Baotou Steel belt-type pellet energy-saving furnace roof

A roasting furnace and furnace top technology, applied in the direction of the furnace crown/roof, can solve the problems of low pellet production and short service life, and achieve the effects of long service life, convenient local maintenance, and simple production and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

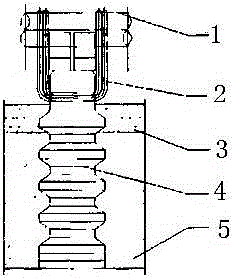

[0013] like figure 1 The roof of a steel-clad belt-type pellet energy-saving roasting furnace shown includes: a hanging pipe 1, a hanging piece 2, an insulation layer 3, an anchor brick 4, and a furnace roof pouring material 5; the hanging pipe 1 is embedded horizontally In hanger 2.

[0014] The thermal insulation layer 3 is outside the topmost anchor brick 4 .

[0015] The anchor brick 4 is the joint between the layers.

[0016] The furnace top pouring material 5 is connected with the insulation layer 3 .

[0017] The working principle of the roof of Baotou steel belt-type pellet energy-saving roasting furnace of the present invention is to prolong the service life of the furnace roof, reduce the maintenance time, increase the output of pellets, and at the same time to better control the roasting temperature of each stage of pellets , Added 6 temperature measuring points on the top of the furnace. Based on the above reasons, the roof-hanging brick masonry was changed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com