Annular electrode for electric car charging, charging system and working method

A ring electrode and charging system technology, which is applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problem of inaccurate docking of docking electrodes, and achieve the effect of precise electrode docking and high power transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

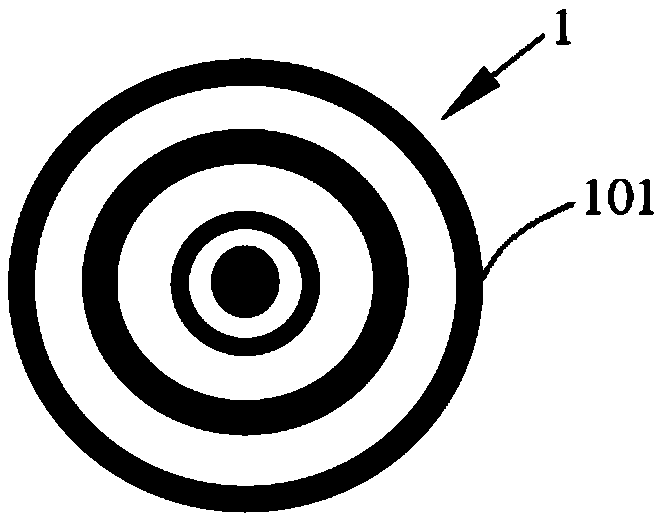

[0025] figure 1 It is a structural diagram of the ring electrode of the present invention.

[0026] In this example, if figure 1 As shown, the present invention provides a ring electrode 1 , which includes: several concentric ring-shaped electrode coils 101 .

[0027] In this embodiment, when charging, the two butt-connected electrodes use a ring-shaped electrode 1 composed of several concentric ring-shaped electrode coils 101, which makes the control of the electrodes more convenient when they are connected, the connection is more accurate, and the power transmission efficiency is higher. high.

Embodiment 2

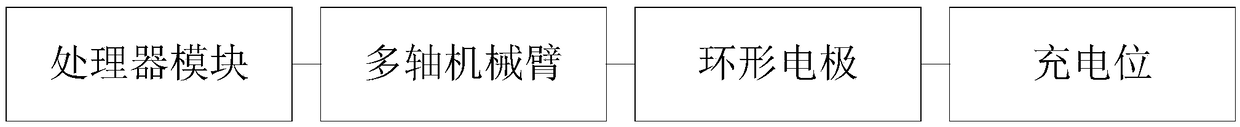

[0029] figure 2 It is the control schematic diagram of the charging system of the present invention;

[0030] In this example, if figure 2 As shown, this embodiment provides a charging system, including: a processor module, a multi-axis manipulator 2 and a ring electrode 1; wherein the processor module is suitable for controlling the multi-axis manipulator 2 to drive the ring electrode 1 to move to the charging position .

[0031] In this embodiment, the processor module may be, but not limited to, an embedded processor, such as an STM32 processor.

[0032] In this embodiment, the multi-axis robotic arm 2 may be, but not limited to, a three-axis robotic arm, and key motors of each robotic arm are controlled by the processor module.

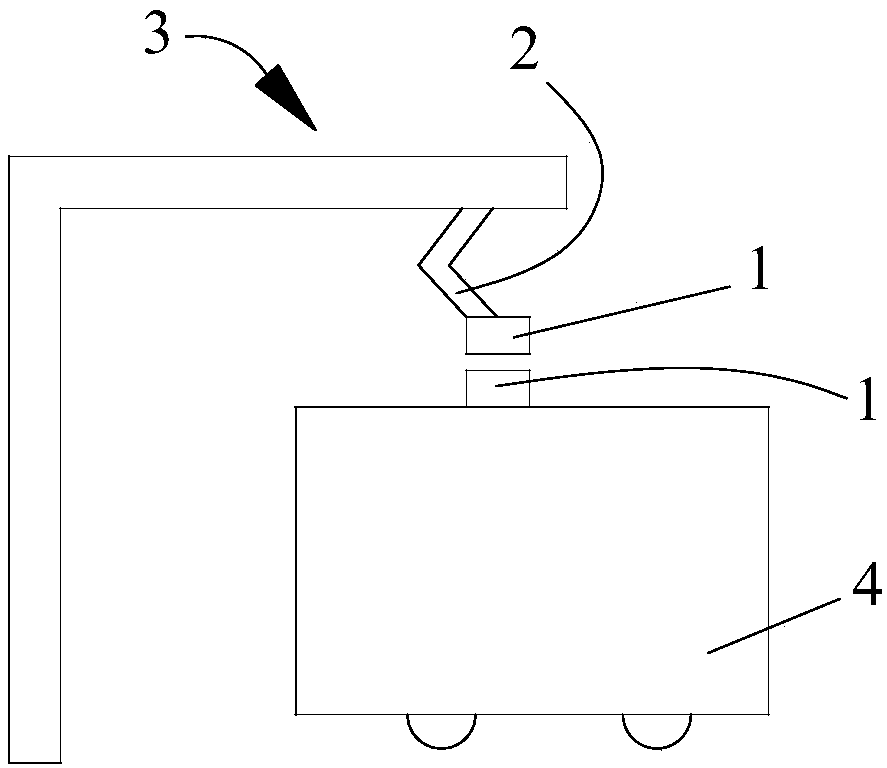

[0033] image 3 It is a structural schematic diagram of the first embodiment of the charging system of the present invention.

[0034] In order to charge electric vehicles 4, such as image 3 As shown, the charging system further includes:...

Embodiment 3

[0043] Such as Figure 4 As shown, in this embodiment, this embodiment provides an electric vehicle 4 equipped with the ring electrode 1 provided in Embodiment 1.

[0044] In order to charge the electric vehicle 4, a multi-axis mechanical arm 2 is arranged on the top of the electric vehicle 4; a processor module is suitable for controlling the multi-axis mechanical arm 2 to drive the ring electrode 1 to the charging position to connect with the charging bow The ring electrode 1 provided on the power supply catenary 5 at the end of 3 is docked to realize power transmission.

[0045] Specifically, the processor module can be used as a control module of the multi-axis robot arm, and the operation process of the multi-axis robot arm can refer to the specific content of Embodiment 2. The processor module may, but is not limited to, use an STM32 processor.

[0046] In this embodiment, the electric vehicle 4 is installed with electrodes as provided in embodiment 1, so that the floo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com