Solenoid valve

A solenoid valve and valve port technology, applied in the field of solenoid valves, can solve problems such as increased travel of the moving iron core, poor valve opening ability, and reduced suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

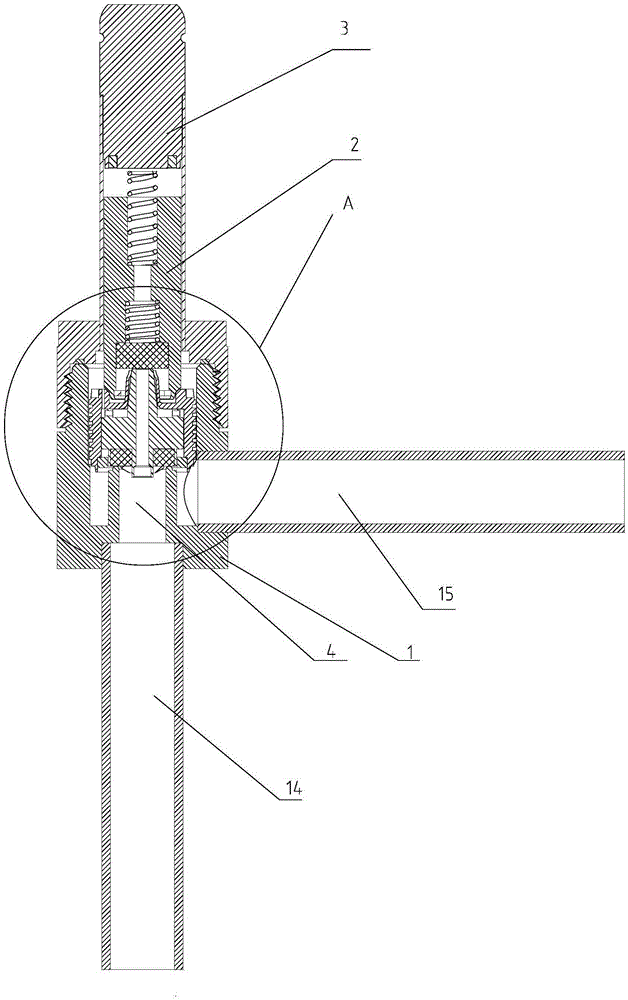

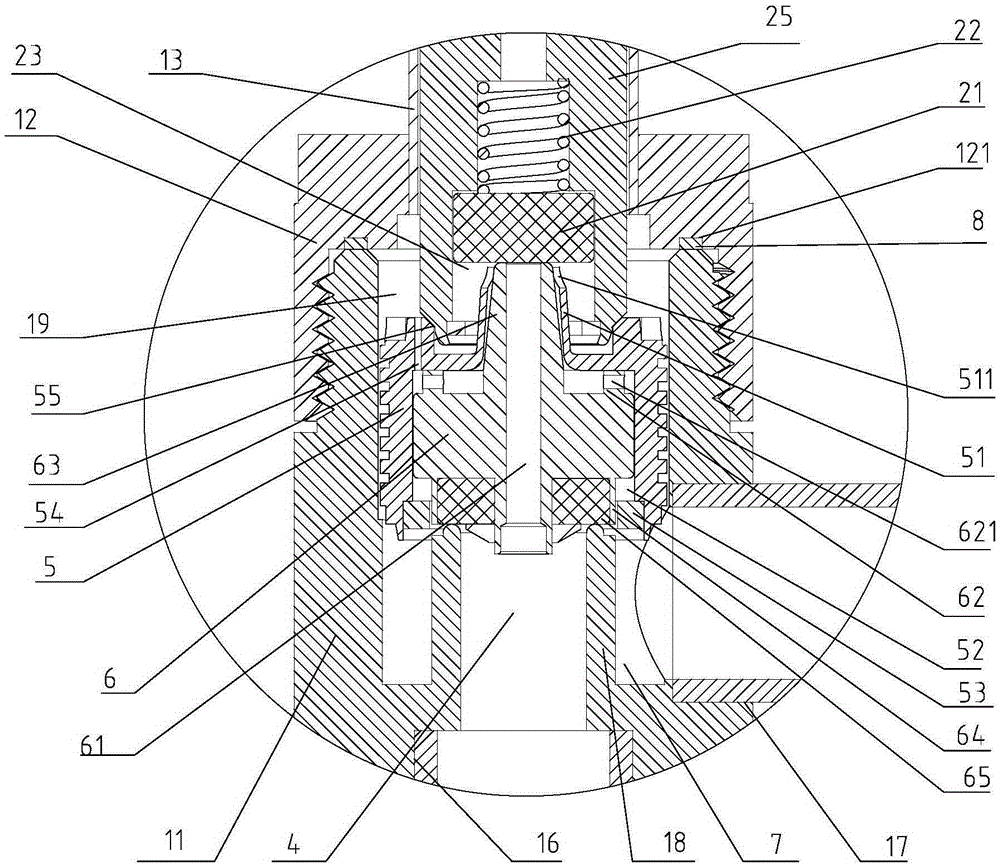

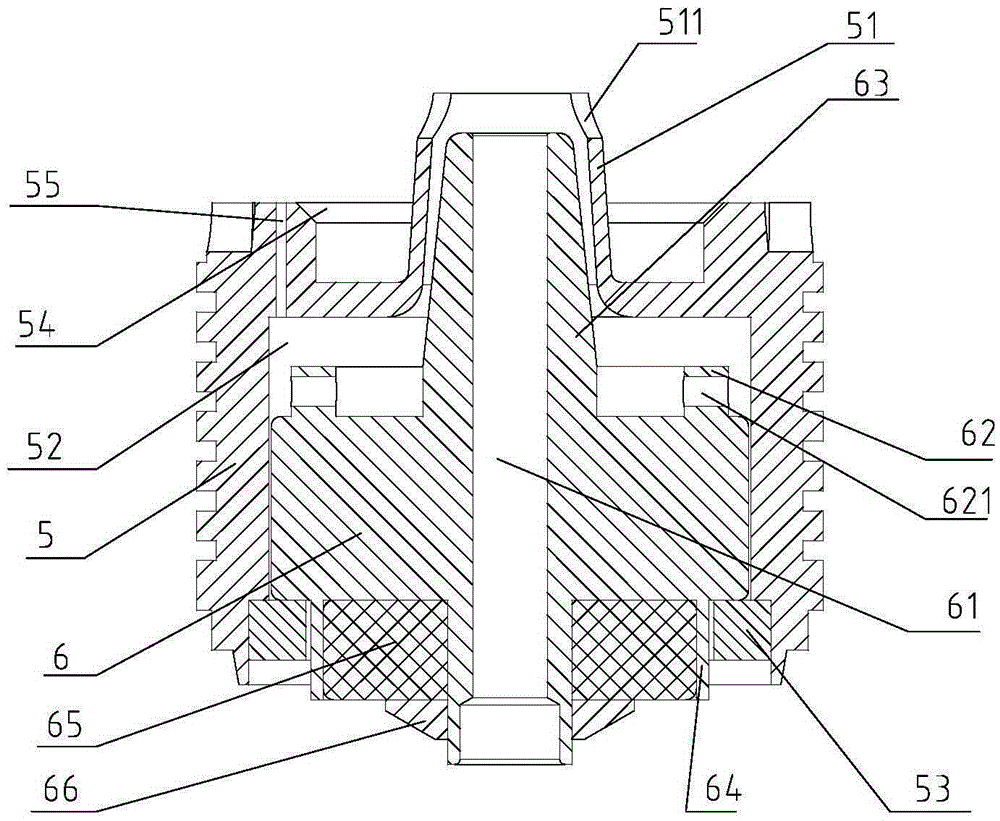

[0033] refer to figure 1 and figure 2 , shows a solenoid valve, including valve body 1, valve body 1 is provided with valve port 4, medium inlet 17 and medium outlet 16, static iron core 3, moving iron core 2 and piston assembly are installed in valve body 1 , the electromagnetic force of the static iron core 3 drives the moving iron core 2 to move, the piston assembly includes a top block 5 and a piston 6, the top block 5 is located between the moving iron core 2 and the valve port 4, and the piston 6 is slidably connected in the top block 5, The piston 6 is provided with a communication hole 61 that leads to the upper space and the lower space of the top block 5. The piston 6 is used to close the valve port 4, and in this state, there is a communication hole between the top block 5 and the valve body 1 that communicates with the medium inlet 17. The cavity 7, the fluid of the medium inlet 17 enters the cavity 7, and a high-pressure area is formed in the cavity 7, and the f...

Embodiment 2

[0044] refer to Figure 7 As shown, a solenoid valve includes a valve body 1, which is provided with a valve port 4, a medium inlet and a medium outlet, and a static iron core, a moving iron core 2 and a piston assembly are installed in the valve body 1, and the static iron core The electromagnetic force drives the moving iron core 2 to move. The piston assembly includes a top block 5 and a piston 6. The top block 5 is located between the moving iron core 2 and the valve port 4. The piston 6 is slidably connected in the top block 5. The piston 6 is provided with The communication hole 61 that connects the upper space and the lower space of the top block 5, the piston 6 is used to close the valve port 4, and in this state, a cavity 7 communicating with the medium inlet is formed between the top block 5 and the valve body 1. The pressure in 7 and the action of the moving iron core 2 drive the top block 5 to move relative to the valve port 4, and the piston 6 moves with the top b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com