A kind of cultivation light environment and cultivation method of lettuce vegetables

A cultivation method and light environment technology, applied in botany equipment and methods, cultivation, gardening methods, etc., can solve the problems of not raising the light intensity, increasing the operating cost of plant factories, and being easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

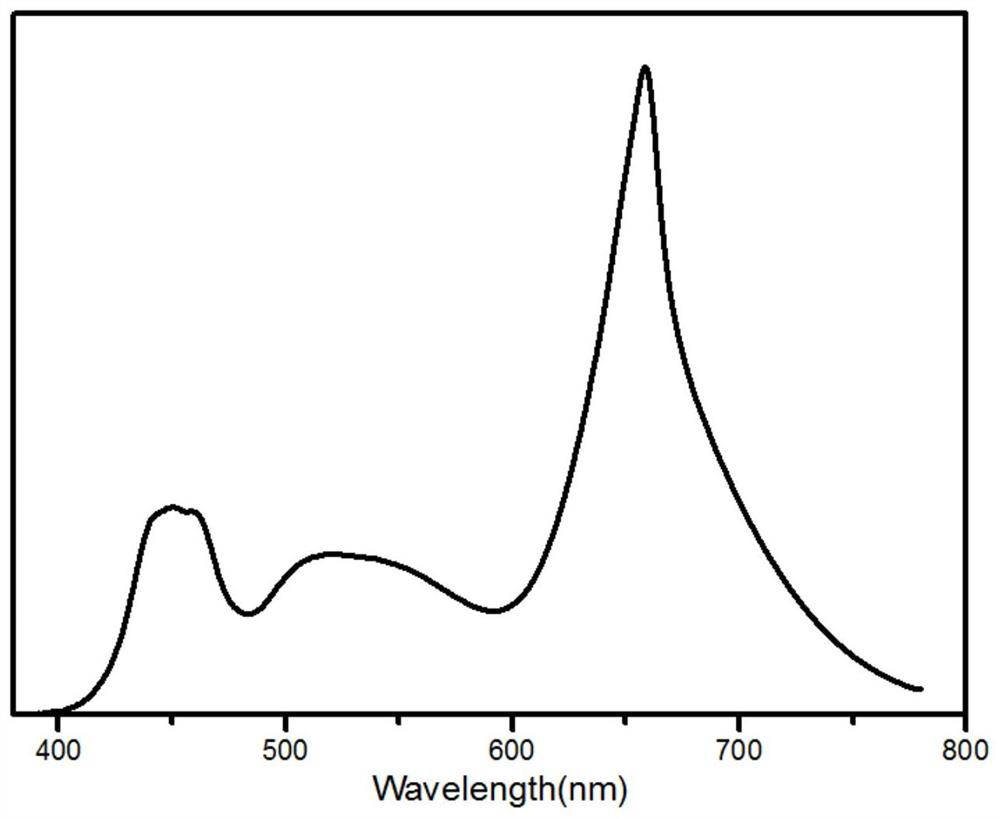

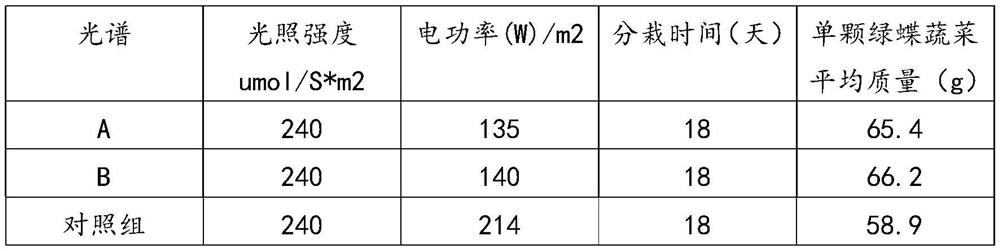

[0020] Plant group A of green butterfly seedlings with the same specifications on special hydroponic equipment, and set the light environment parameters as follows: Spectrum A is shown in the table below, and the light intensity is 240umol / m 2 *s, photoperiod 8h / d, ambient temperature 20-23°C; parameters of nutrient solution used in hydroponics: PH value 6.5-7.5, EC value controlled at 1.2-1.5, liquid temperature 20-22°C, dissolved Oxygen amount 5-6mg / L split planting time 18 days, using Philips-T5 fluorescent lamp as a control test, the yield increased by 11%:

[0021] wavelength(nm) Light Quantum Number Distribution Ratio Light intensity (umol / m 2 *s)

380-399 0.05% 0.12 400-499 13.65% 32.67 500-599 18.52% 44.45 600-699 54.07% 129.77 700-780 13.71% 32.90 436 1.22% 0.40 480 0.89% 0.30 630 0.79% 1.03 660 1.87% 2.43 730 1.38% 0.45

[0022] The number of photons with a wavelength of 400-499nm accoun...

