High-back-pressure condenser

A condenser and high back pressure technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problem that the condenser water chamber does not meet the requirements of high back pressure water chamber, and the energy saving effect of the condenser is not obvious , corrugated expansion joints are easy to damage and other problems, and achieve obvious energy saving effect, low condensate supercooling degree and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] All the features disclosed in this specification, except mutually exclusive features and / or steps, can be combined in any way.

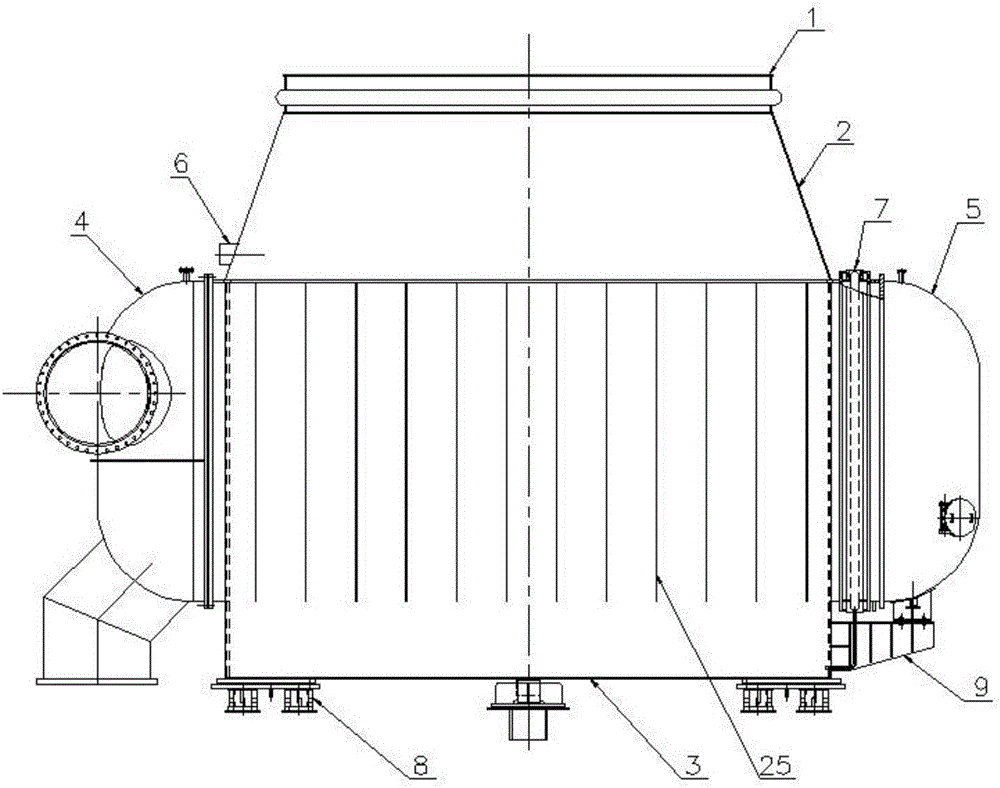

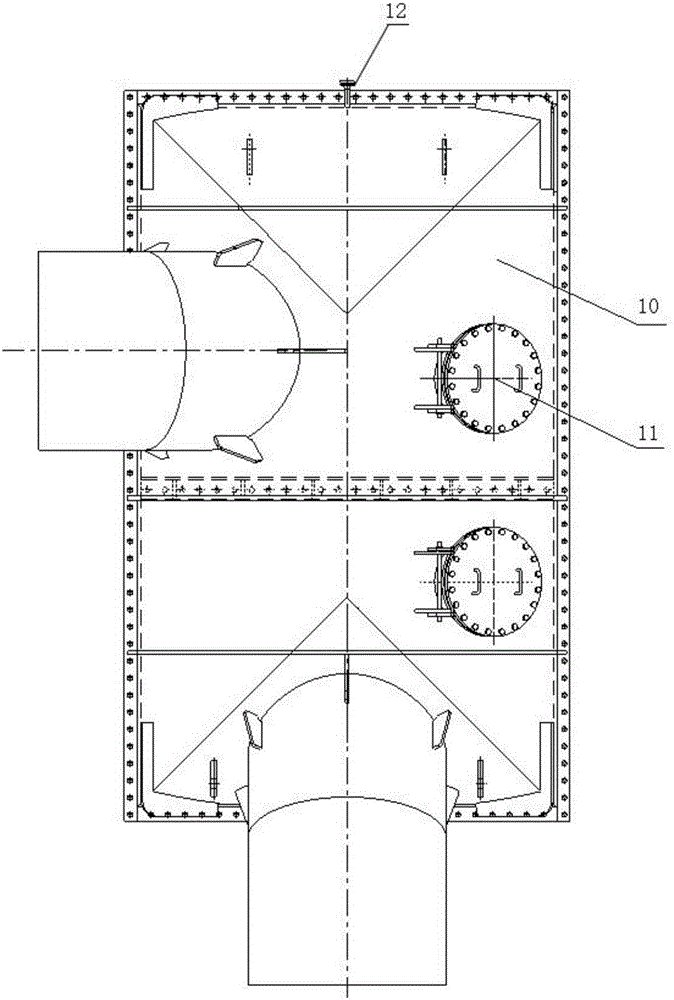

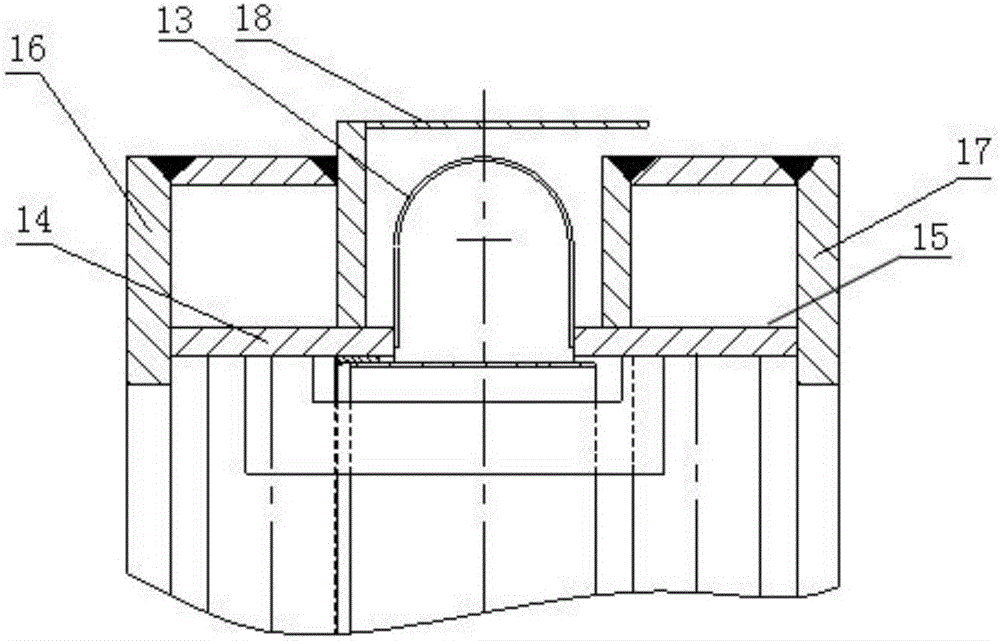

[0023] Combine below figure 1 , image 3 , Image 6 The present invention will be described in detail.

[0024] Such as figure 1 As shown, a high back pressure condenser includes a condenser shell 3 and a condenser throat 2 connected to the condenser shell 3, and the condenser shell 3 is connected to the front end of the condenser The plate tube and the tube plate at the rear end of the condenser, the middle plate tube 25 is fixed in the condenser shell, and the feature is that the condenser throat 2 is connected with a wave expansion joint 7 with a protection device, and the front end of the condenser There is a full-arc front water chamber 4 on the plate tube, and a full-arc rear water chamber 5 is connected to the tube plate at the rear end of the condenser. The waveform between the full-arc rear water chamber 5 and the condenser shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com