A manufacturing process for ultra-narrow display frame

A production process and display technology, applied in the fields of instruments, nonlinear optics, optics, etc., can solve the problem of difficult to meet the requirements of reducing the ultra-narrow frame and frame, and achieve the effect of reducing display discontinuity, reducing size, and reducing space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

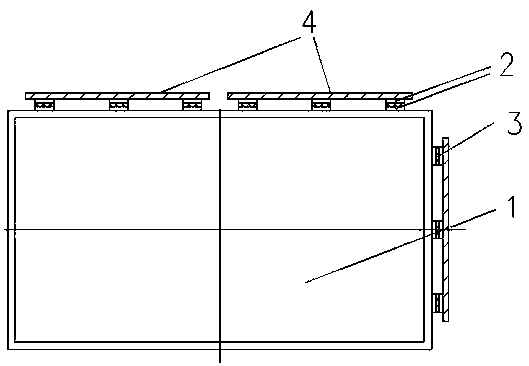

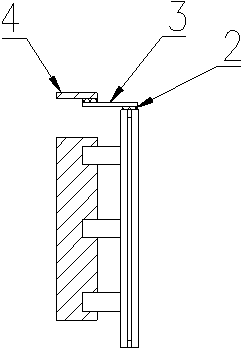

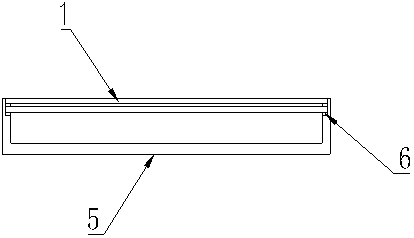

Image

Examples

Embodiment 1

[0029] 1) The upper layer of the display screen is the CF layer, the lower layer is the TFT layer, the liquid crystal conductive medium is coated in the middle, and the polarizer to be attached is printed on the display glass. A laser cutting device is used to cut the edge of the polarizer, the size of the polarizer to be bonded is cut to exceed the display screen by 2mm, the polarizer to be cut is bonded to the display screen, and then the laser is used to align the RGB corners. The polarizer is cut twice to make the size of the polarizer the same as the display screen.

[0030] The upper and lower sides of the display screen are the glass planes of the LCD display screen, and the rest are the sides of the LCD display screen.

[0031] 2) Plasma cleaning of the bonding surface requires the bonding surface to be grinded to make the finish Ra less than 0.32um, and the straightness and verticality meet the requirements of the display screen. The display screen can be rotated on the be...

Embodiment 2

[0039] 1) The upper layer of the display screen is the CF layer, the lower layer is the TFT layer, the liquid crystal conductive medium is coated in the middle, and the polarizer to be attached is printed on the display glass. A laser cutting device is used to cut the edge of the polarizer, the size of the polarizer to be bonded is cut to exceed the display screen by 2mm, the polarizer to be cut is bonded to the display screen, and then the laser is used to align the RGB corners. The polarizer is cut twice to shrink the polarizer by 0.15mm relative to the display screen.

[0040] The upper and lower sides of the LCD display screen are the glass planes of the display screen, and the rest are the sides of the LCD display screen.

[0041] 2) Plasma cleaning of the bonding surface requires the bonding surface to be grinded to make the finish Ra less than 0.32um, and the straightness and verticality meet the requirements of the display screen. The display screen can be rotated on the be...

Embodiment 3

[0049] 1) The upper layer of the display screen is the CF layer, the lower layer is the TFT layer, the liquid crystal conductive medium is coated in the middle, and the polarizer to be attached is printed on the display glass. A laser cutting device is used to cut the edge of the polarizer. The size of the polarizer to be bonded is cut by 3mm beyond the display screen. The polarizer to be cut is bonded to the display screen, and the polarizer is flush with or opposite to the display screen. The screen is retracted, and then the polarizer is cut twice with the laser based on the RGB corners to make it the same size as the screen.

[0050] The upper and lower sides of the LCD display screen are the glass planes of the display screen, and the rest are the sides of the LCD display screen.

[0051] 2) Plasma cleaning of the bonding surface requires the bonding surface to be grinded to make the finish Ra less than 0.32um, and the straightness and verticality meet the requirements of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com