High-nickel cathode material, preparation method thereof and lithium ion battery

A technology for lithium ion batteries and positive electrode materials, which is applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve problems such as poor thermal stability, and achieve the effects of improving thermal stability, improving properties, and simple and easy methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

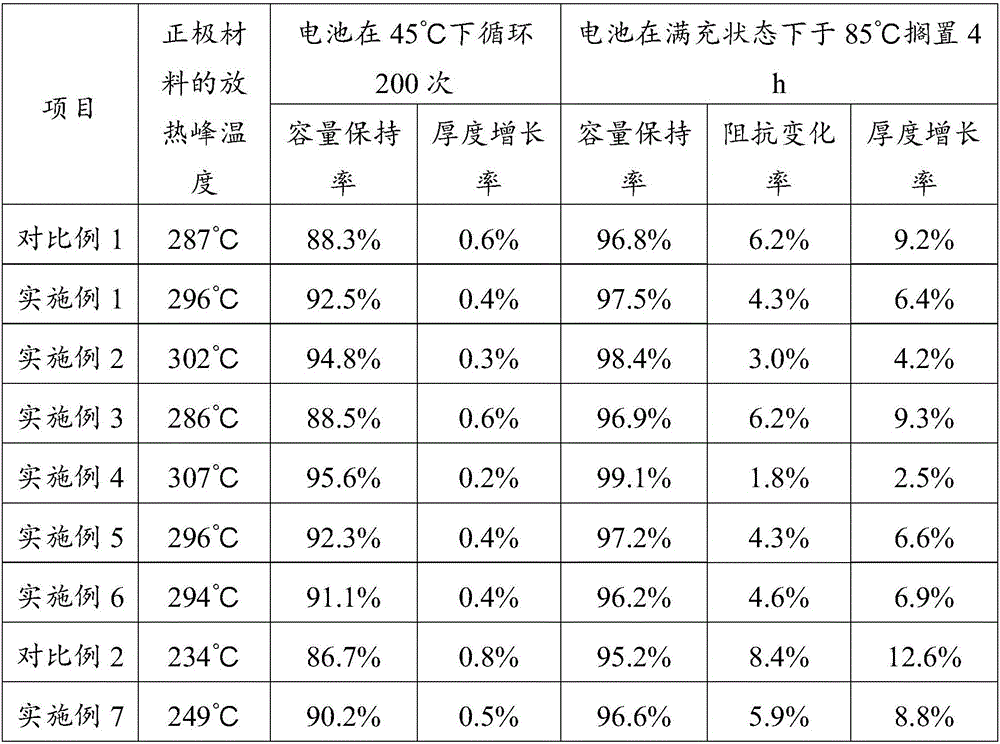

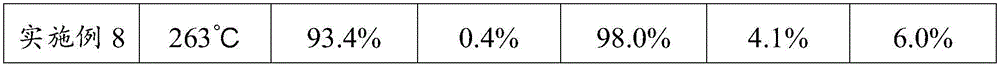

Embodiment 1

[0046] 200 parts by mass of Ni, Co, Mn in a molar ratio of 5:2:3 carbonate coprecipitate precursor and 1.8 parts by mass of lithium metasilicate were added to 200 parts by mass of deionized water and dispersed under mechanical stirring 2h to obtain the slurry; dry the resulting slurry at 120°C for 12h to obtain the precursor mixture; weigh 100 parts of the mass of the precursor mixture, add 31.76 parts of the mass of lithium carbonate (99.0%), in a three-dimensional mixer under the condition of 25Hz Mixed at low temperature for 4 hours, and then placed in a box-type furnace under an air atmosphere at 680°C for 6 hours; after cooling to room temperature, re-sintered at 960°C under an oxygen atmosphere for 12 hours, and passed through a 400-mesh standard sieve after cooling to obtain silicon doped Nickel cobalt lithium manganese oxide cathode material, also using DSC to test its exothermic peak temperature. Subsequently, according to the process conditions described in Comparati...

Embodiment 2

[0048] According to the same component content and process conditions in Example 1, the nickel-cobalt lithium manganate positive electrode material was prepared, but the quality of lithium metasilicate was increased from 1.8 parts to 3.6 parts, and the quality of lithium carbonate was reduced from 31.76 parts to 31.48 parts. Parts, the nickel-cobalt-lithium-manganese-oxide cathode material doped with silicon was obtained, and the exothermic peak temperature was also measured by DSC. Subsequently, according to the process conditions described in Comparative Example 1, the obtained positive electrode material was used to manufacture a polymer pouch battery of the same type, and its high-temperature cycle performance and high-temperature storage performance were also tested.

Embodiment 3

[0050] According to the same component content and process conditions in Example 1, the nickel-cobalt lithium manganese oxide positive electrode material was prepared, but the quality of lithium metasilicate was reduced from 1.8 parts to 0.08 parts, and the quality of lithium carbonate was increased from 31.76 parts to 32.03 parts. Parts, the nickel-cobalt-lithium-manganese-oxide cathode material doped with silicon was obtained, and the exothermic peak temperature was also measured by DSC. Subsequently, according to the process conditions described in Comparative Example 1, the obtained positive electrode material was used to manufacture a polymer pouch battery of the same type, and its high-temperature cycle performance and high-temperature storage performance were also tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap