Method for treating and recycling sulfuric acid process titanium dioxide effluent

A technology of drainage treatment and sulfuric acid method, which is applied in natural water treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of low water dispersibility of titanium dioxide and discount of pigment application performance, and achieve qualified quality and treatment cost. Low, good operating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

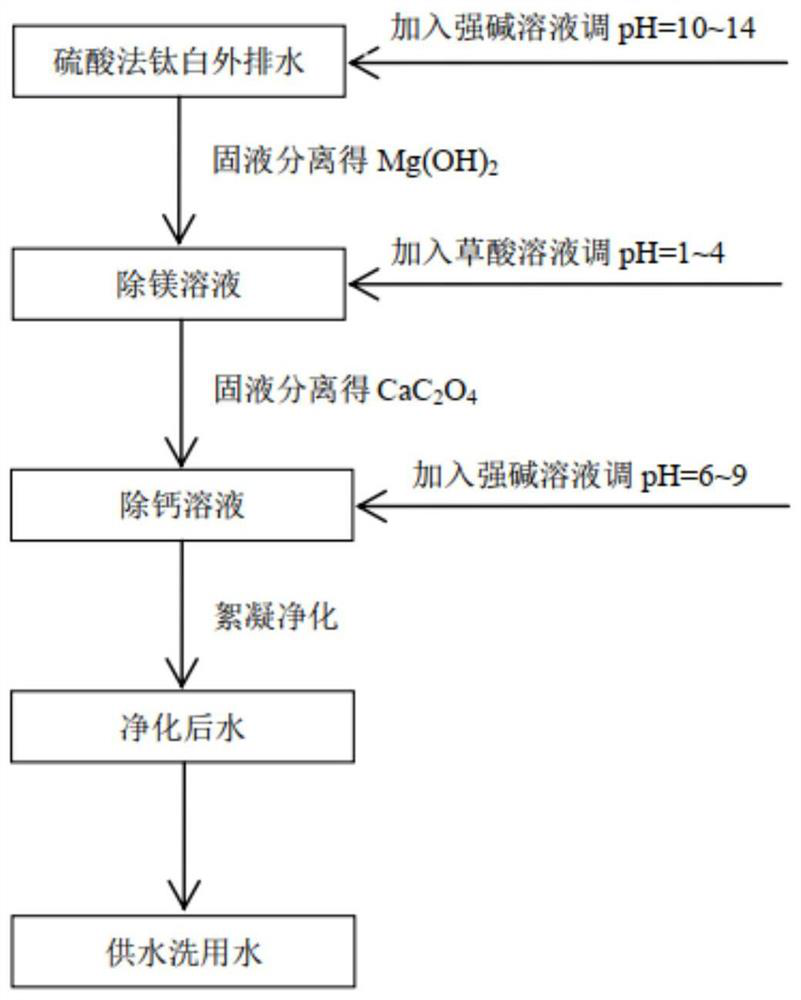

[0031] A method for treating and recycling titanium dioxide external wastewater by sulfuric acid process, comprising the following steps:

[0032] Take sulfuric acid process titanium dioxide external drainage, its index: pH=7, Mg 2+ = 160 mg / l, Ca 2+ = 550 mg / l, SS = 15 mg / l;

[0033]While blowing air, turn on the mechanical stirring, pump the external drainage of sulfuric acid titanium dioxide into the reaction tank, add KOH solution, adjust to pH = 11, stir for 30 minutes, and separate the solid and liquid through the diaphragm filter press to obtain the first The filtrate and the first solid, the first solid being Mg(OH) 2 ; After testing, magnesium ion content Mg in the first filtrate 2+ = 8mg / l;

[0034] While blowing air, turn on mechanical stirring, pump the first filtrate into the reaction tank, add oxalic acid solution, adjust to pH = 2, stir for 30 minutes, and separate the solid and liquid through a diaphragm filter press to obtain the second filtrate and the se...

Embodiment 2

[0043] A method for treating and recycling titanium dioxide external wastewater by sulfuric acid process, comprising the following steps:

[0044] Take sulfuric acid process titanium dioxide external drainage, its index: pH=7.5, Mg 2+ = 170 mg / l, Ca 2+ = 560 mg / l, SS = 18 mg / l;

[0045] While blowing air, turn on the mechanical stirring, pump the external drainage of sulfuric acid titanium dioxide into the reaction tank, add KOH solution, adjust to pH = 12.5, stir for 30 minutes, and separate the solid and liquid through the diaphragm filter press to obtain the first The filtrate and the first solid, the first solid being Mg(OH) 2 ; After testing, magnesium ion content Mg in the first filtrate 2+ = 5mg / l;

[0046] While blowing air, turn on mechanical stirring, pump the first filtrate into the reaction tank, add oxalic acid solution, adjust to pH = 1.5, stir for 30 minutes, and separate the solid and liquid through a diaphragm filter press to obtain the second filtrate and...

Embodiment 3

[0055] A method for treating and recycling titanium dioxide external wastewater by sulfuric acid process, comprising the following steps:

[0056] Take sulfuric acid process titanium dioxide external drainage, its index: pH=8.5, Mg 2+ = 165 mg / l, Ca 2+ = 580 mg / l, SS = 16 mg / l;

[0057] While blowing air, turn on the mechanical stirring, pump the external drainage of sulfuric acid titanium dioxide into the reaction tank, add KOH solution, adjust to pH = 11.5, stir for 30 minutes, and separate the solid and liquid through the diaphragm filter press to obtain the first The filtrate and the first solid, the first solid being Mg(OH) 2 ; After testing, magnesium ion content Mg in the first filtrate 2+ = 7mg / l;

[0058] While blowing air, turn on the mechanical stirring, pump the first filtrate into the reaction tank, add an oxalic acid solution with an oxalic acid content ≥ 99%, adjust to pH=1.8, stir for 30 minutes, and separate the solid and liquid through a membrane filter p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com