Wire pressing groove for wire arrangement

A wire crimping trough and wire technology, applied in the field of crimping troughs, can solve problems such as time-consuming and laborious arrangement of wires, disordered arrangement of wires, threats to life and property, etc., and achieve the effects of high installation efficiency, extended service life, and flexible connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

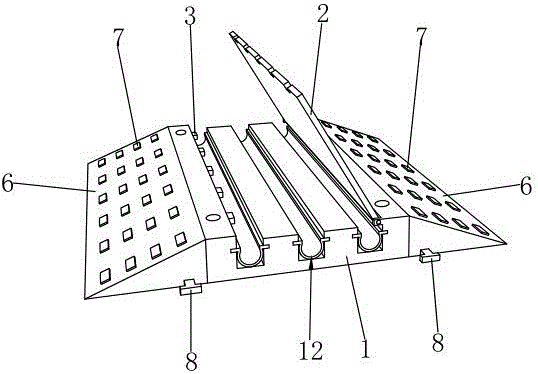

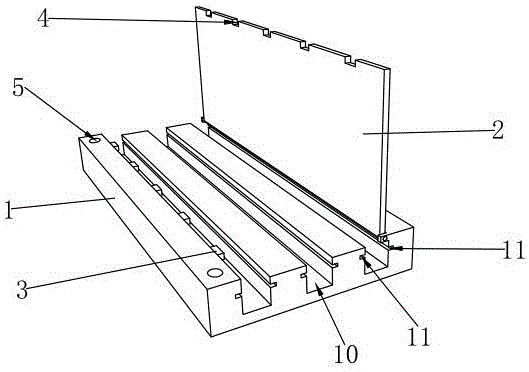

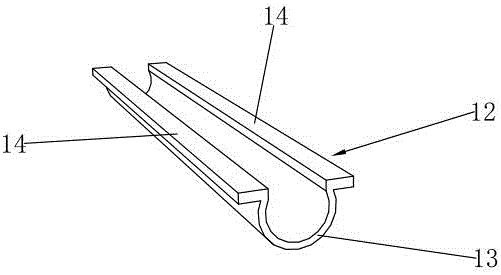

[0019] Such as Figure 1 to Figure 4 As shown, it is a crimping trough for arranging electric wires according to the present invention, which includes a trough body substrate 1 and a cover plate 2, the trough body substrate 1 is connected to the cover plate 2, and the slot body substrate 1 is evenly distributed with locking protrusions 3, Openings 4 are evenly distributed on one side of the cover plate 2 , and the openings 4 are matched with the locking protrusions 3 , and the cover plate 2 is stably closed through mutual restraint between the openings 4 and the locking protrusions 3 . The surface of the cover plate 2 is provided with anti-slip lines to improve the friction performance of the surface of the cover plate 2 and prevent pedestrians from accidentally slipping on the cover plate 2 when stepping on it. The tank substrate 1 is provided with a through-mounting hole 5, and a ground anchor is used to insert a fixing bolt into the through-mounting hole 5 to fix the tank s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com