Electric response infrared reflection device and preparation method thereof

A technology of infrared reflection and electrical response, applied in the field of liquid crystal devices and optics, can solve the problems of easy interference with navigation and communication systems, inability to meet people, and difficult to popularize coated glass on a large scale, so as to achieve the effect of adjusting the reflection band.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

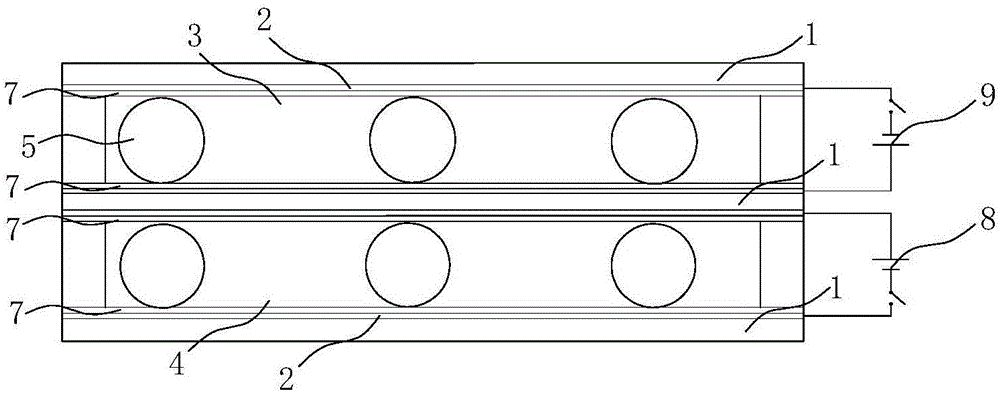

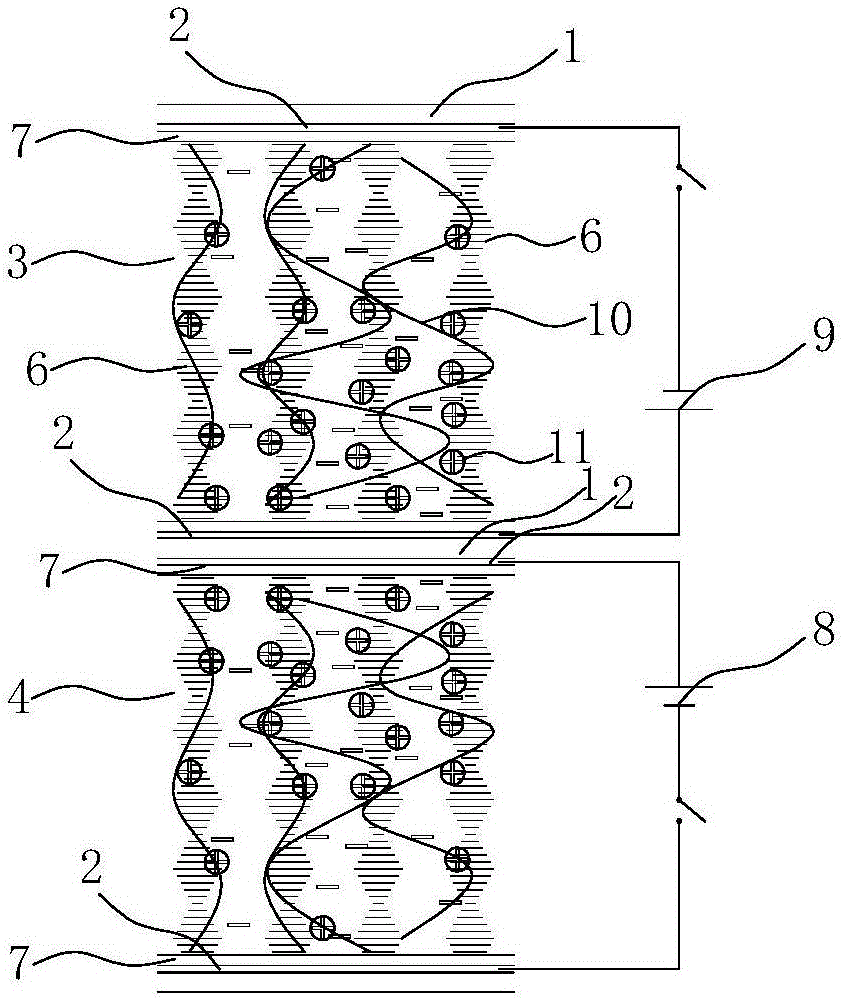

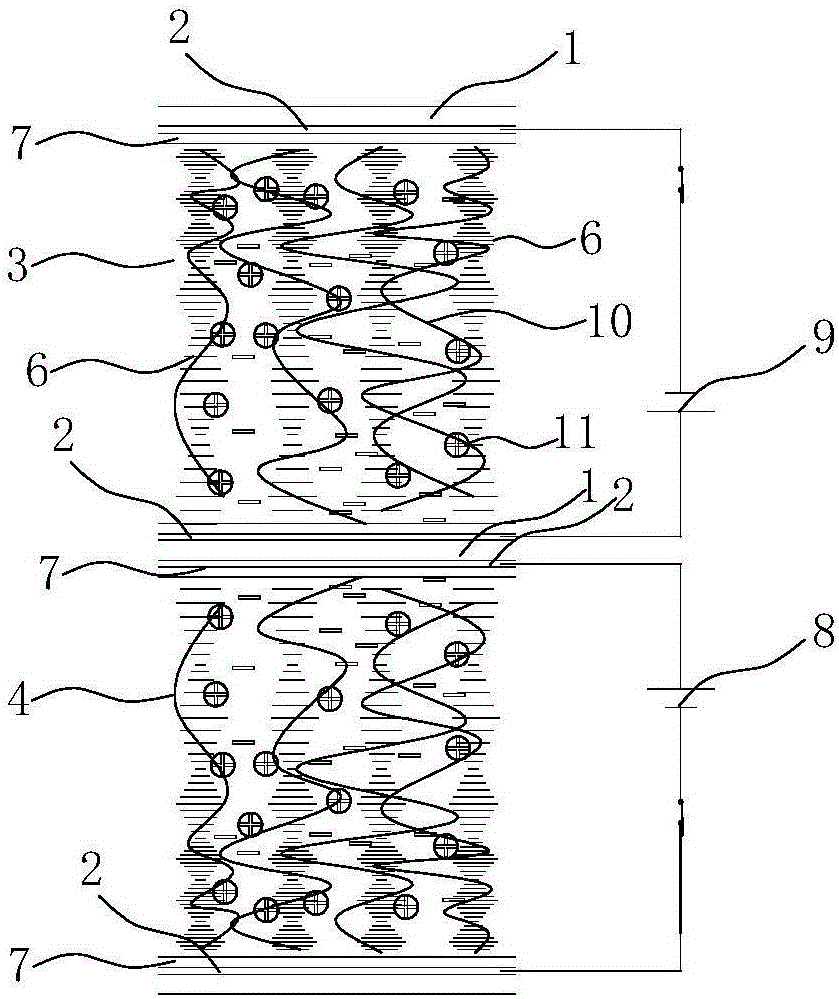

[0031] Three substrates are taken and cut, and a conductive layer is prepared on the surface of the substrate, and a layer of conductive layer is prepared on the upper and lower surfaces of one of the substrates, and the sides of the three light-transmitting conductive substrates with the conductive layer are facing each other, and then packed into liquid crystal cells. The liquid crystal cell has two adjustment areas; take 75-85 parts by mass of chiral nematic liquid crystal, 13-14.5 parts by mass of right-handed chiral dopant, 3-5 parts by mass of monomer and 0.5-1 mass part The photoinitiator of 30 parts is mixed, obtains mixed liquid crystal material A, gets the chiral nematic phase liquid crystal of 87-93 mass parts, the left-handed chiral dopant of 3~4 mass parts, the monomer of 3~5 mass parts and 0.5~ The photoinitiator of 1 mass part is mixed, obtains mixed liquid crystal material B, and wherein, described liquid crystal is negative liquid crystal and is LC-2079, and de...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, except that: the left-handed chiral dopant is S1011 from Merck, Germany, the right-handed chiral dopant is R1011, and the lowermost The conductive layer 2 on the upper surface of the substrate 1 is connected to the negative pole of the first DC power supply 8, the conductive layer 2 on the lower surface of the substrate 1 in the middle is connected to the positive pole of the first DC power supply 8, and the uppermost one is connected to the positive pole of the first DC power supply 8. The conductive layer 2 on the lower surface of the substrate 1 is connected to the positive pole of the second DC power supply 9 , and the conductive layer 2 on the upper surface of the substrate 1 arranged in the middle is connected to the negative pole of the second DC power supply 9 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com