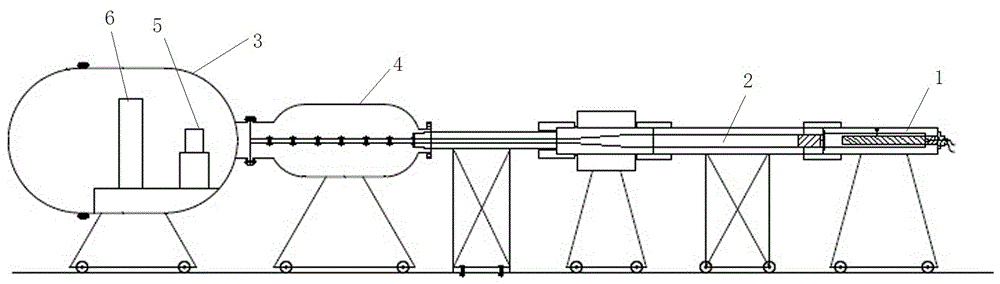

Multifunctional high-speed impact experimental equipment

A kind of experimental equipment and multi-functional technology, which can be used in impact testing, measuring devices, instruments, etc., can solve the problems of inability to achieve target impact, single function, and cannot be used to study structural damage, and achieve good practicability and convenience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

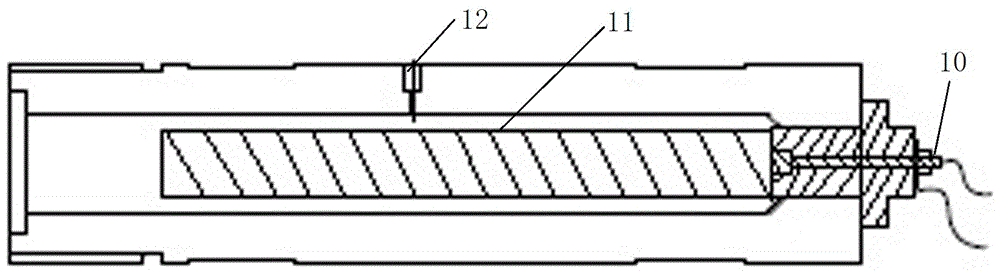

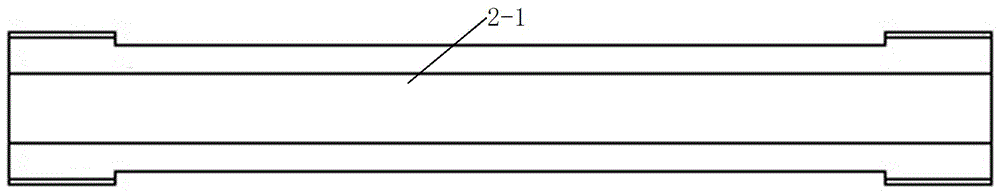

[0030] Embodiment: A kind of multi-functional high-speed impact experiment equipment, comprises launching device 1, gun barrel 2 and target chamber 3, and launching device 1 is connected with gun barrel 2, and gun barrel 2 is connected with target chamber 3 through projectile and bullet support separating device 4 , the target chamber 3 is provided with a velocity measuring device 5 and a target board loading device 6, the target board loading device 6 includes a horizontal stretching servo actuator 6-1, a vertical stretching servo actuator 6-2, a rack 6-3, the horizontal adjustment mechanism 6-4, the vertical adjustment mechanism 6-5, the rotation mechanism 6-6, the wheel 6-7 and the hydraulic pressure source 6-8, and the hydraulic pressure source 6-8 is stretched horizontally around The servo actuator 6-1, the vertical stretch servo actuator 6-2, the horizontal adjustment mechanism 6-4 and the vertical adjustment mechanism 6-5 are arranged on the frame 6-3, and the vertical a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com