Rolling contact electric method real-time advance detection mounting device and method for tbm

A technology of advanced detection and rolling contact, applied in measurement devices, electric/magnetic exploration, radio wave measurement systems, etc., can solve problems such as affecting advanced geological detection, destroying electrodes and pushing devices, and easily damaged cutter disk electrodes, etc. To achieve the effect of real-time automatic detection, overcome the extremely narrow space, and improve the ability of advanced detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the following description is only for explaining the present invention, not limiting its content.

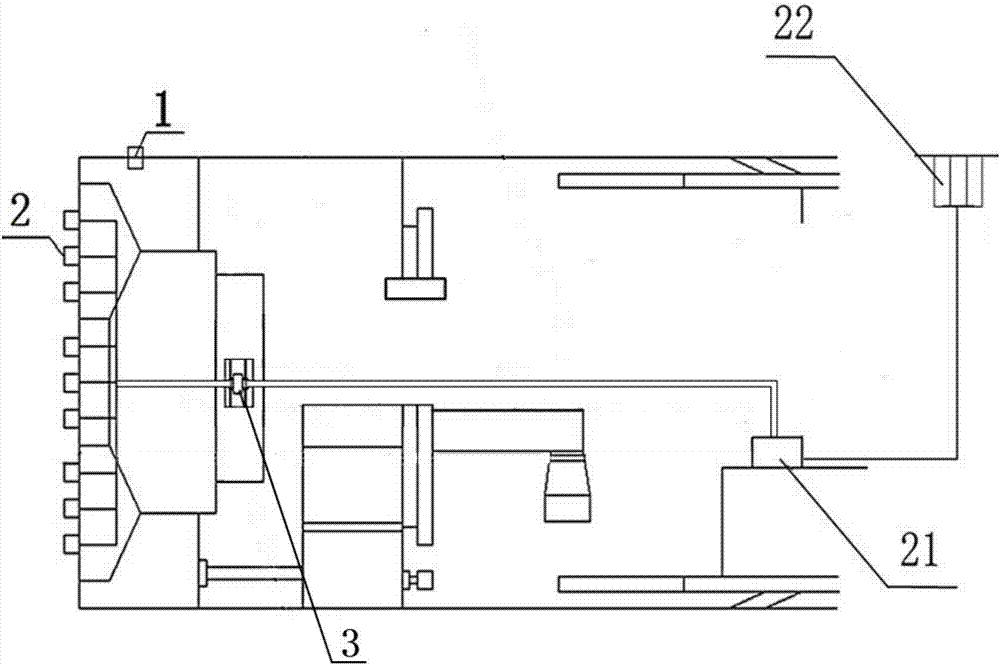

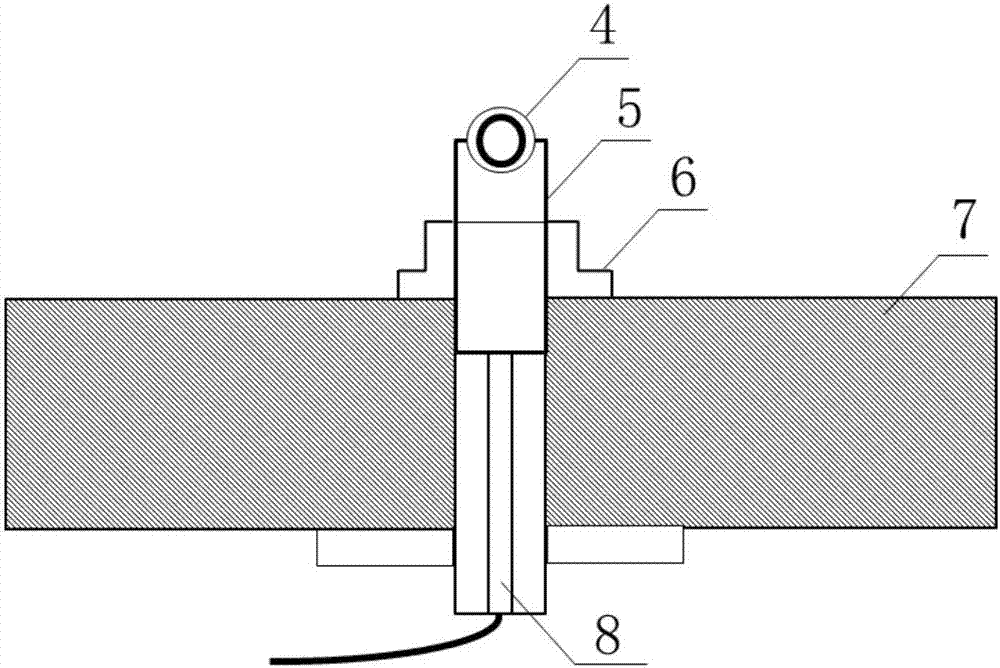

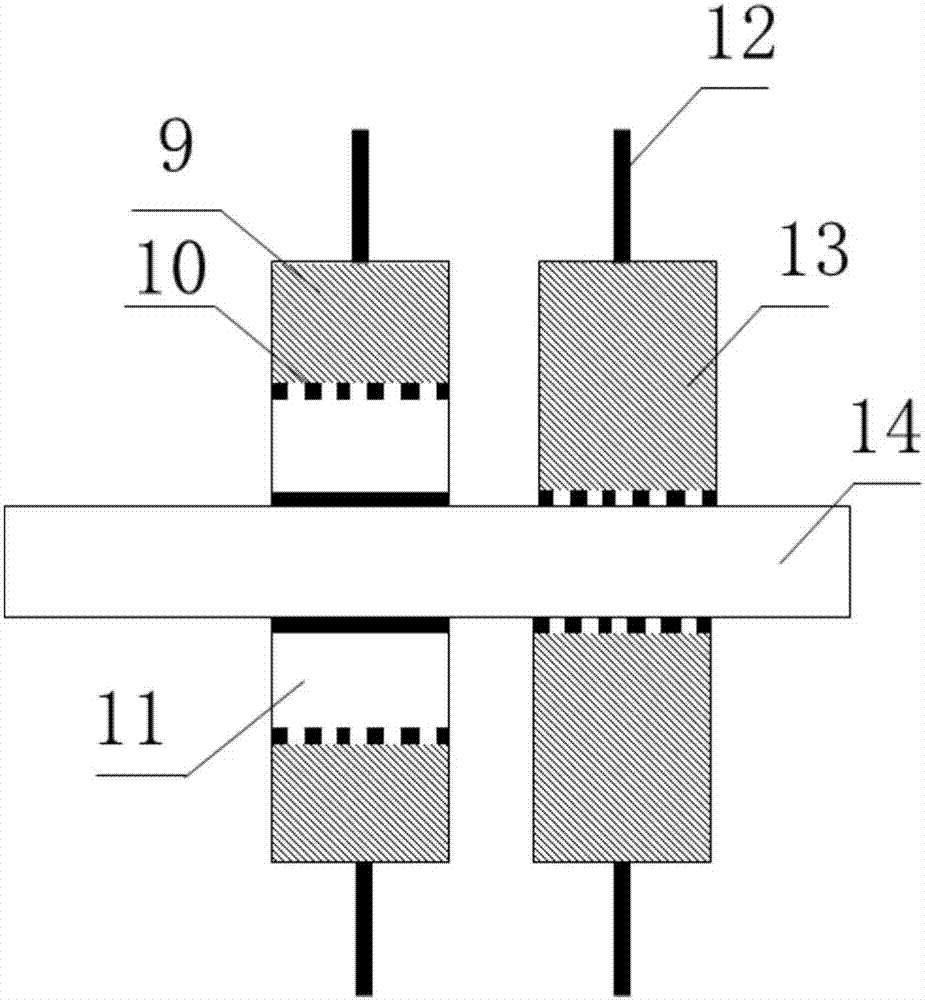

[0041] Such as figure 1 As shown, a rolling contact electric method real-time advanced detection device mounted on a TBM includes: rolling hydraulic electrodes, rotary wiring equipment 3, combined pipeline 23 and fixed electrode 22; rolling hydraulic electrodes are connected to the rotary wiring through the combined pipeline 23 The device 3 completes the electrical signal and oil pipeline connection between the cutter head and the TBM main body, and the host system 21 is connected to the rotary wiring device 3 and the fixed electrode 22 respectively.

[0042] The electrical connection realizes the power supply and measurement path for the rolling hydraulic electrode, the oil connection realizes the pushing and recovery of the rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com