Fiber/CNT(carbon nano tube)/MgFe2O4 three-dimensional recyclable efficient catalytic material, as well as preparation and application thereof

A technology of carbon nanotubes and catalytic materials, which is applied in the field of catalyst materials and their preparation and application, can solve problems such as unfavorable sustainable development, and achieve the effects of recycling and reuse, increasing the contact interface, and accelerating the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

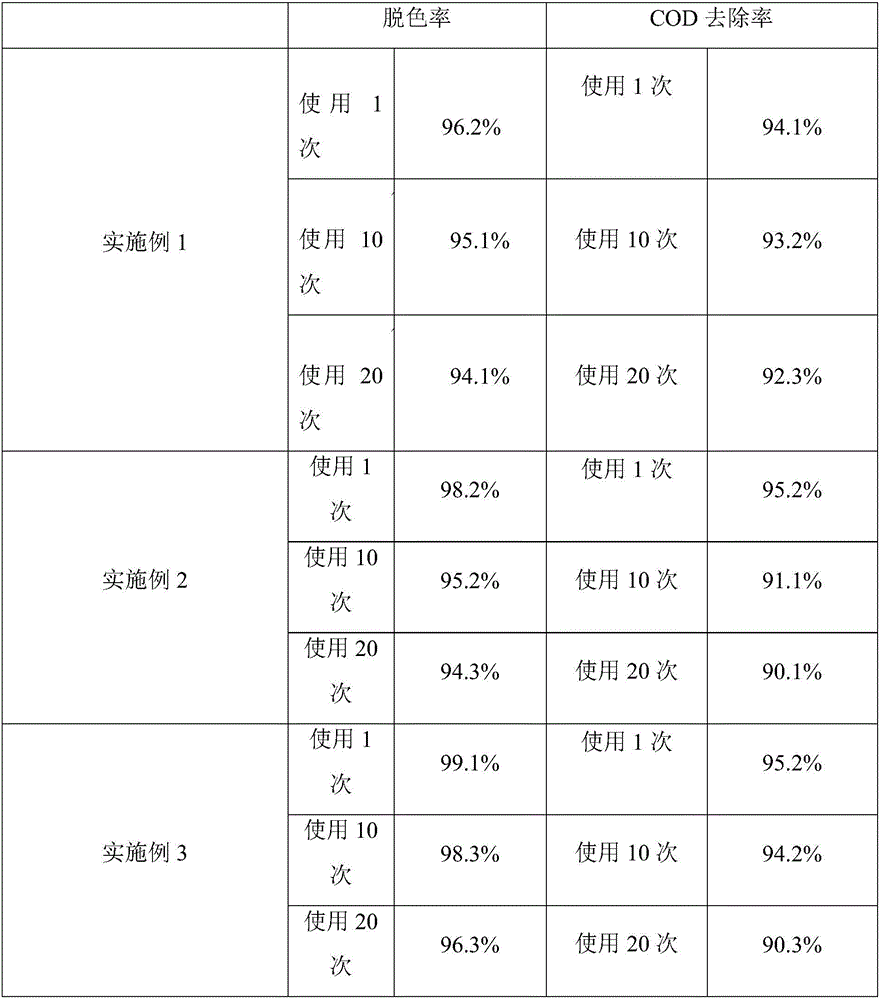

Examples

Embodiment 1

[0031] (1) Add 150mg CNTs to 30mL of mass percent concentration 30% FeCl 2 Solution, adjust pH=3, then add 30mL H 2 o 2 , sonicate at room temperature for 0.5 h, magnetically stir at room temperature for 6 h, add 500 mL of water, wash with water until neutral, and filter with suction. Vacuum drying at 60°C for 24h to obtain product a;

[0032] Under the condition of blowing nitrogen, disperse 1.5g of product a in 100mL DMF in a dry three-necked flask, cool in an ice-water bath, add 300mg of NaH at 0°C, and continue stirring for 20min. Then gradually raise the temperature to 85°C, add 2mL of 1-perfluorohexyl iodide dropwise, ultrasonically react for 18h, add a small amount of water to quench the reaction, and wash by centrifugation with DMF, ethanol and water successively. The obtained black granular product b was dried in a vacuum oven at 50°C for 96h;

[0033] Disperse 1g of black product b in 50mL of water, add 300mg of NaOH, ultrasonically disperse for 0.5h, disperse 1g...

Embodiment 2

[0039] (1) Add 175mg CNTs to 35mL of 30% FeCl 2 In the solution, adjust the pH to 3, then add 35mL H2O2, sonicate at room temperature for 1.5h, magnetically stir at room temperature for 87h, add 500mL of water, wash with water until neutral, and filter with suction. Vacuum drying at 60°C for 24h to obtain product a;

[0040] Under the condition of blowing nitrogen, disperse 2.5g of product a in 150mL DMF in a dry three-necked flask, cool in an ice-water bath, add 411mg of NaH at 0°C, and continue stirring for 30min. Then gradually raise the temperature to 88°C, add 2.5mL of 1-perfluorohexyl iodide dropwise, and react perfluorohexyl iodide with ultrasound for 20 hours. A small amount of water was added to quench the reaction, followed by centrifugation washing with DMF, ethanol and water. The obtained black granular product b was dried in a vacuum oven at 50°C for 96h;

[0041] Disperse 1.5g of product b in 50mL of water, add 438mg of NaOH, ultrasonically disperse for 1h, di...

Embodiment 3

[0047] (1) Add 200mg CNTs to 40mL of 30% FeCl 2 In the solution, adjust pH=3, then add 40mL H2O2, ultrasonicate at room temperature for 2h, magnetically stir at room temperature for 8h, add 500mL of water, wash with water until neutral, and filter with suction. Vacuum drying at 60°C for 24h to obtain product a;

[0048] Under the condition of blowing nitrogen, disperse 3g of product a in 200mL DMF in a dry three-necked flask, cool in an ice-water bath, add 522mg of NaH at 0°C, and continue stirring for 30min. Then gradually raise the temperature to 90°C, add 3mL of 1-perfluorohexyl iodide dropwise, and react perfluorohexyl iodide with ultrasound for 24 hours. A small amount of water was added to quench the reaction, followed by centrifugation washing with DMF, ethanol and water. The obtained black granular product b was dried in a vacuum oven at 50°C for 96h;

[0049] Disperse 2g of product b in 50mL of water, add 438mg of NaOH, ultrasonically disperse for 1h, disperse 2g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com