a brake

A technology of brakes and joints, applied in the direction of brake types, axial brakes, brake parts, etc., can solve the problems of reducing transmission efficiency, complicated burr process, increasing drag loss of friction plates, etc., and achieves the goal of improving efficiency and reducing drag loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the implementation process of the present invention is described in further detail:

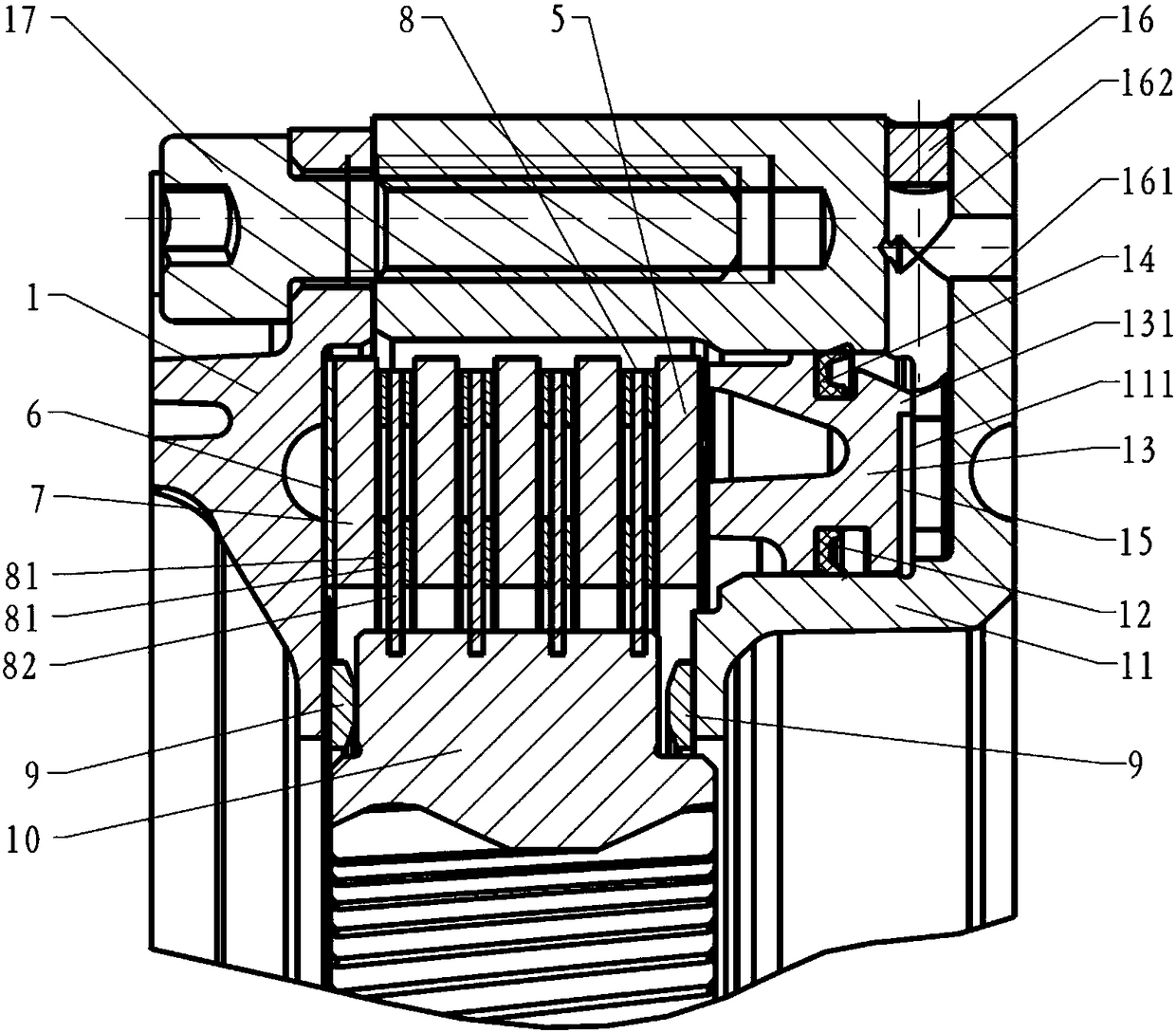

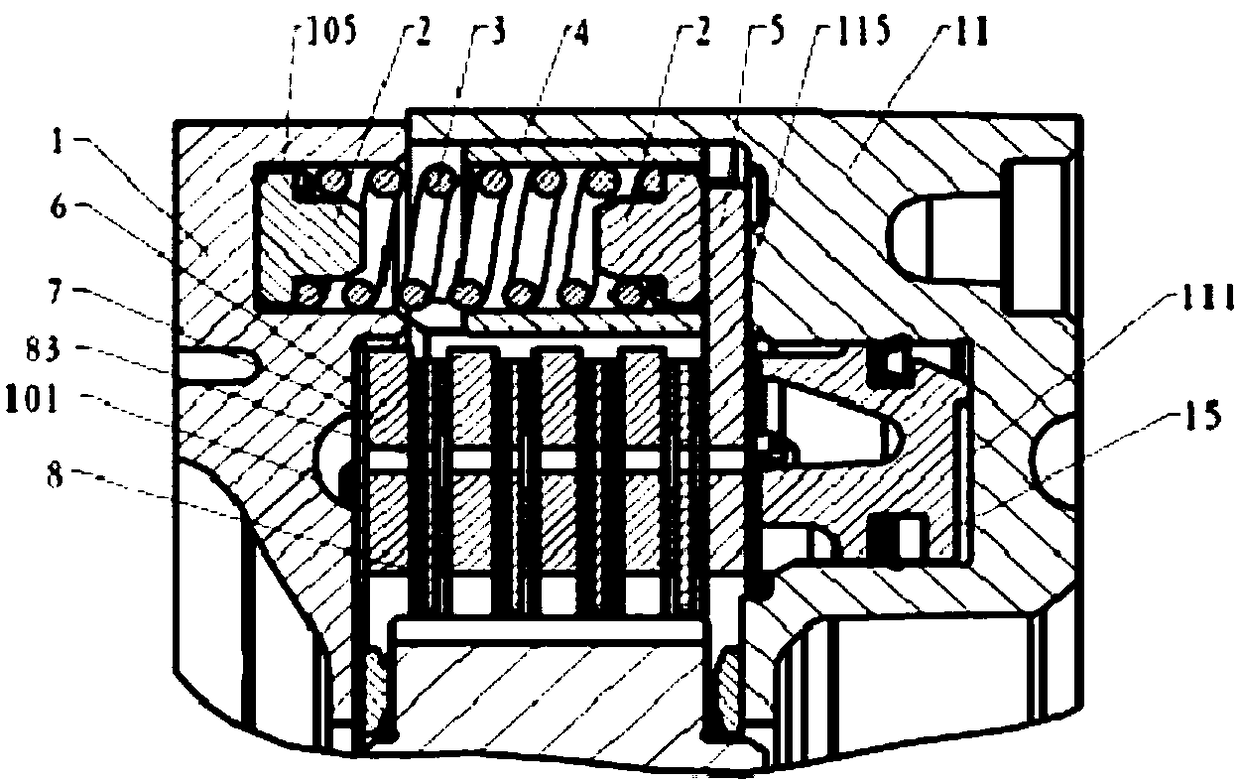

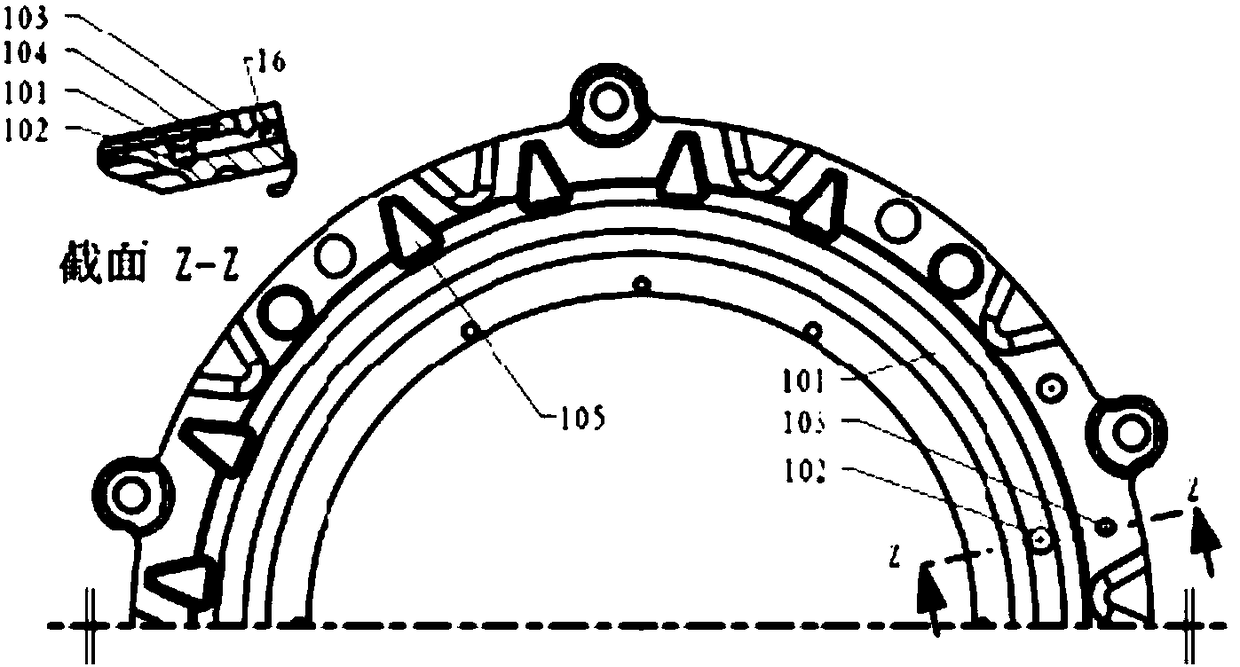

[0029] see Figure 1 to Figure 6 , the brake includes a back plate housing 1 and a piston housing 11, which are connected together by fasteners 17 and form a friction plate installation space, in which the dual plates 7 and friction plates 8 are alternately arranged, and the dual plates 7 pass through it The second spline tooth 71 is installed in the keyway 113 on the piston housing 11; the friction plate 8 is composed of the middle base body 82 and the friction material 81 attached to both sides, and is installed on the inner spline tooth through the inner spline tooth on the middle base body 82. On the ring gear 10 , the ring gear 10 is axially positioned according to a method known in the industry, and a flow equalization plate 6 is installed between the outermost dual plate and the back plate housing 1 .

[0030] An oil inlet groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com