Semi-floating drive axle for electric sightseeing vehicle and electric cargo truck

A technology for electric trucks and electric sightseeing vehicles, which is applied to axles, wheels, vehicle parts, etc., can solve the problems of waste, single drive axle speed ratio, fixed structure, etc., and achieves compact appearance, reduced resource waste, and versatility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

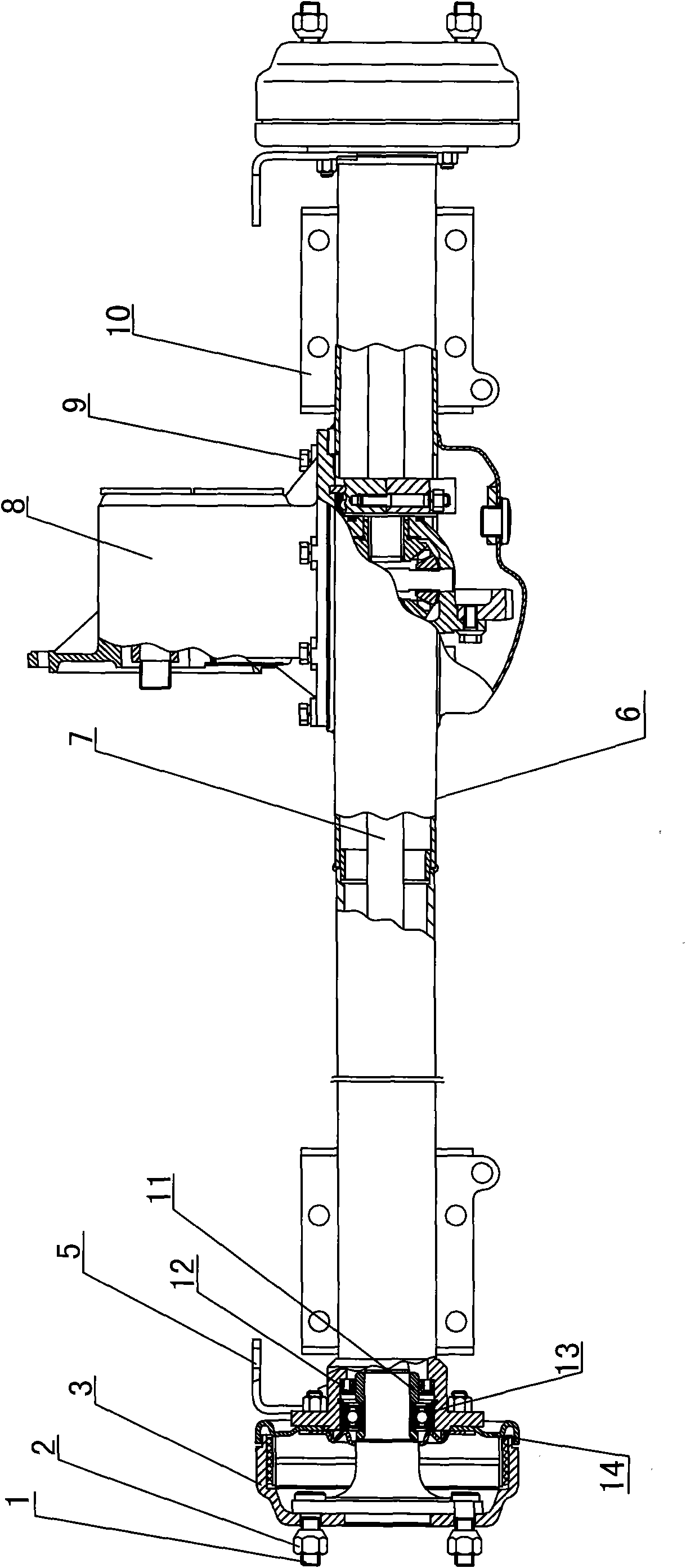

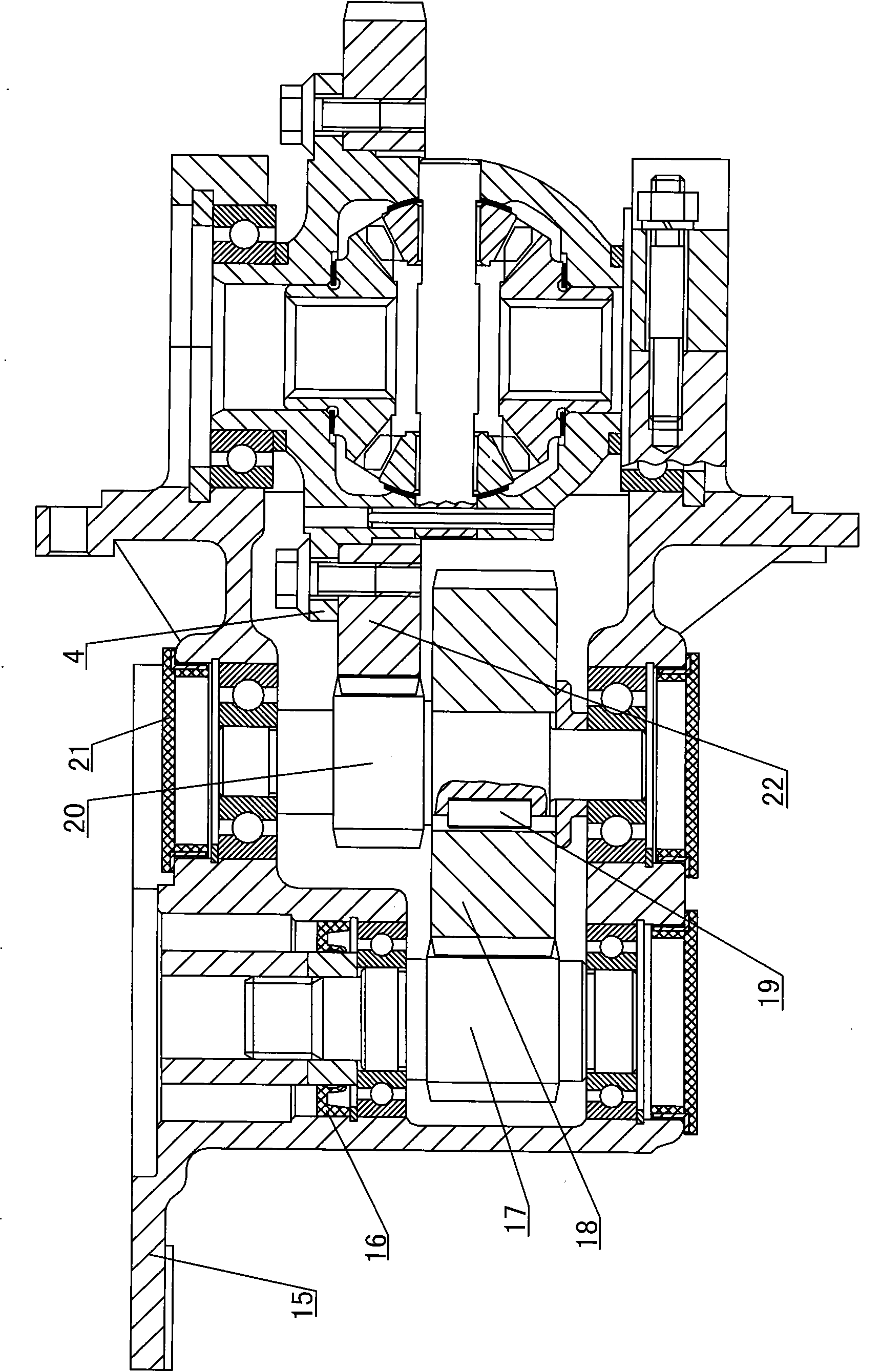

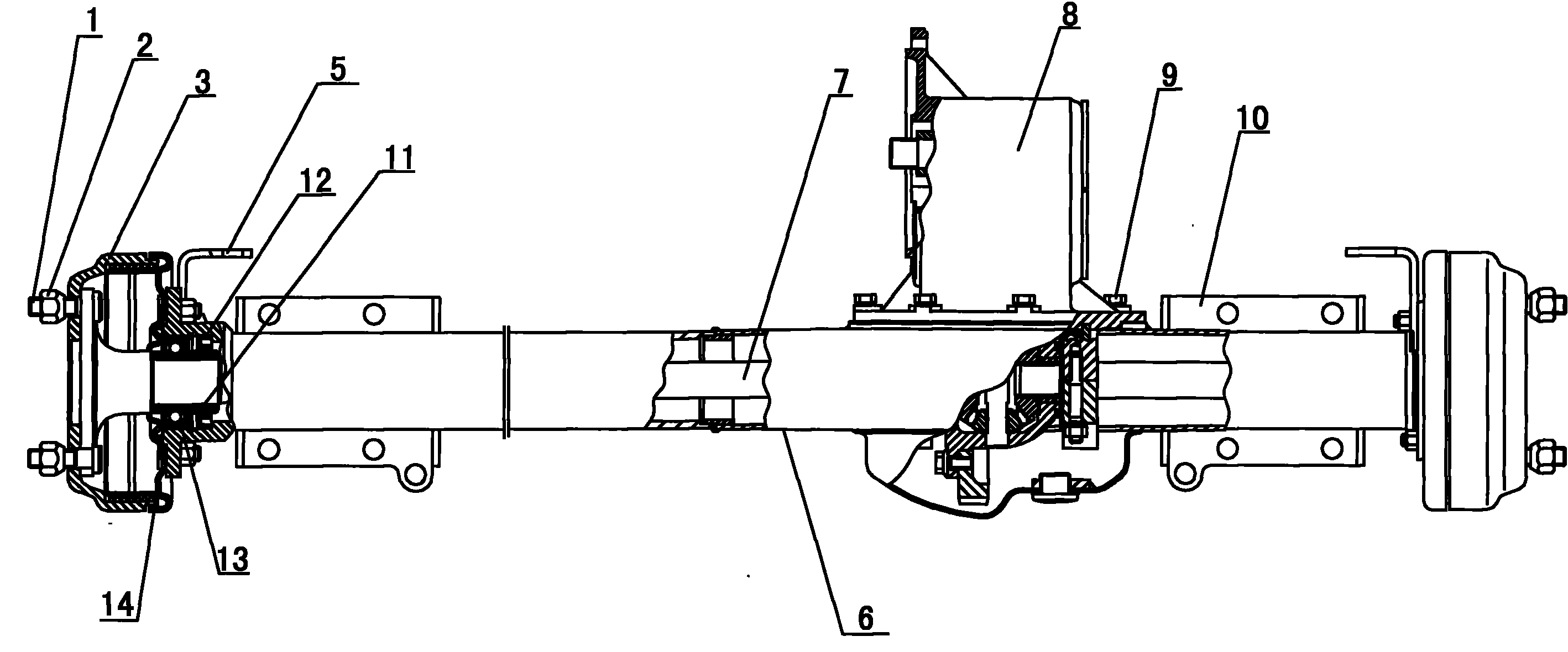

[0012] Such as figure 1 As shown, the semi-floating drive axle for electric sightseeing cars and electric trucks according to the present invention includes a speed reducer 8, an axle housing 6 and a half shaft 7, and the speed reducer 8 is used for power conversion and is connected by bolts 9 is connected with the axle housing 6, and the leaf spring seat 10 is welded on both sides of the axle housing 6. The leaf spring seat 10 is used to bear the load of the whole vehicle and the shock absorber bracket mounting hole is punched on the leaf spring seat 10 to facilitate the installation of the whole vehicle. Installation, through reasonable structural design to make it more versatile, the bearing 13 installed on the outer end of the half shaft 7 can support the half shaft 7 on the axle housing 6; the outer retaining ring 11 is pressed on the bearing 13 , an oil seal 12 is provided on the outer side of the outer retaining ring 11 to seal the drive axle part, which can protect imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com