Auxiliary plug board for circuit breaker test

A circuit breaker and plug-in technology, applied in the field of circuit breaker test auxiliary plug-in panels, can solve problems such as hidden dangers of operation safety, overhaul time, human resources, occupation, etc., so as to reduce labor and time costs, reduce the number of operators, and reduce The effect of operational risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

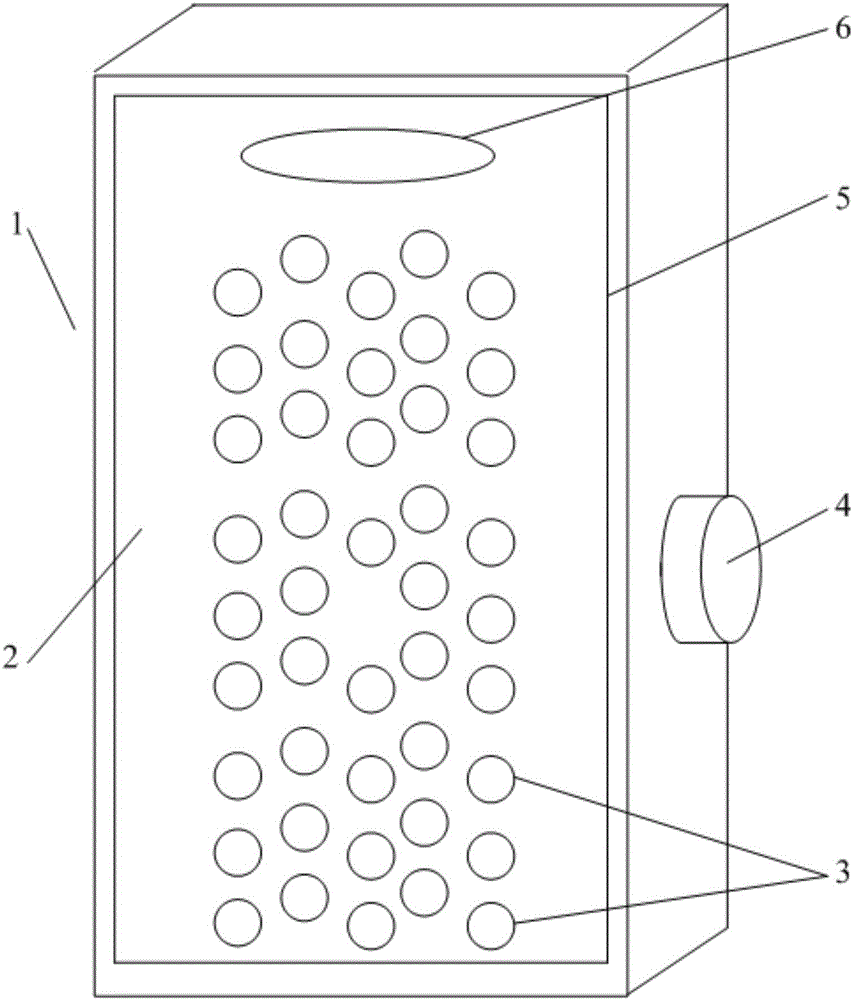

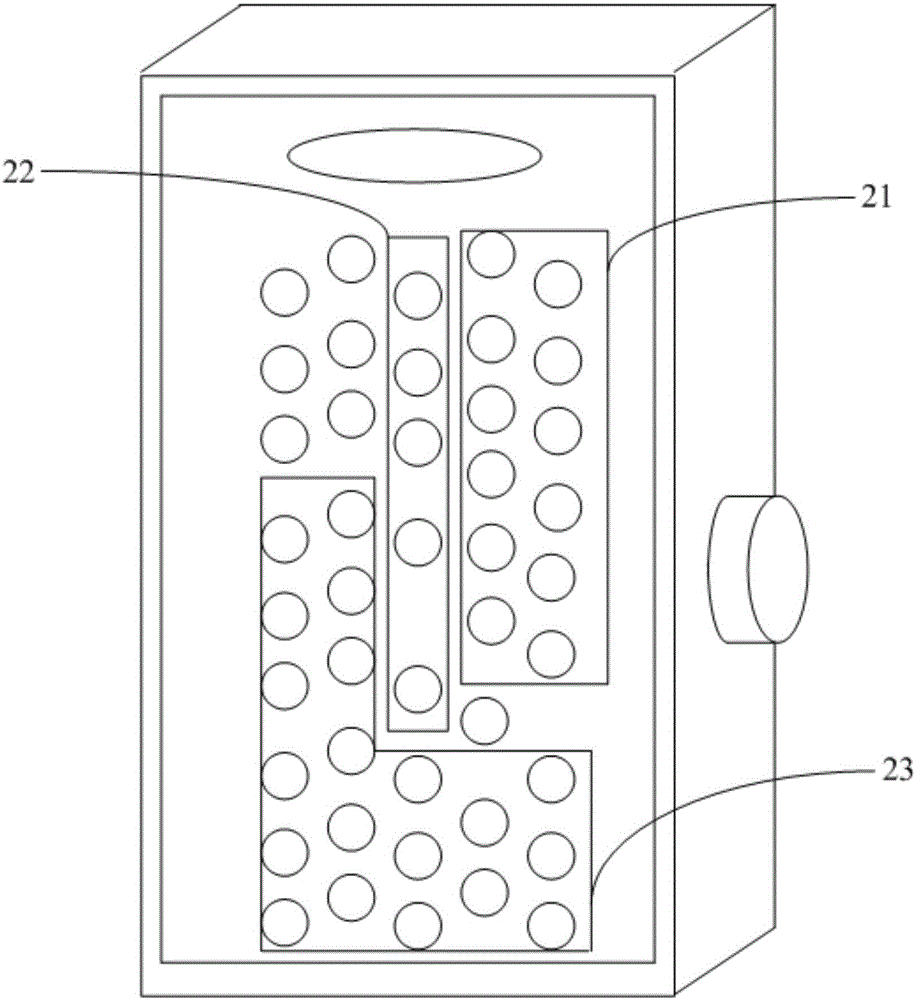

[0027] The invention provides an auxiliary plug board for circuit breaker testing, the auxiliary plug board is used to connect aviation plugs, and the auxiliary plug board, such as figure 1 As shown, it includes: a board body, a contact plane is provided on the board body, and a wiring hole corresponding to the pin on the aviation plug is provided on the contact plane. The side is provided with a fixed column that is snapped into the fixed bolt on the aviation plug;

[0028] A waterproof protrusion is provided on the edge of the contact plane on the board, and the waterproof protrusion protrudes a first height relative to the contact plane;

[0029] There is also a reserved area without wiring holes on the contact plane, and an infrared sensing module is arranged in the reserved area, and the infrared sensing module is connected to the output end of the auxiliary plug-in board.

[0030] In practice, the auxiliary board is connected with the aviation plug. A board body 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com