Core structure for power supply device of electric vehicle

A technology for power supply devices and electric vehicles, which is applied in the direction of electric vehicle charging technology, electric vehicles, battery circuit devices, etc., which can solve problems such as difficulty in setting up operations, rising costs of power supply lines, and rising costs of power supply system construction, so as to improve power transmission efficiency , The effect of reducing the overall setup cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. In the drawings, the same reference numerals are assigned to the same structural elements at all positions. Also, detailed descriptions of well-known functions and configurations that may obscure the gist of the present invention will be omitted.

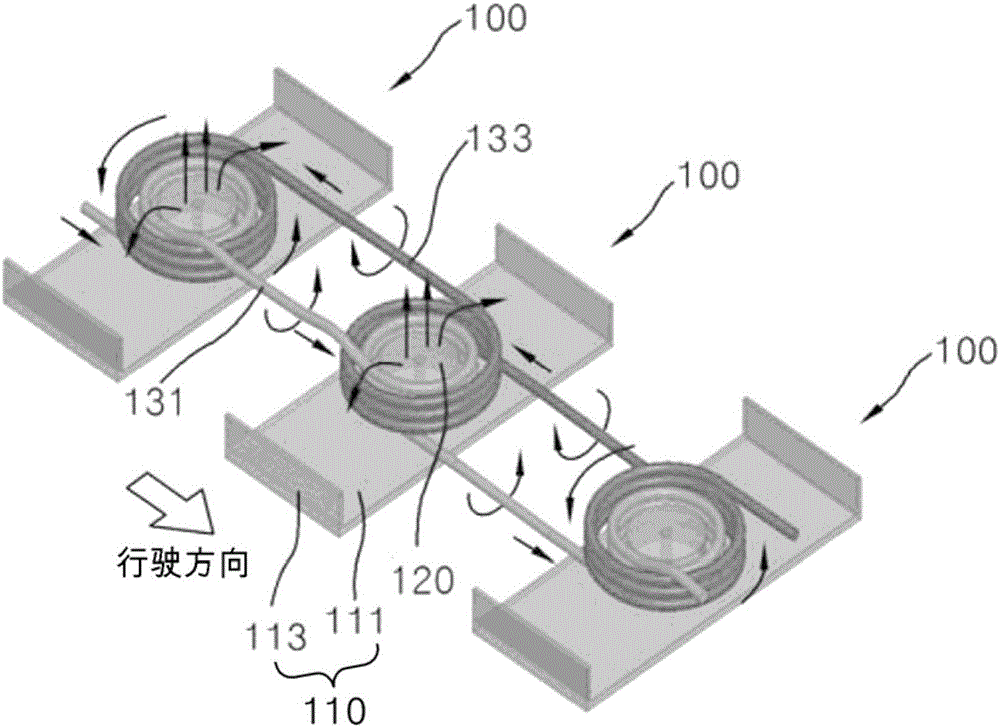

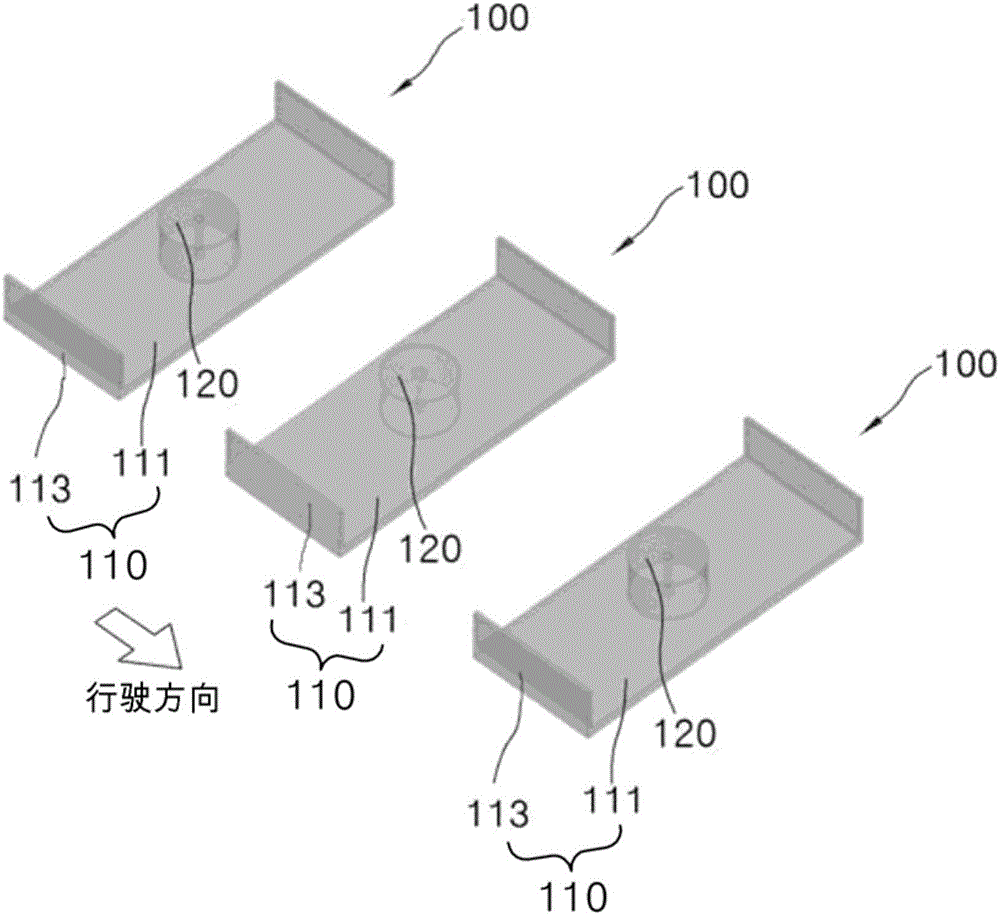

[0055] figure 2 A plate core structure showing an embodiment of the present invention, figure 2 To show a perspective view of a power supply device with a unipolar double power supply coil structure, Figure 3a to Figure 3c to show figure 2 The perspective view, side view, and top view of the substrate and column in the plate core structure shown, the "plate core structure" is a structure in which the substrate 110 formed in the shape of "匚" is formed by a rectangular plate, "wherein, the power supply The "coil structure" is a structure in which a power supply coil is double wound on a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com