Embodiment 2

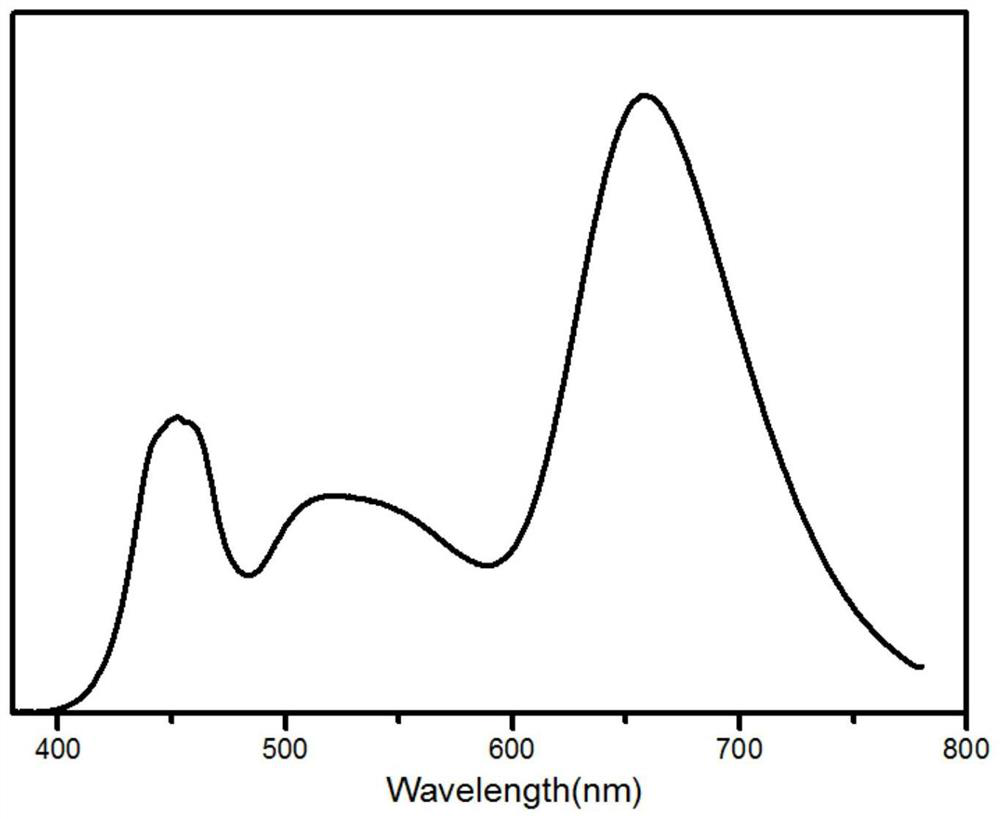

[0027] Plant group B of green butterfly seedlings with the same specifications on special hydroponic equipment, and set the light environment parameters as follows: Spectrum B is shown in the table below, and the light intensity is 240umol / m 2 *s, photoperiod 8h / d, ambient temperature 22-23°C, parameters of nutrient solution used in hydroponics: PH value 6.5-7.5, EC value 1.2-1.5, liquid temperature 20-22°C, dissolved oxygen The amount of 5-6mg / L was planted for 18 days, and the Philips-T5 fluorescent lamp was used as a control experiment, and the yield was increased by 12.4%:

[0028] wavelength(nm) Light Quantum Number Distribution Ratio Light intensity (umol / m2*s) 380-399 0.05% 0.12 400-499 13.45% 32.28 500-599 18.65% 44.76 600-699 50.90% 122.16 700-780 16.95% 40.68 436 1.23% 0.40 480 0.88% 0.28 630 0.89% 1.08 660 1.37% 1.67 730 1.39% 0.56

[0029] The test result record of embodiment 1 and 2 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com