Drum-type washing machine

A drum-type washing machine and drum technology, which is applied to other washing machines, control devices of washing machines, washing devices, etc., can solve the problems of slow movement of moving bodies, enlarged vibrations, and inability of moving bodies to move, and achieve the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

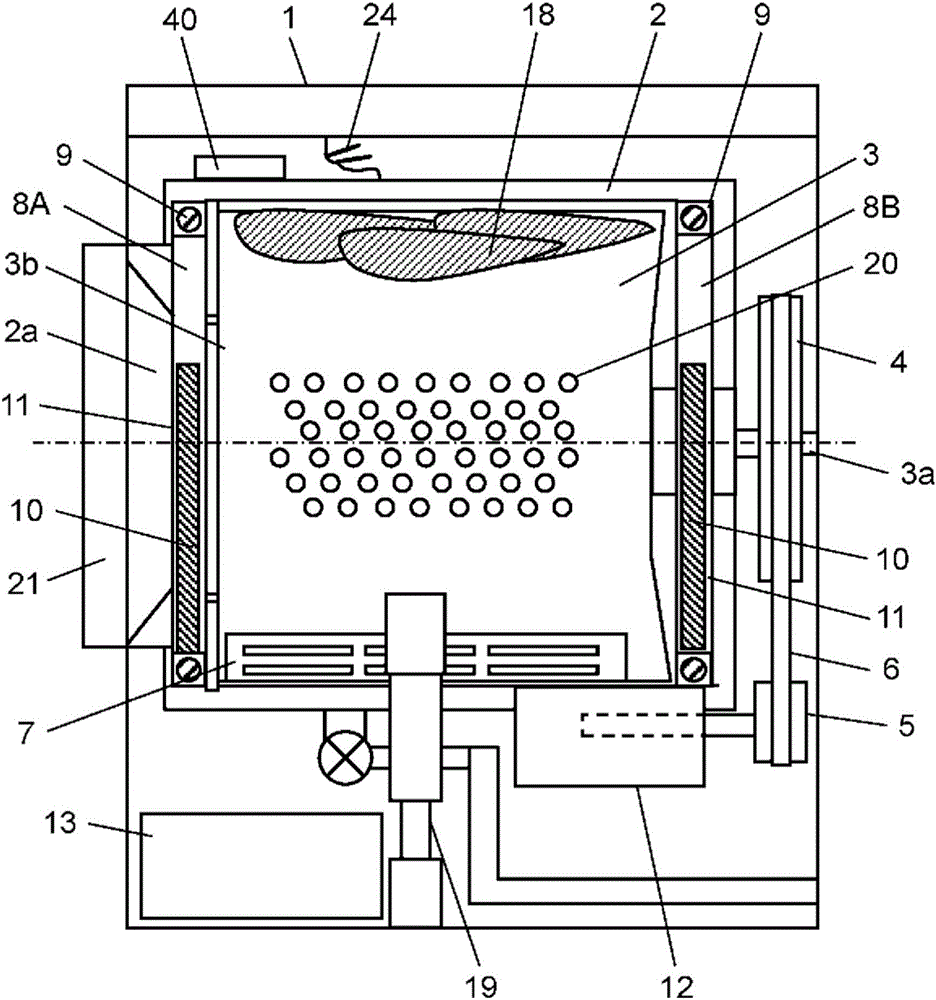

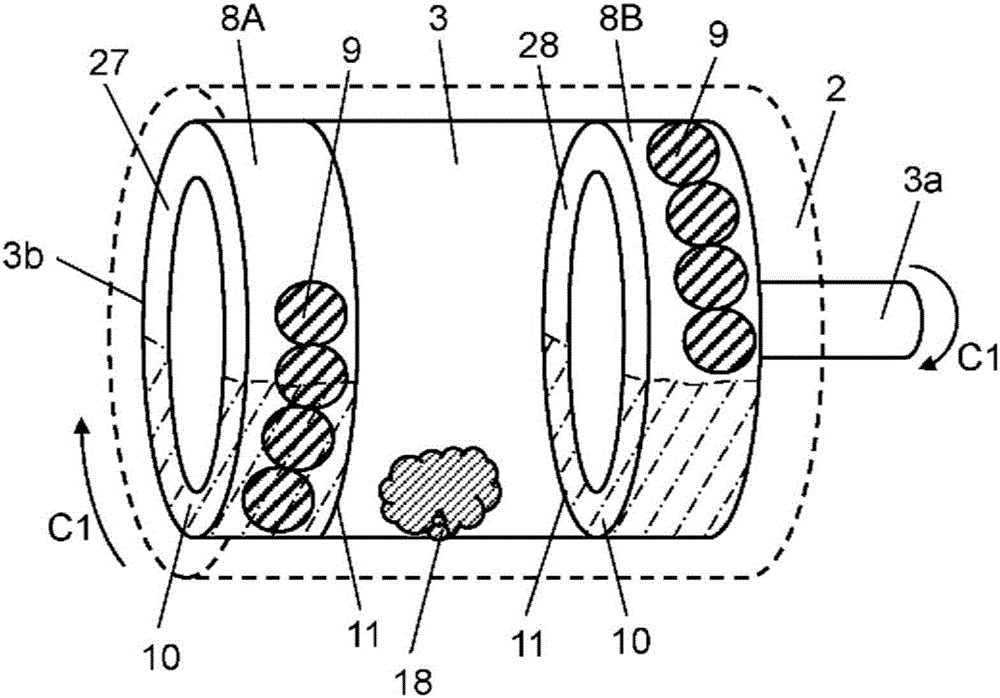

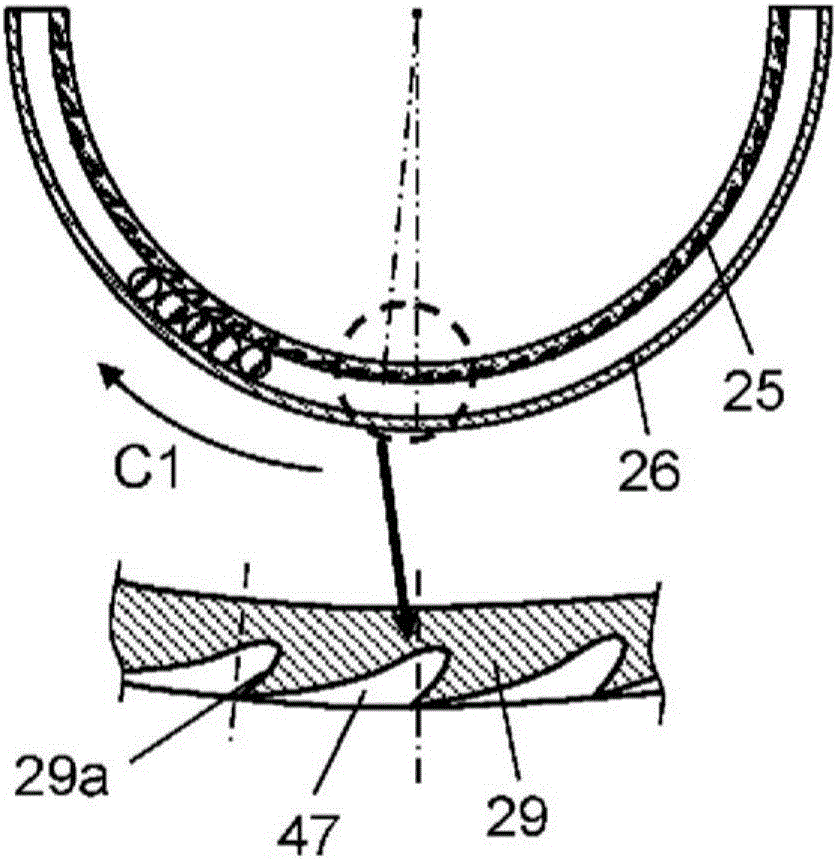

[0040] figure 1 It is a side cross-sectional view showing the internal schematic structure of the front-loading-type washing machine in Embodiment 1 of this invention. A bottomed cylindrical water tank 2 is accommodated inside the main body 1 . The water tank 2 is elastically supported by the spring 24 and the shock absorber 19 . A bottomed cylindrical drum 3 is accommodated inside the water tank 2 . On the front side of the main body 1, an opening 2a of the water tank 2 and an opening 3b of the drum 3 are provided, and a door 21 for opening and closing the opening 2a of the water tank 2 is provided. The drum 3 is supported so that the rotating shaft 3a is in a horizontal direction (including a substantially horizontal direction). In addition, the present invention is not limited to this structure, for example, considering the ease of taking out the laundry 18 and water saving during washing, the rotating shaft 3a of the drum 3 may be configured to be inclined downward from...

Embodiment approach 2

[0080] The control unit of the front-loading washing machine in Embodiment 2 is configured to increase the rotation speed of the drum to a predetermined rotation speed slightly higher than the resonance rotation speed, and measure vibration with the vibration detector 40 to determine a change in the vibration value while the predetermined rotation speed is maintained. Then, based on this determination, the maintenance time of the predetermined rotational speed is changed, and the rotational speed of the drum is increased to a stable rotational speed. The other structures of the front-loading washing machine are the same as those of Embodiment 1, and the structure of Embodiment 1 is quoted.

[0081] Figure 8 It is a flowchart of the unbalance reduction process in the spin-drying process of the front-loading-type washing machine in Embodiment 2 of this invention. Such as Figure 8 As shown, when the dehydration process starts (step 1), unbalance detection is performed, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com