Full-automatic snowmaker device

A fully automatic, snow-making technology, applied in the field of snow-making machines, can solve the problems of low snow-making efficiency and inability to provide continuous snow-making machines, and achieve the effects of increasing snow-making density, improving snow-making efficiency, and setting reasonable settings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

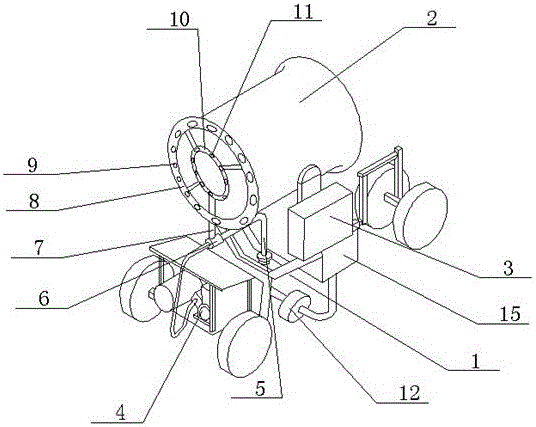

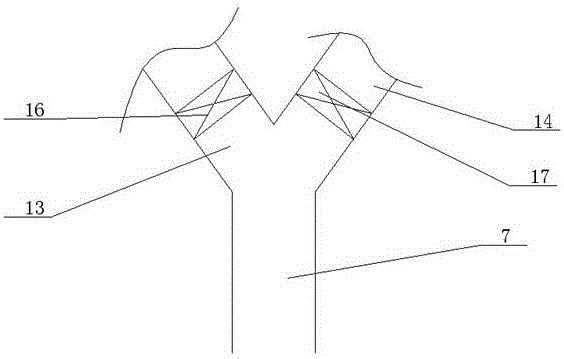

[0016] see figure 1 As shown in and , the technical solution adopted in this specific embodiment is: it includes frame 1, blower 2, electric control box 3, air compressor 4, water pipe 5, air-water mixer 6, and air-water mixer goes out mist Pipe 7, outer spray pipe 8, outer nozzle 9, the top of frame 1 is provided with blower 2 and electric control box 3 respectively, and one end of blower 2 is provided with outer spray pipe 8, is connected with several on the outer spray pipe 8 An outer nozzle 9, the frame 1 is provided with an air compressor 4, the air compressor 4 is connected with the air-water mixer 6 through a pipeline, and the other end of the air-water mixer 6 is connected with a water pipe 5, the air-water mixer 6 The upper part is provided with the mist outlet pipe 7 of the gas-water mixer; 8 connections, the inner circle mist outlet pipe 14 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com