Auxiliary tooling for punching laminated lithium-ion battery pole pieces and punching method

A lithium-ion battery and auxiliary tooling technology, which is applied in the field of lithium-ion batteries, can solve the problems of large numerical deviation of photosensitive infrared sensors, poor surface flatness of electrodes, and excessive exposed foil of pole pieces, so as to improve the qualified rate of punching and improve Consistency, the effect of avoiding unsafe factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

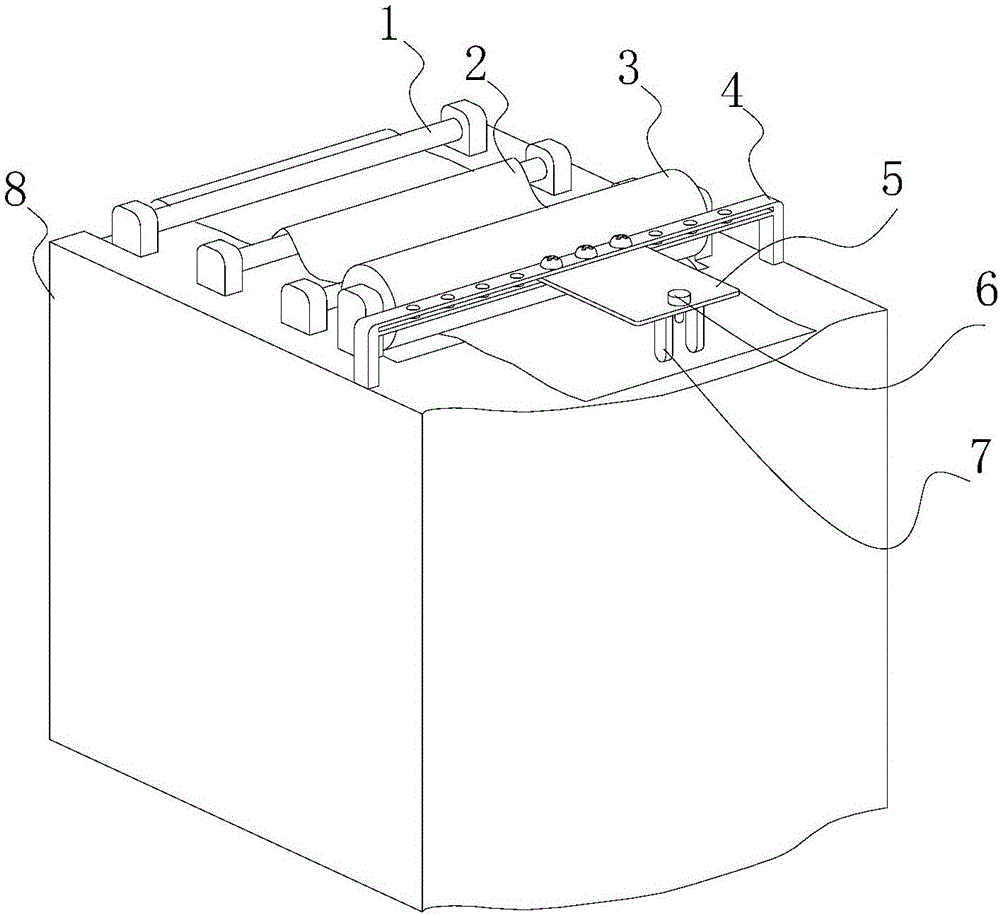

[0037] see Figure 1 to Figure 2 , an auxiliary tooling for die-cutting of laminated lithium-ion battery pole pieces, including:

[0038] Support base 1; the upper surface of the support base is a plane;

[0039] Roller 1, pressure roller 3, and fixed bracket 4 installed on the upper surface of the support base; the central axes of the roller and the pressure roller are parallel to each other; the pressure roller is located between the roller and the fixed bracket;

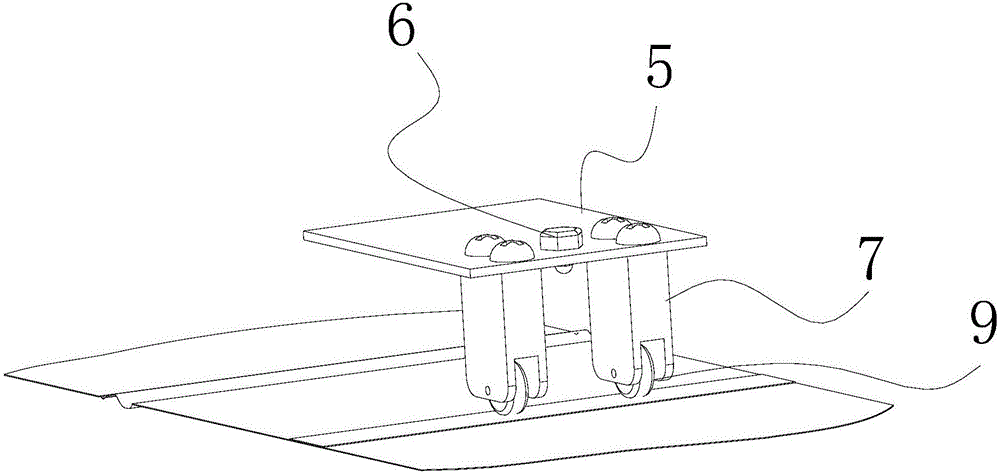

[0040] The adjusting plate 5 installed on the fixed bracket; the adjusting plate 5 is parallel to the upper surface of the support base 8; the photosensitive infrared sensor 6 is installed on the adjusting plate; the lower surface of the adjusting plate is fixed with at least tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com