Double-gear clutch device and transmission assembly

A technology of clutch device and speed ratio, applied in the direction of transmission device, gear transmission device, belt/chain/gear, etc., can solve the problems of large engine speed fluctuation, small torque output, large engine speed drop, etc., to ensure efficient operation. Performance range, meeting speed ratio requirements, and reducing the effect of speed fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions of each exemplary embodiment provided by the present invention with reference to the accompanying drawings in the embodiments of the present invention. In the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

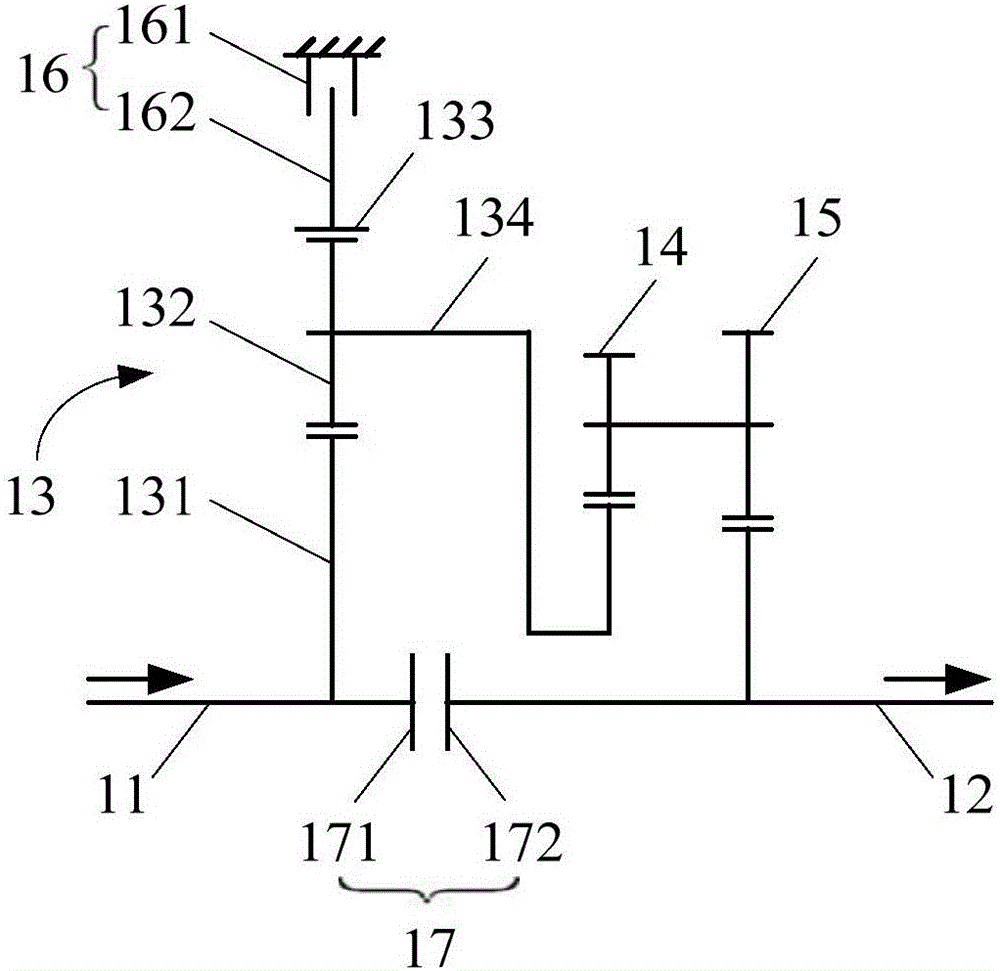

