Feedthroughs for multi-chamber pressure vessels

A technology of inner chamber and shape, applied in the field of new connectors, can solve the problems of difficult separation of liquid tightness and air tightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

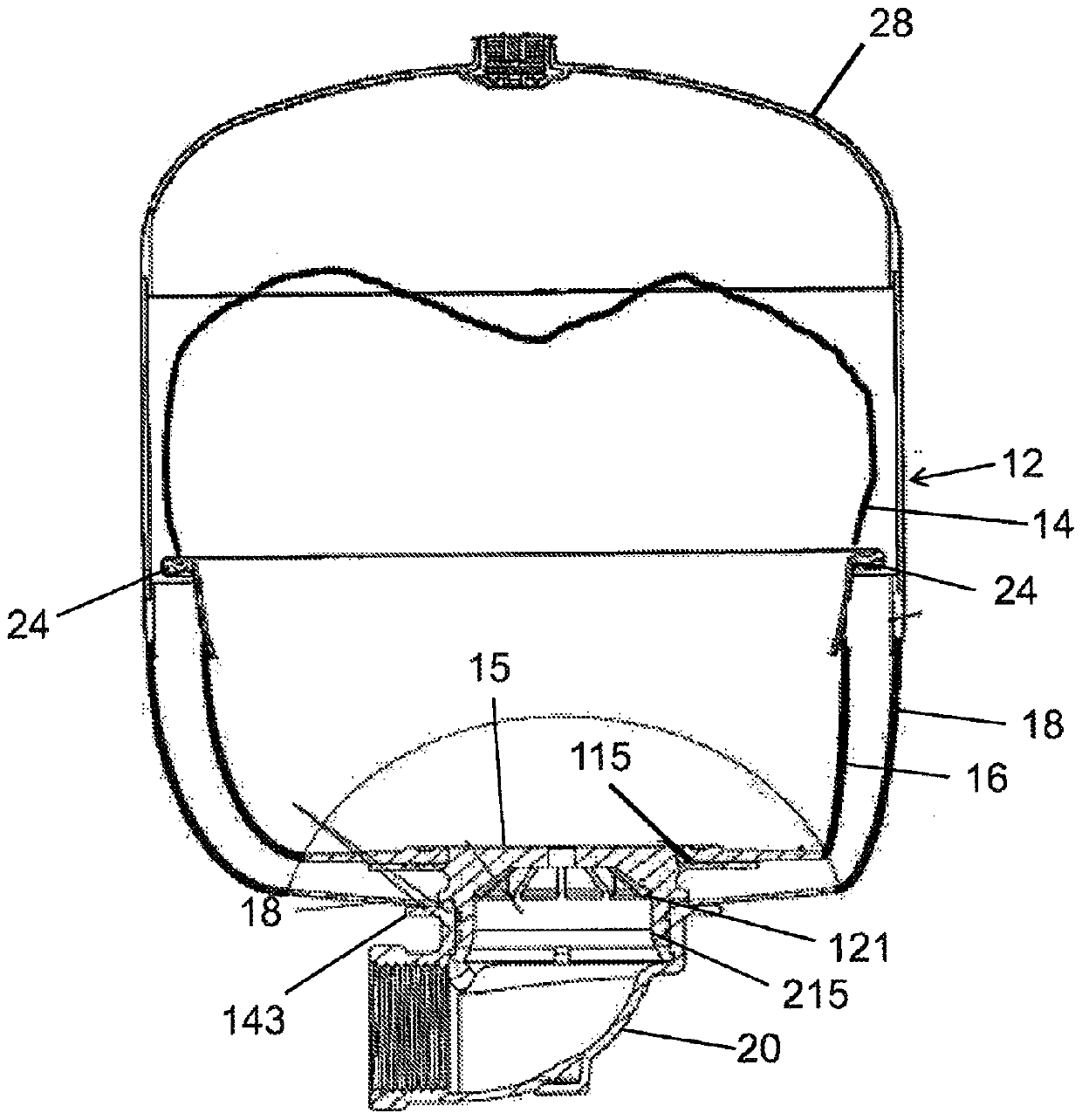

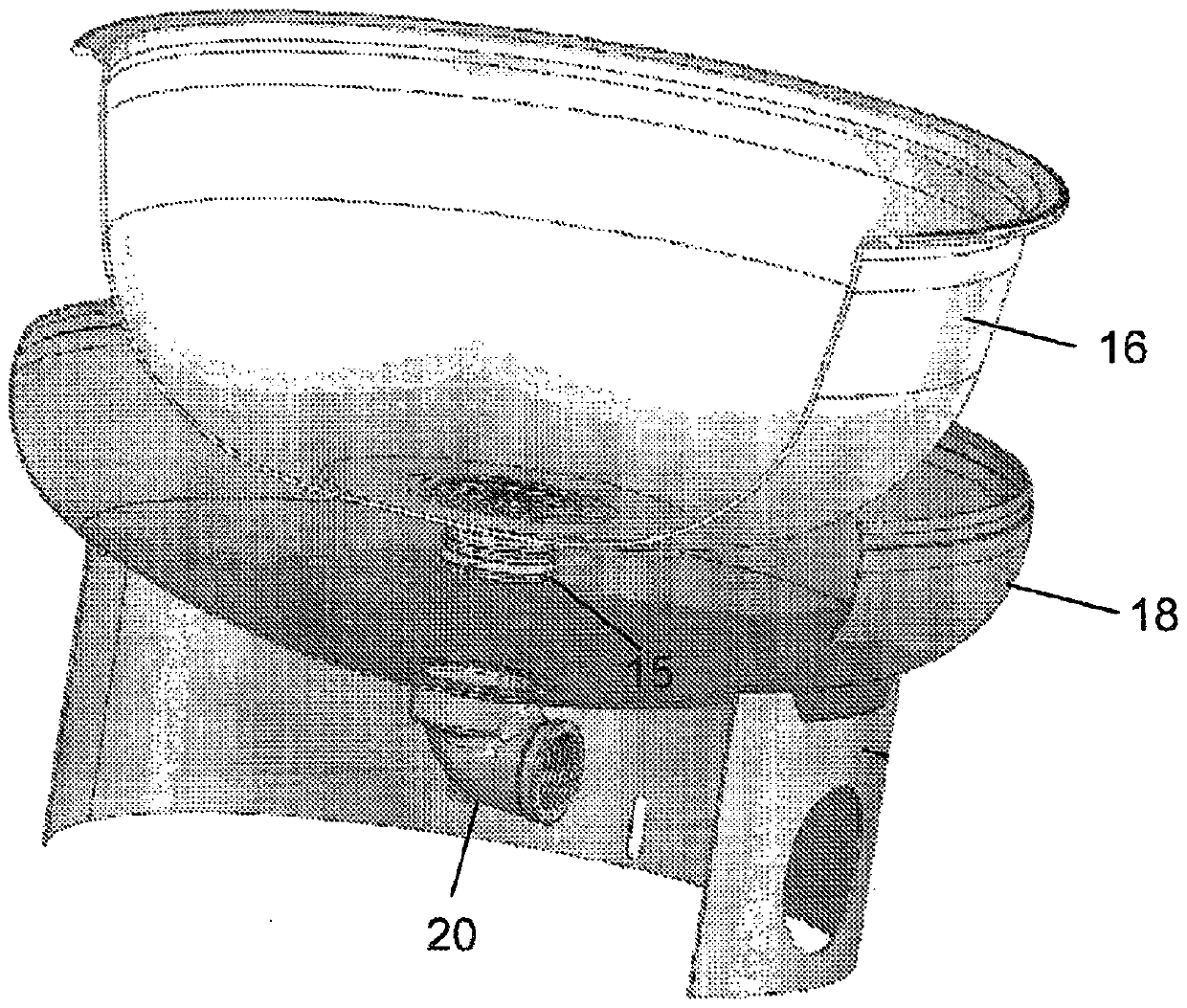

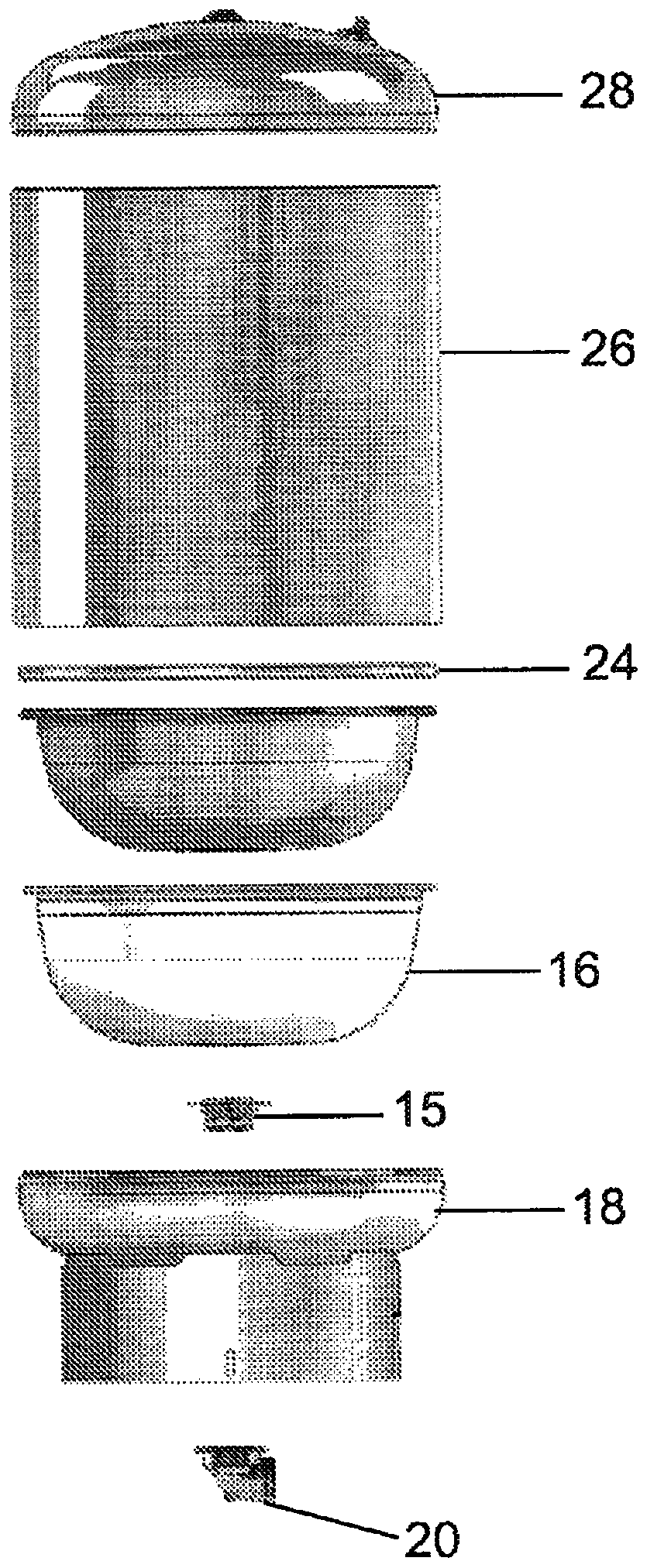

[0023] The assembly of the present invention provides fluid communication between the exterior and interior chambers of the pressure vessel while maintaining the integrity of the pressure vessel and isolating the pressurized gas chamber of the pressure vessel from the inner liquid holding chamber. Isolating the pressurized gas chamber from the inner chamber provides a change in pressure without being affected by atmospheric pressure outside the pressure tank.

[0024] The outer wall of the tank 12 is preferably a steel shell formed in three sections, a top cover 28, a central cylinder 26 and a lower cup 18 formed of steel or other rigid, preferably metallic material. . Supported within the outer wall of the tank 12 is an inner liquid chamber defined by at least one flexible membrane 14 and a lower liner 16; the lower liner may be flexible or rigid, or can be at least partially fixed to the tank Lining of the inner surface of the outer rigid wall. The lower liner 16 is in tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com