Orthodontic apparatus and method for producing an orthodontic apparatus

A manufacturing method and orthopedic technology, applied in the field of jaw orthopedics, can solve the problems of patient discomfort, consumption, waiting time, etc., and achieve the effect of fast and accurate manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

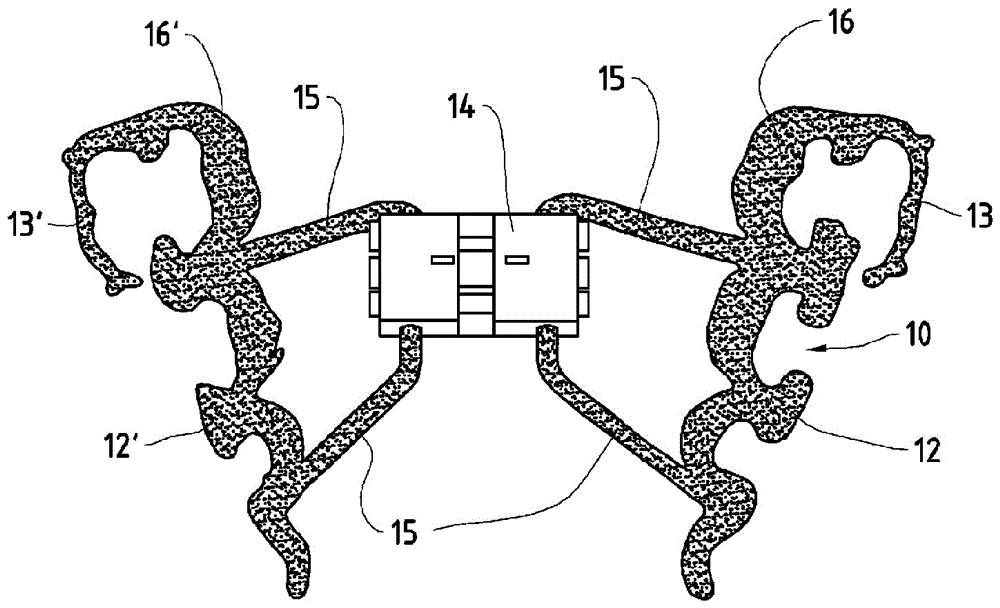

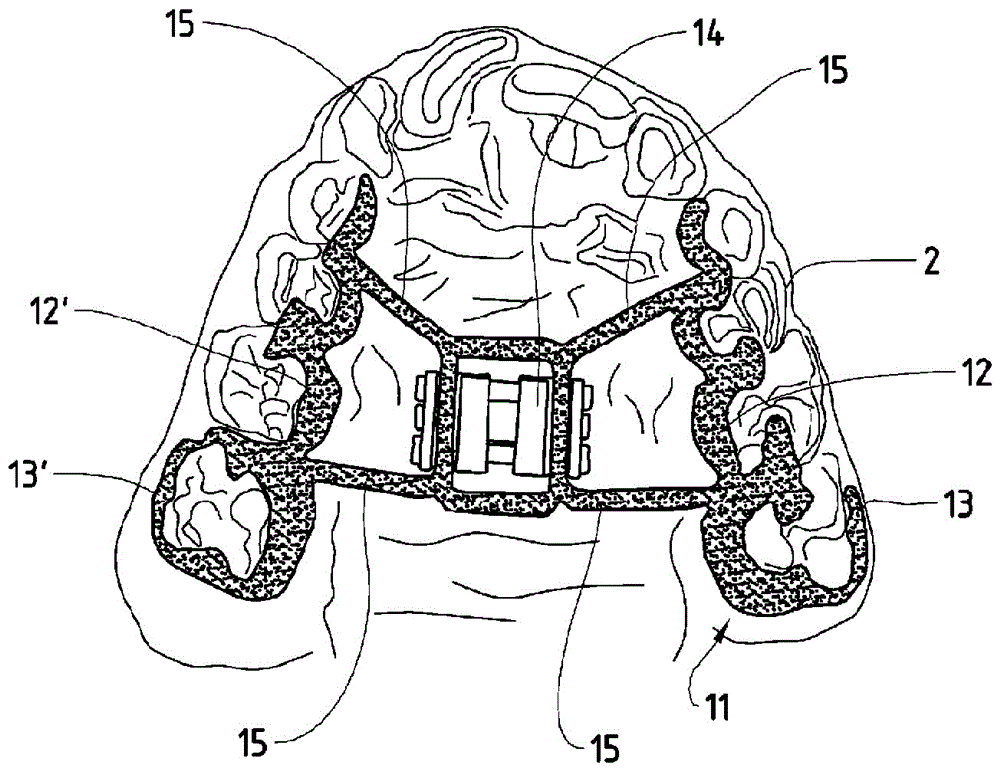

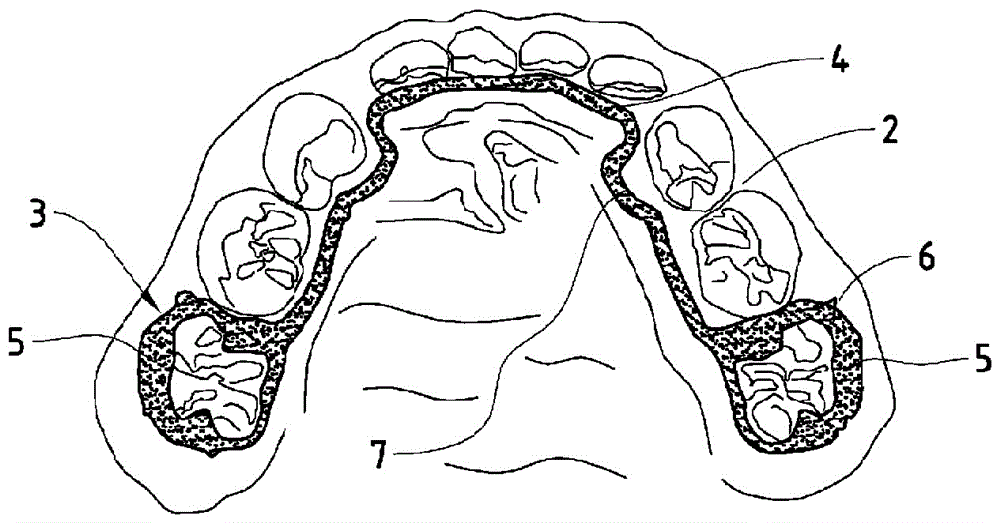

[0030] figure 1 Shown is a part derived from a graph in the case of modeling a first mechanism 1 of jaw orthopedics, as described in figure 2 as shown in. exist figure 1 3D shows a representation of a three-dimensional jaw model 2 of a lower jaw with teeth, as determined from the electronic data record for the jaw model. The data record is obtained from a graph taken in the patient's mouth. In addition, a three-dimensional model of the mechanism, a graphic representation of the mechanism model 3 , is shown, as determined from the electronic data record for the mechanism model. The mechanism model 3 includes a wire-shaped jaw-orthopedic element 4 which extends on the inner side of the jaw along a plurality of teeth. The jaw-orthopedic element 4 rests on the front teeth on the inside and follows the contour of the teeth in order to be supported on the teeth. In addition, the wire-shaped element 4 has a tensioning collar 7 . The elements 4 extend along the lateral region o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com