Artificial hip joint femoral stem

A hip joint and femoral stem technology, applied in the field of human implant prosthesis, can solve the problem that the femoral stem cannot meet the requirements of jumping, running, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

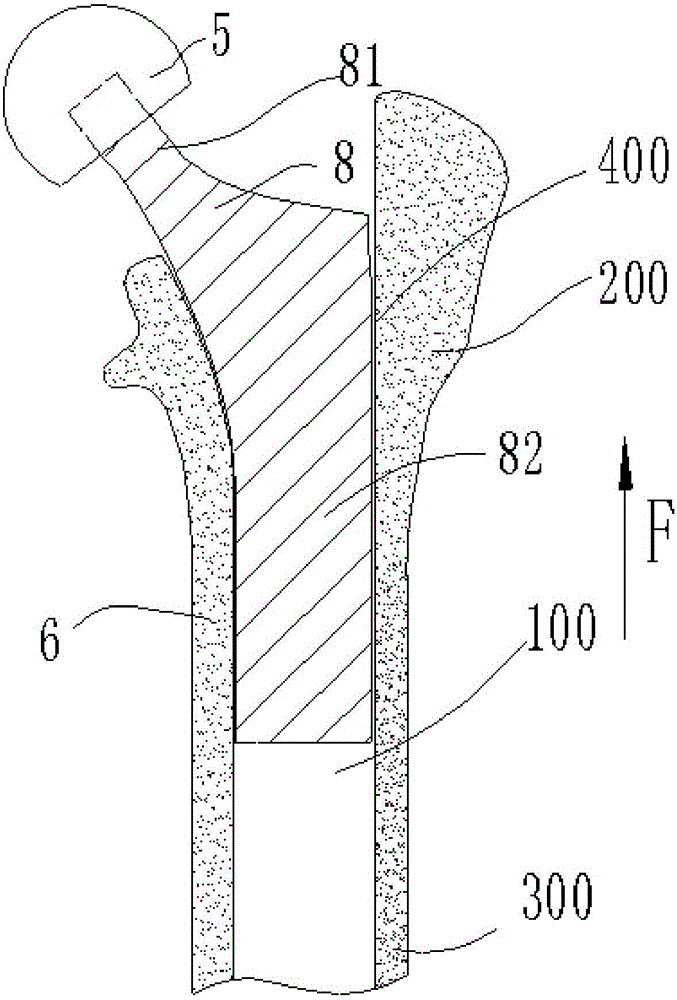

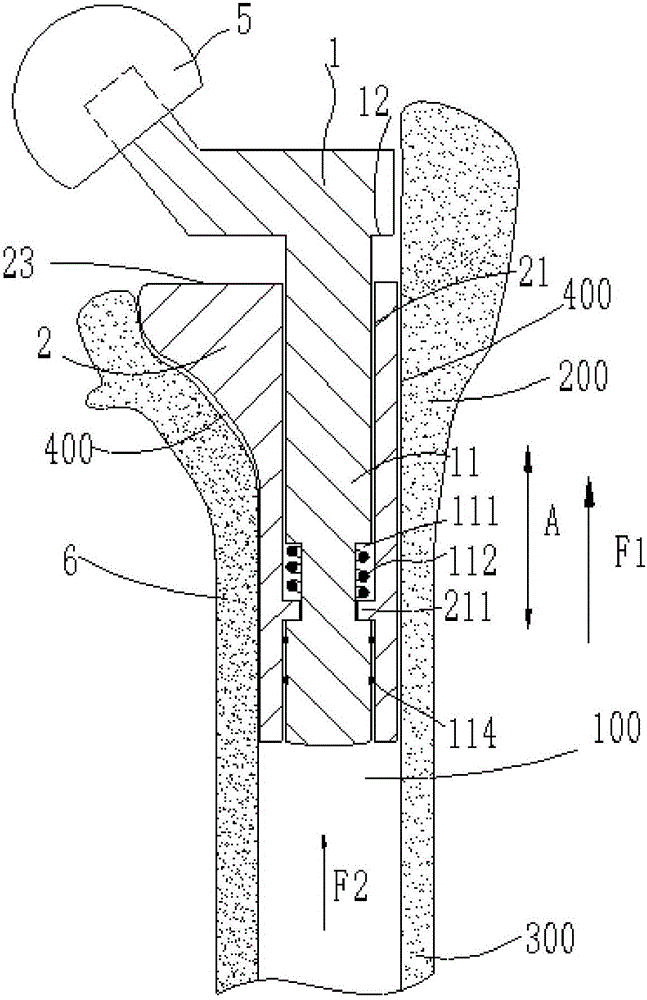

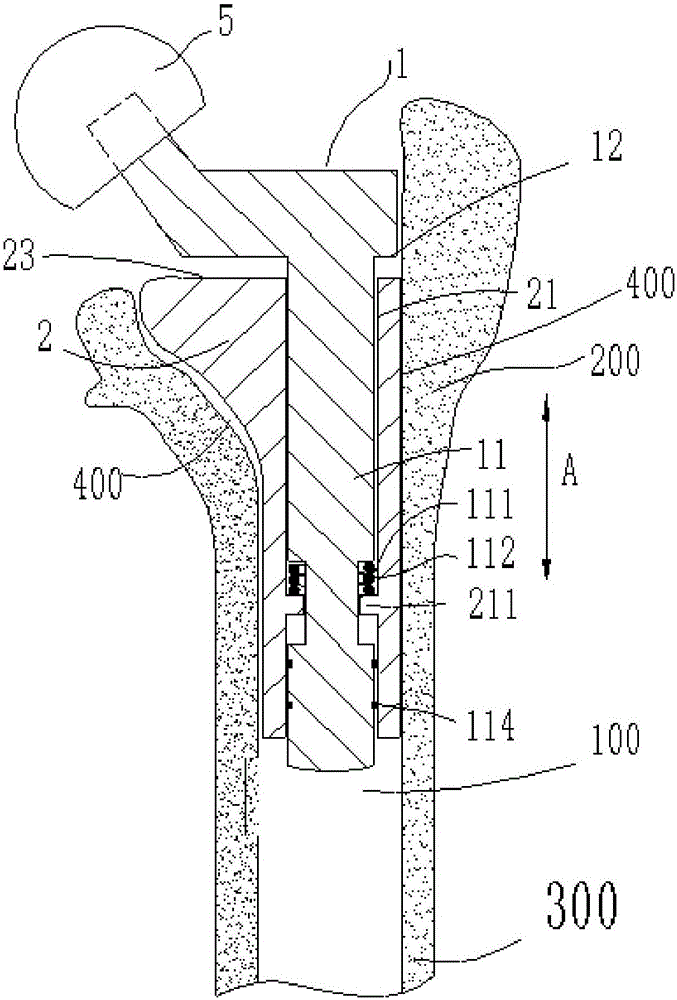

[0030] Such as figure 2 As shown, the femoral stem of the present invention includes a femoral neck 1 and a stem body 2 . The upper end of the femoral neck 1 is usually an oblate structure, the upper end of the femoral neck 1 is connected with the femoral head 5, and is coupled with the acetabular cup (not shown) by the femoral head 5, and the handle 2 is connected with the femoral head 5. It is inserted into the bone marrow cavity 100 of the femur 6 . The part of the handle body 2 and the bone ingrowth of the femur 6 is the proximal end, and the part that is away from the bone ingrowth into the medullary cavity (100) is the distal end. A channel 21 is provided in the handle body 2 , and the channel 21 is a through hole with upper and lower openings, and the channel 21 communicates with the bone marrow cavity 100 through its open lower end. And the femoral neck 1 has a transmission rod 11 extending downward from the upper end, the transmission rod 11 is inserted into the ch...

no. 2 example

[0041] The structure of the second embodiment is basically the same as that of the first embodiment, except that the groove of the transmission rod and the flange of the channel are interchanged. Such as Figure 5 As shown, there is a second annular groove 214 inside the channel 21 of the handle body 2, and a second annular flange 115 is provided on the transmission rod 11, and the second annular flange 115 is embedded in the second annular groove 214 , and a second elastic element, such as a spring 116 , is disposed in the second annular groove 214 . When the femoral neck 1 is under pressure, the transmission rod 11 presses down the spring 116, and its working principle is the same as that of the first embodiment. The description of its working process is omitted here.

no. 3 example

[0043] The structure of the third embodiment is basically the same as that of the first embodiment, as Figure 6 As shown, only the annular groove on the transmission rod 11 and the annular flange on the channel 21 are canceled, and the spring 112 is arranged between the lower surface of the femoral neck 1 and the upper surface of the handle body 2 . By directly compressing the spring 112 through the lower surface of the femoral neck 1, the processing procedure of the femoral stem can be simplified. In addition, a tough block 7 can also be provided between the lower surface 12 of the femoral neck 1 and the upper surface 23 of the handle body 2 to prevent new fibrous granulation tissue from entering the gap between the femoral neck 1 and the handle body 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com