Control valve assembly

A technology for controlling valves and components, applied in engine components, machines/engines, charging systems, etc., can solve the problems of large spring force of valve components, increased cost of solenoid valves, and increased driving requirements, and achieve volume reduction and driving requirements. The effect of reducing, reducing the electromagnetic force requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

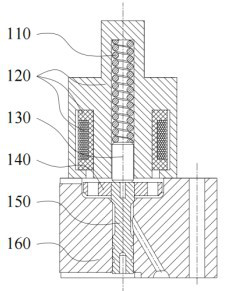

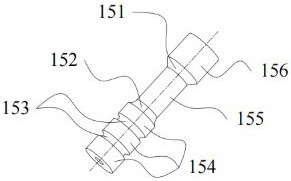

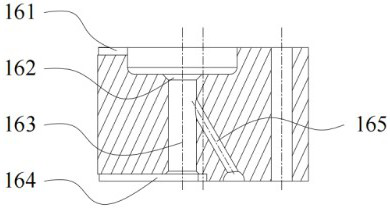

[0018] like Figure 1 to Figure 4 As shown, a control valve assembly adopts a new structural design. When in use, the hydraulic pressure generated by the high-pressure fluid on the lower surface is opposite to the hydraulic pressure on the upper surface, and the two hydraulic forces cancel each other out. Therefore, only a small The upper spring force of the valve stem can maintain the cone surface on the seat surface, the corresponding electromagnetic force requirement is reduced, the cost of the solenoid valve is reduced, the size is reduced, the driving requirement is reduced, the overall durability is stronger during use, and the service life is longer , the use safety is more reliable, and it can have more reliable use stability. It includes a valve body 160, the valve body 160 is provided with a valve body middle hole 163, the upper end of the valve body middle hole 163 is a seat surface 162, and the lower end of the valve body 160 is connected to the bottom of the valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com