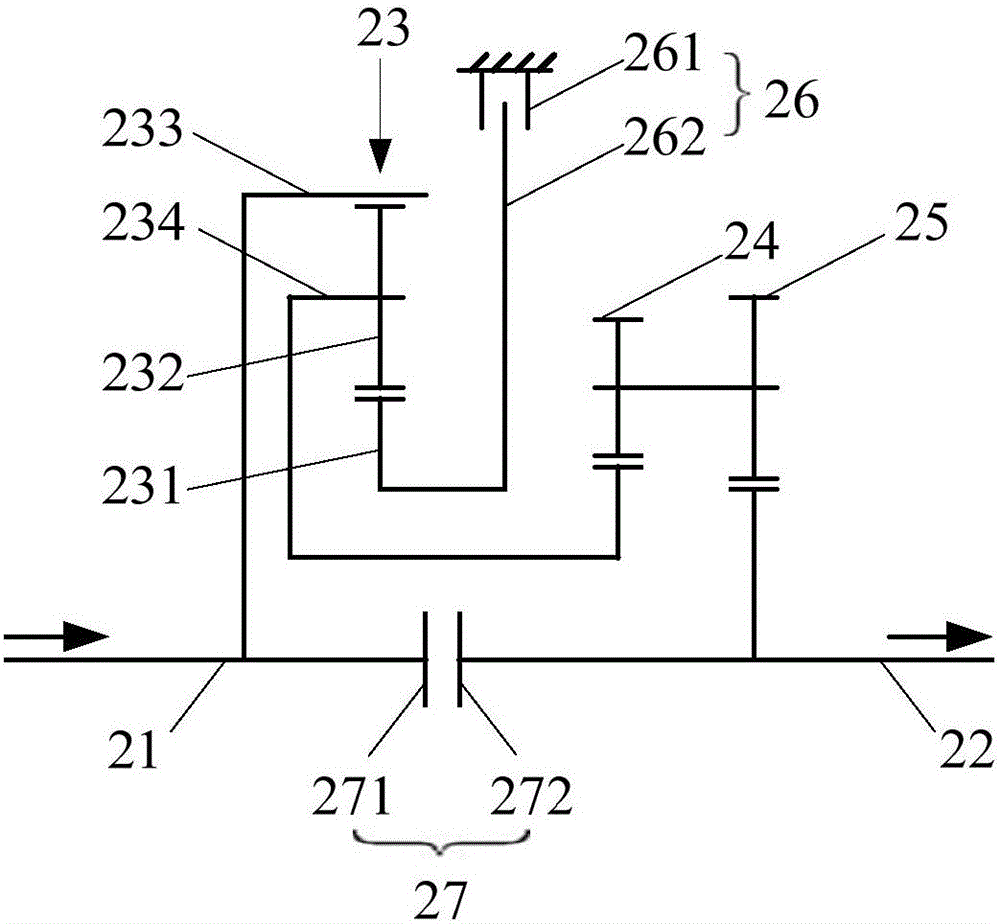

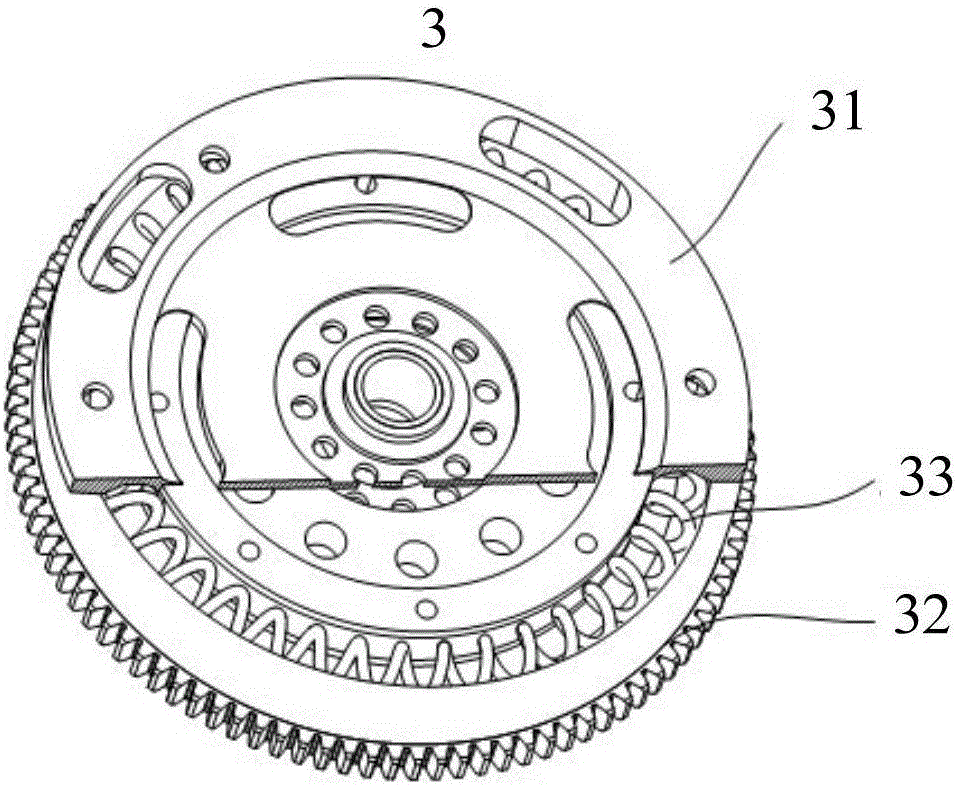

[0019] see figure 1 , is the double block clutch device of the first embodiment of the present invention. The double-speed clutch device can be connected between the output shaft of the engine and the input shaft of the transmission gear set as an independent part of the power plant, for receiving power from the engine, and passing through the transmission gear set and the final reducer connected with the transmission gear set , differential, etc. output power to drive the load. Wherein, the power device applicable to the double-speed clutch device may be a vehicle or a ship, but of course it is not limited thereto; correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com