Real-time ultrasonic scanning device used during rock triaxial compression

A technology of three-axis compression and scanning device, which is applied in measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the problem of cracks not being able to be located, achieve reliable test methods, and prevent disasters and accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

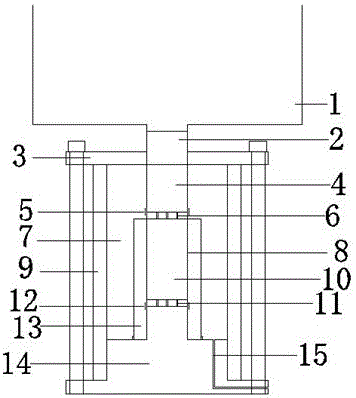

[0018] The technical solution of the present invention will be further specifically described below by means of the examples and in conjunction with the accompanying drawings. The permeable backing plate 6, the lower permeable backing plate 11, and the lower clamp 12 are formed. The test chamber 10 is placed on the top round platform of the bottom cover 14, fixed on the top round platform by the lower clamp 12, and the rock sample is placed in the test chamber 10. The upper water-permeable backing plate 6 and the lower water-permeable backing plate 11 make the pressure of the rock sample uniform in the test chamber and facilitate the pore pressure test of the rock sample.

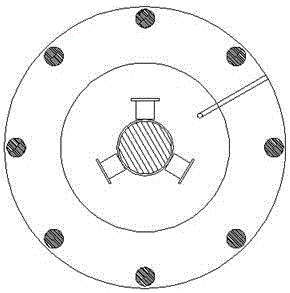

[0019] The three sets of ultrasonic scanning probes 13 in the device are placed on the middle round table of the bottom cover 14 at an angle of 120° to each other, and are closely attached to the outer wall of the test chamber 10, and are fixed by the yokes on the middle round table of the bottom cover 14. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com