Full-floating drive axle for electric sightseeing bus or electric cargo truck

A technology for electric trucks and electric sightseeing cars, which is applied to axles, wheels, vehicle parts, etc., can solve problems such as limited carrying capacity and safety accidents, and achieve the effects of improving carrying capacity, high safety factor, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

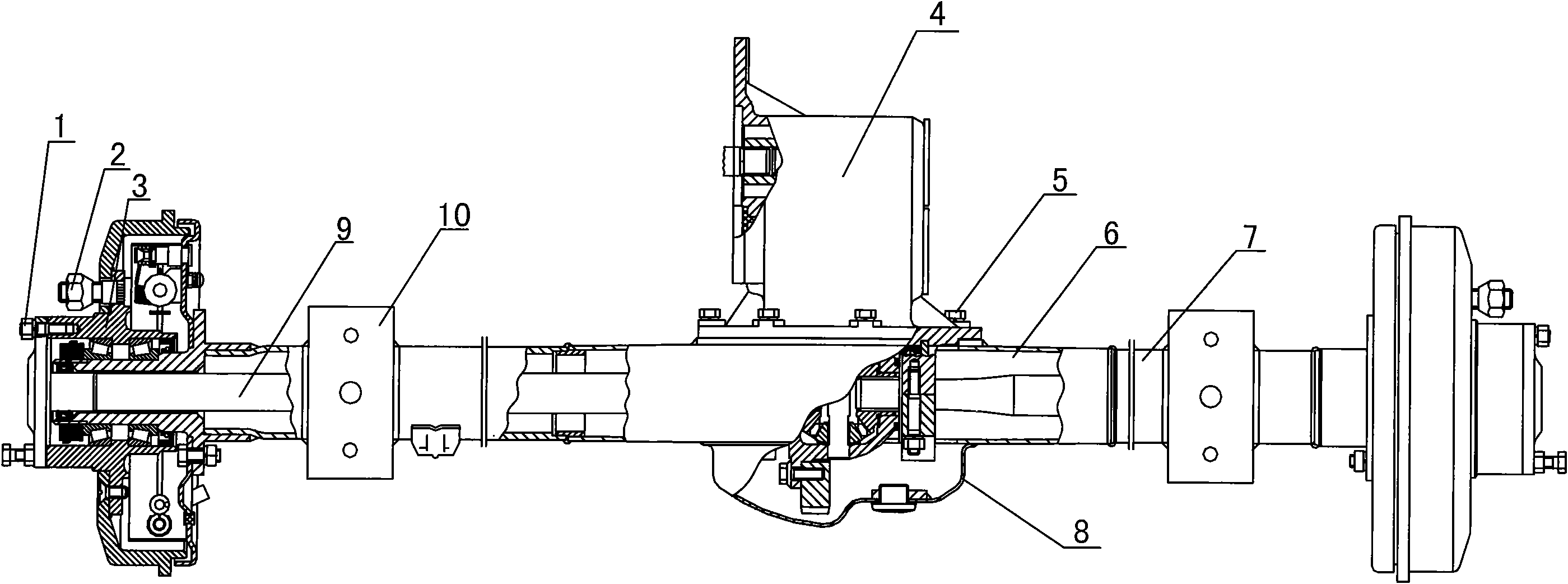

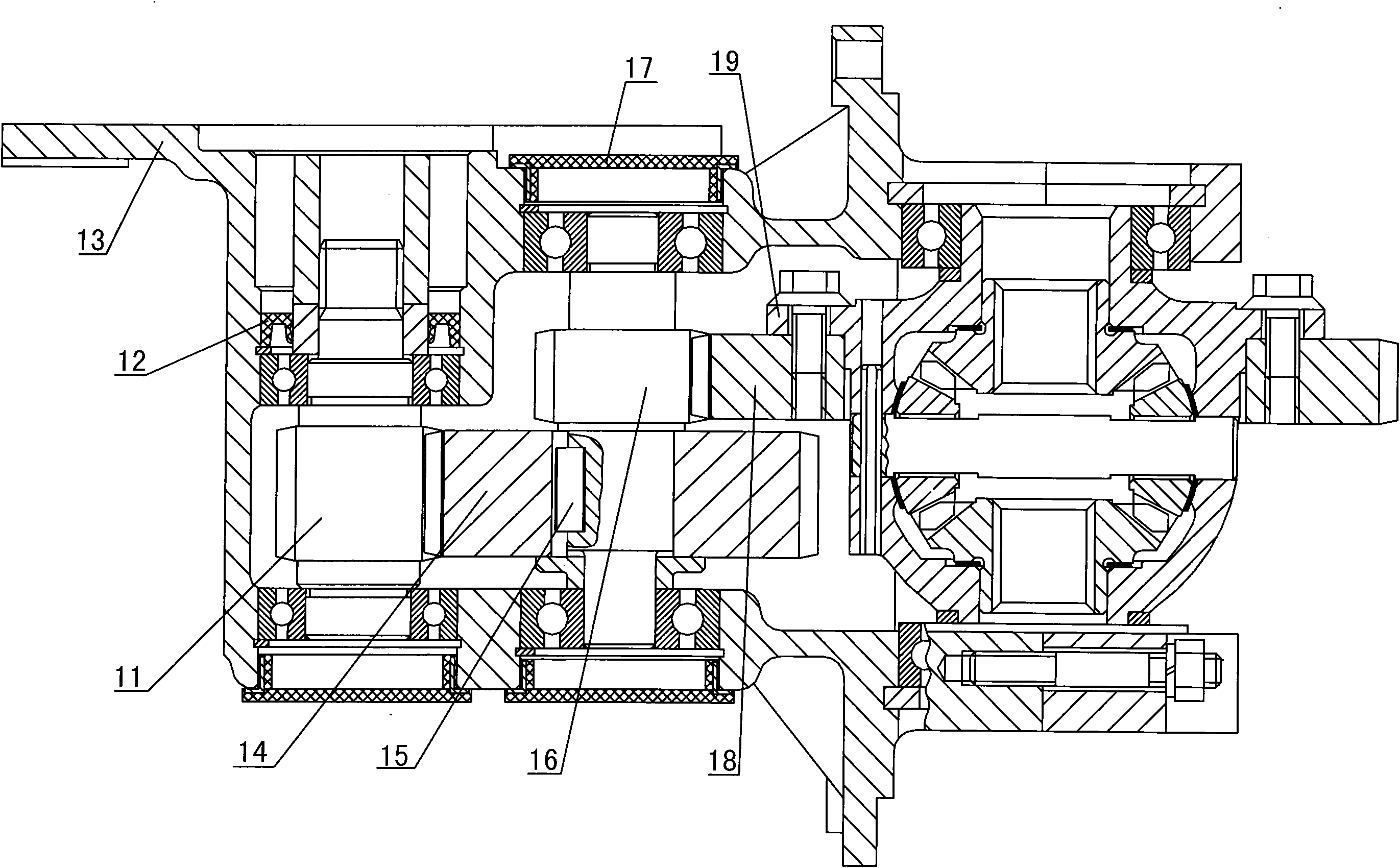

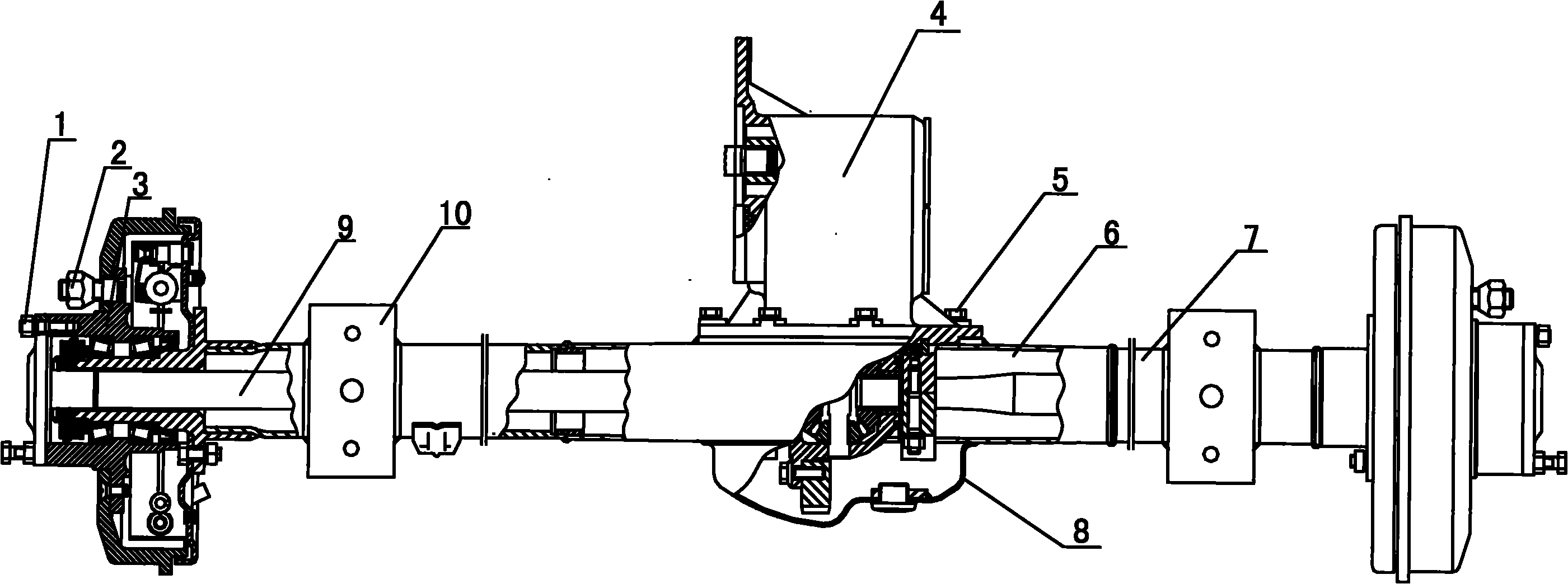

[0012] Such as figure 1 As shown, the full floating drive axle for electric sightseeing cars and electric trucks according to the present invention includes a hub 3, a speed reducer 4, an axle housing 6 and a half shaft 9, and the speed reducer 4 is used for power conversion The axle housing 6 is connected with the axle housing 6 through the bolt 5, the leaf spring seat 10 is welded on both sides of the axle housing 6 and the flange shaft is welded at both ends to cooperate with the hub 3, and the axle housing 6 is composed of the middle section of the axle housing, the axle housing cover 8, the sleeve The pipe 7 and the flange shaft are welded, and it has wider versatility through reasonable structural design. The outer end of the wheel hub 3 is press-fitted with tire bolts 2, and the wheel hub 3 is connected with the half shaft 9 through bolts 1 to make the two Rotating synchronously, the splined end of the axle shaft 9 is inserted into the inside of the reducer 4 , the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com