Large-liquid-amount constant-pressure displacement indoor physical simulation experiment method

A technology of physical simulation and experimental method, which is applied in the field of large liquid volume and constant pressure displacement indoor physical simulation experiment and core displacement simulation experiment field, which can solve the problems of easy vibration, increased work intensity, large error, etc. sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

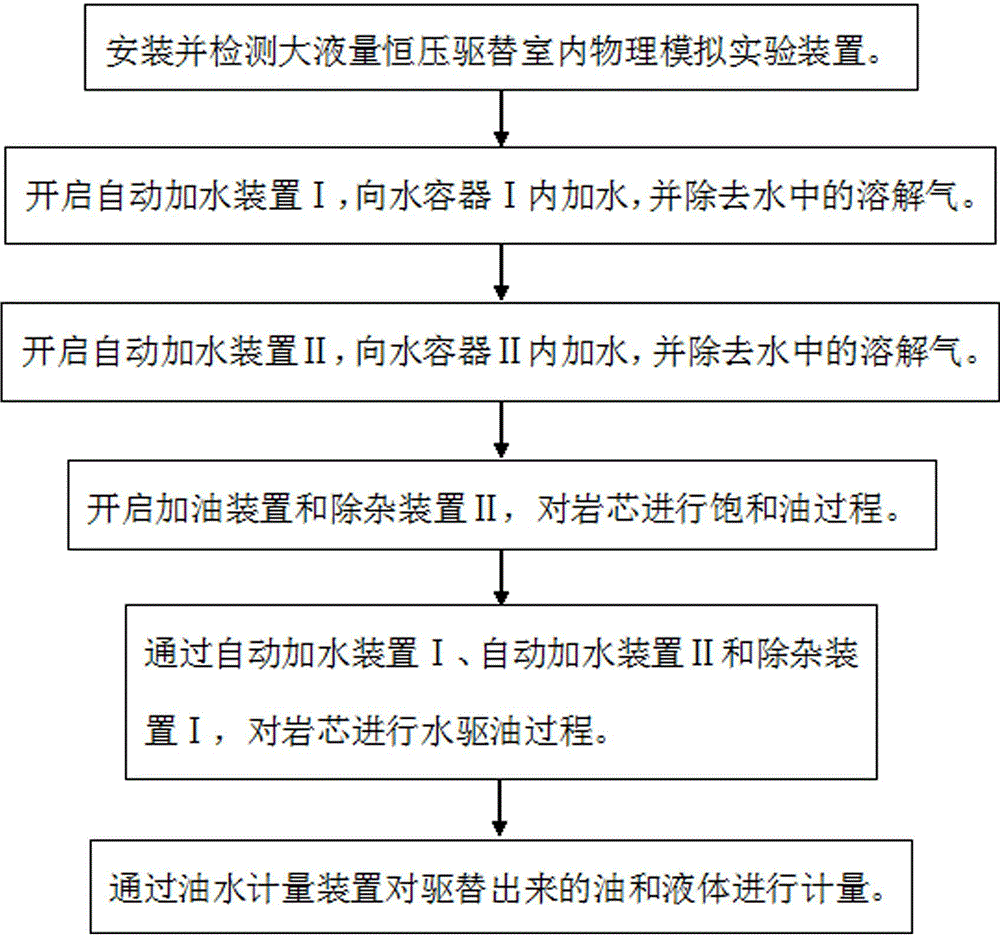

[0092] like figure 1 As shown, according to an embodiment of the large-volume constant-pressure displacement indoor physical simulation experimental method of the present invention, it includes the following steps in sequence:

[0093] Step 1: Install and test the indoor physical simulation experimental device for large liquid volume and constant pressure displacement;

[0094] Step 2: Turn on the automatic water adding device I, add water to the water container I, and remove the dissolved gas in the water;

[0095] Step 3: Turn on the automatic water adding device II, add water to the water container II, and remove the dissolved gas in the water;

[0096] Step 4: Turn on the oil filling device and the impurity removal device II, and carry out the process of saturating the core with oil;

[0097] Step 5: The core is subjected to the water flooding process through the automatic water addition device I, the automatic water addition device II and the impurity removal device I; ...

Embodiment 2

[0144] According to another embodiment of the large-volume constant-pressure displacement indoor physical simulation experiment method of the present invention, its technological process, working principle, experimental device adopted, beneficial effects, etc. are all the same as those of the first embodiment, and the difference is: Figure 8 As shown, the large-volume constant-pressure displacement indoor physical simulation experimental device also includes an alarm device 7 . The alarm device is provided with a buzzer 71 and a plurality of alarm lights 72, and different alarm lights correspond to different alarm positions. When an abnormality or failure occurs in a certain part of the experimental device, the buzzer sends out an alarm signal, and at the same time with the alarm signal. The alarm light corresponding to the part flashes. Before the abnormal phenomenon or fault disappears, the buzzer sounds for 5s every 5 minutes, and the alarm light keeps flashing. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com