Single-piston-rod damper

A technology of damper and single rod, which is applied in the direction of shock absorber, shock absorber, liquid shock absorber, etc., can solve the problem of unsatisfactory energy consumption of STF damper, achieve excellent mechanical properties, simple production process, and low load wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

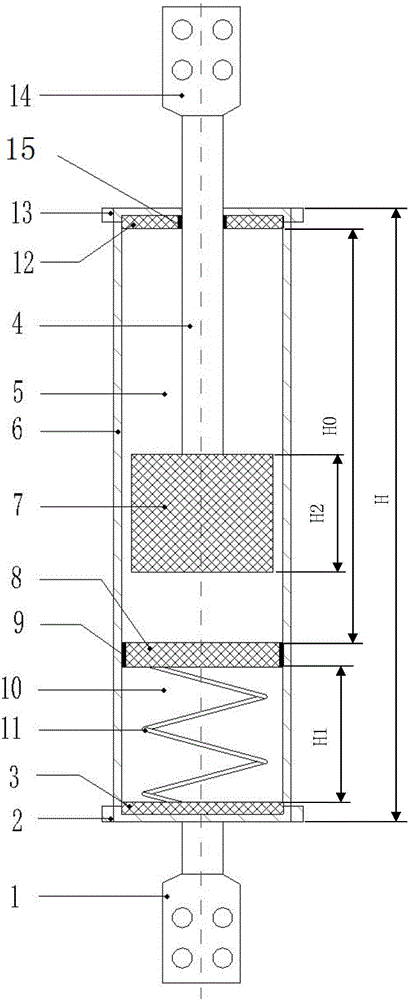

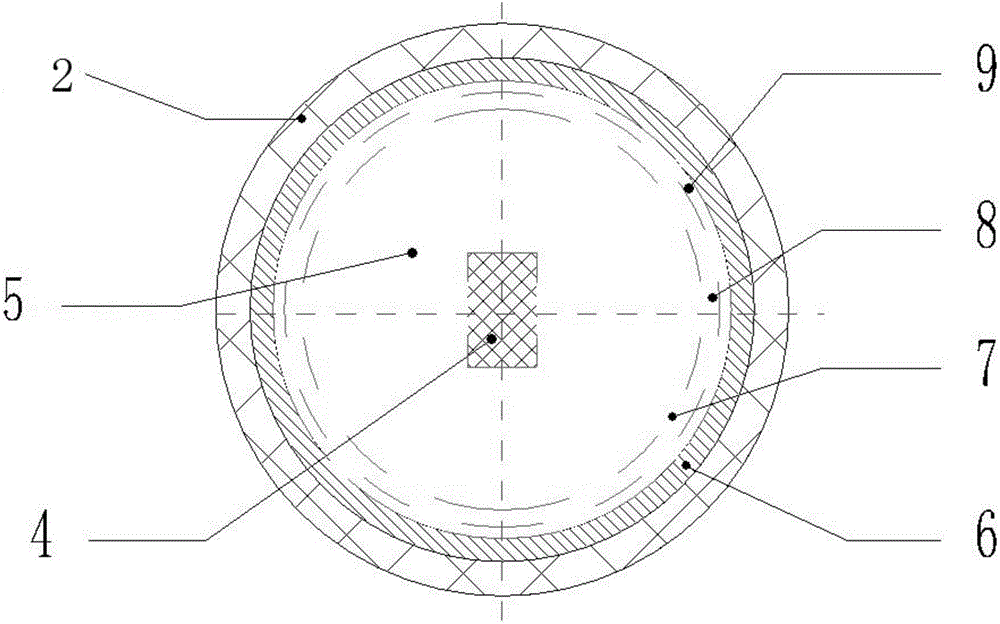

[0032] Example: such as figure 1 , figure 2 As shown, the present invention includes a single rod damper, comprising:

[0033] The cylinder 6 is divided into a working chamber 5 and a compensation chamber 10, the two chambers are separated by a floating piston 8 sealed with the cylinder 6, and the working chamber 5 is filled with STF liquid;

[0034] Piston rod 4, one end is placed in the working chamber 5 in the cylinder body 6, its end is connected to the working piston 7, and the other end is placed outside the cylinder body 6, connected to the connecting piece 1;

[0035] An elastic member 11 is arranged in the compensation chamber 10, one end of the elastic member 11 is connected to the floating piston 8, and the other end is connected to the rubber piston I3 placed at the end of the cylinder 6; the elastic member 11 adopts an SMA spring;

[0036] The height H1 of the compensation chamber 10 is set according to actual engineering needs, and is 1 / 4-1 / 3 of the height H o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com