Power system of crawler tractor

A technology for power systems and tractors, which is applied to motor vehicles, crawler vehicles, control devices, etc., can solve the problems of poor structural stability, high damage rate, maintenance cost and difficulty, and reduce maintenance costs and avoid internal oil temperature rise. High, less susceptible to impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention will be further described by specific embodiment:

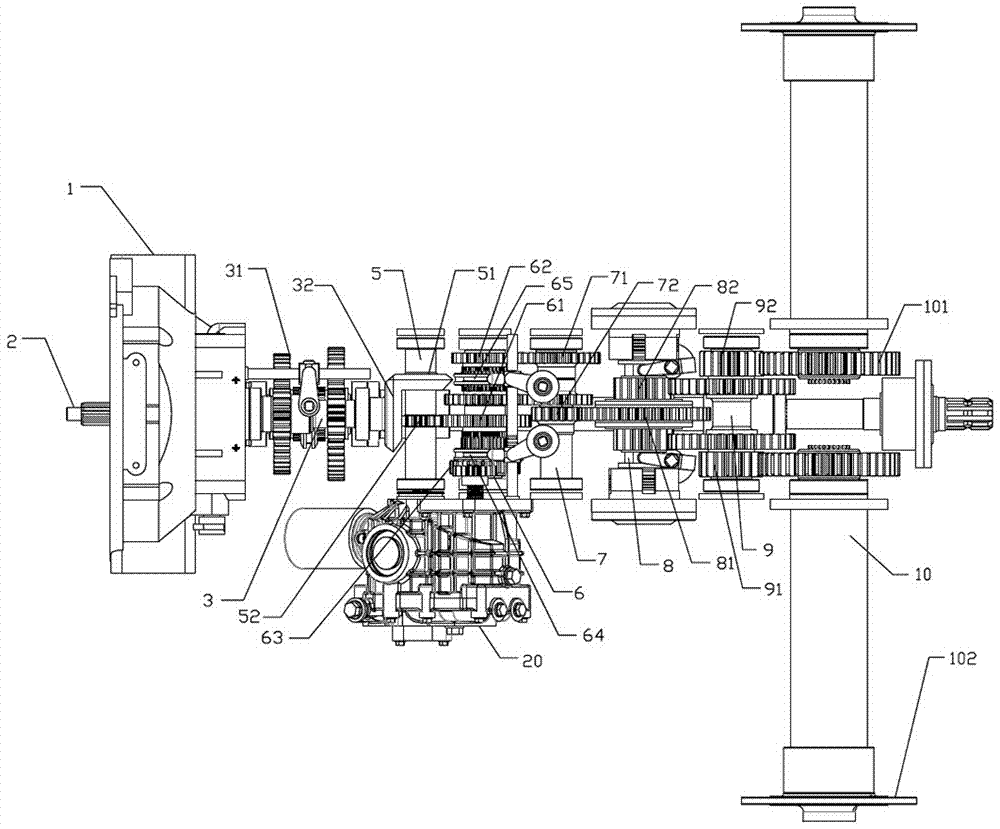

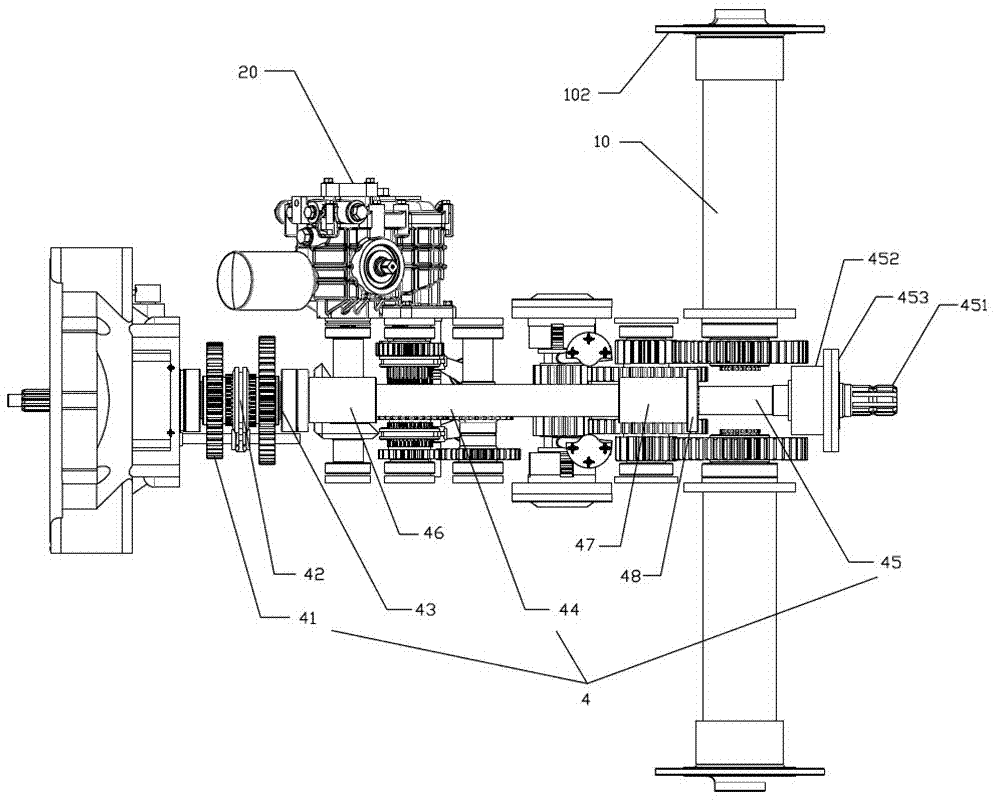

[0039] See figure 1 , figure 2 , a power system of a crawler tractor, including an engine, a clutch 1 and an input shaft 2, the clutch 1 is in the form of a pull rod release fork. The power system also includes a power split mechanism, a power output mechanism, and a driving wheel travel mechanism; the power split mechanism includes a power split shaft 3 connected to the input shaft 2, a power output driving gear 31 located on the power split shaft 3, and an HST power input drive. Gear 32; the power output driving gear 31 is a spur gear, and the power output driving gear 31 is provided with two, which are divided into a high-speed gear and a low-speed gear, and the HST power input driving gear 32 is a bevel gear;

[0040] The power output mechanism includes an output shaft 4 that is arranged in sections and is connected to two adjacent stages of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com