Manufacturing method and nitriding treatment equipment of grain-oriented electrical steel sheet

A technology of electromagnetic steel sheet and manufacturing method, which is applied in the direction of heat treatment equipment, lighting and heating equipment, manufacturing tools, etc., can solve the problems such as lack of magnetic properties, and achieve the effect of suppressing deterioration and good properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

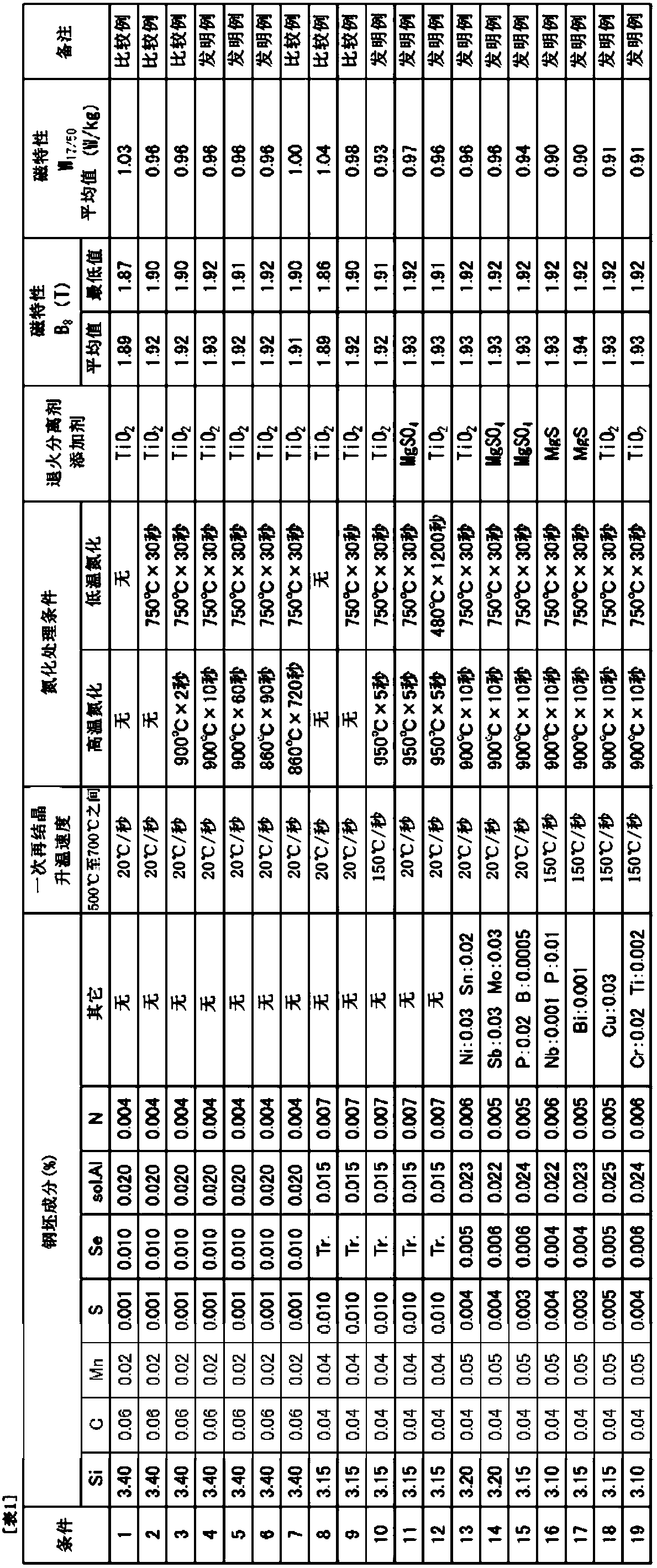

[0127] The slabs for various grain-oriented electrical steel sheets shown in Table 1 were heated at 1230° C. and then hot-rolled to form hot-rolled sheets with a thickness of 2.5 mm. Hot-rolled sheets were annealed at 1050° C. for 1 minute. Then, it was cold-rolled to a final thickness of 0.27 mm, and a sample of size 100 mm×400 mm was cut out from the center of the obtained cold-rolled coil, and annealing for primary recrystallization and decarburization was performed in a laboratory.

[0128] Next, nitriding treatment was performed under the nitriding conditions shown in Table 1 in a mixed atmosphere of ammonia gas, hydrogen gas, and nitrogen gas. In addition, regarding the temperature increase rate of the primary recrystallization annealing, the temperature increase rate between 500° C. and 700° C. was set at two levels of 20° C. / sec and 150° C. / sec.

[0129] In addition, in this example, 21 or 20 steel sheets under the same conditions were produced for each condition. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com