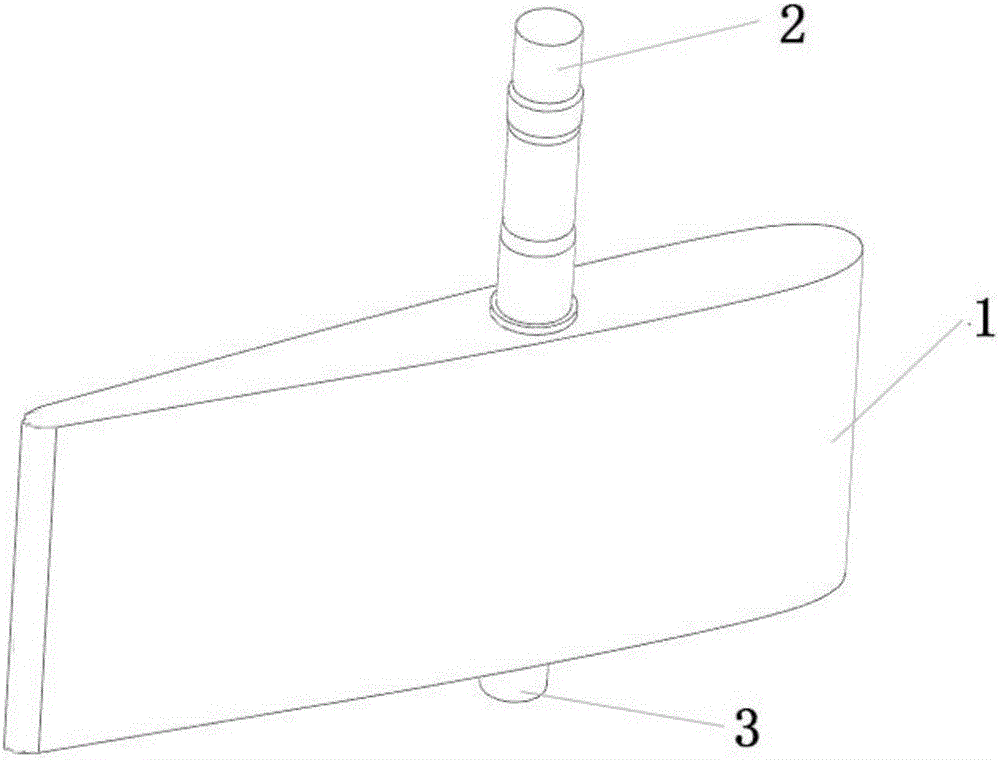

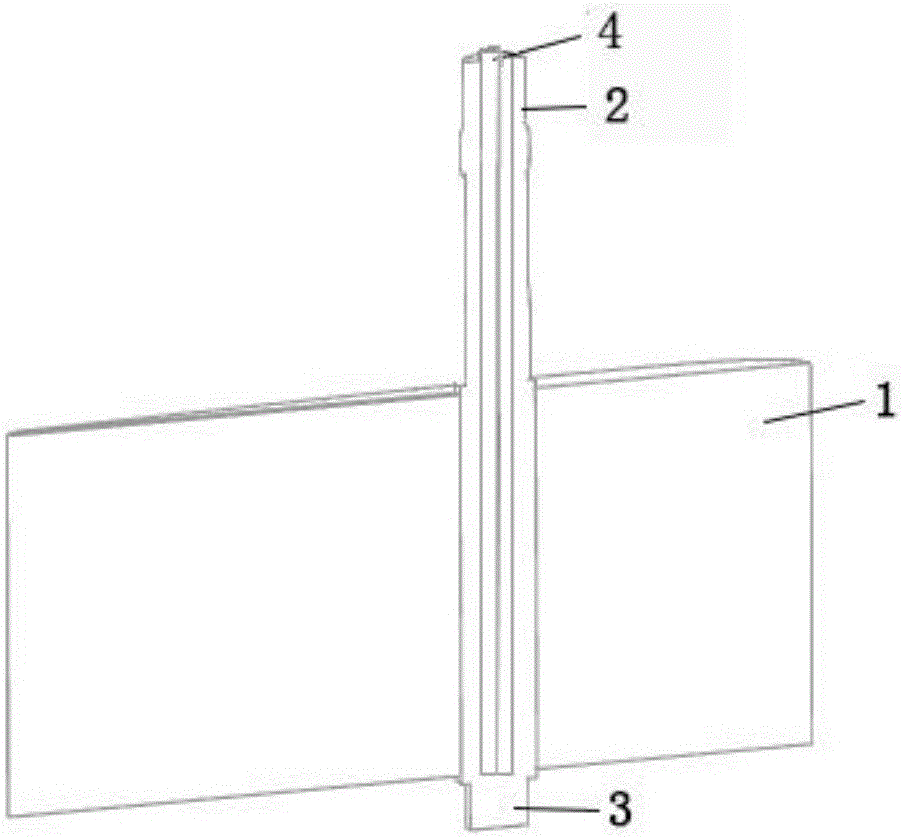

[0033] to combine Figure 1 to Figure 12 .

[0034] Such as figure 1 shown in figure 2 On the basis of the movable guide vane structure of the existing radial water guiding mechanism shown, a hole with a diameter of Φs is designed at the axis of the guide vane pivot and two grooves are designed on the guide vane body to form jet1 and jet2 nozzles the runner. During the operation of the turbine, it is necessary to control the working state of the two nozzles through the cock shaft according to the working conditions. When the turbine is running away from the optimal working condition, adjust the flow rate of the nozzle according to the change o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com