Titanium-containing amorphous carbon high-hardness andwear resistant thin film

An amorphous carbon and amorphous carbon layer technology, applied in the field of materials, can solve problems such as material brittleness and film application limitations, and achieve the effects of improving wear resistance, improving mechanical properties, and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

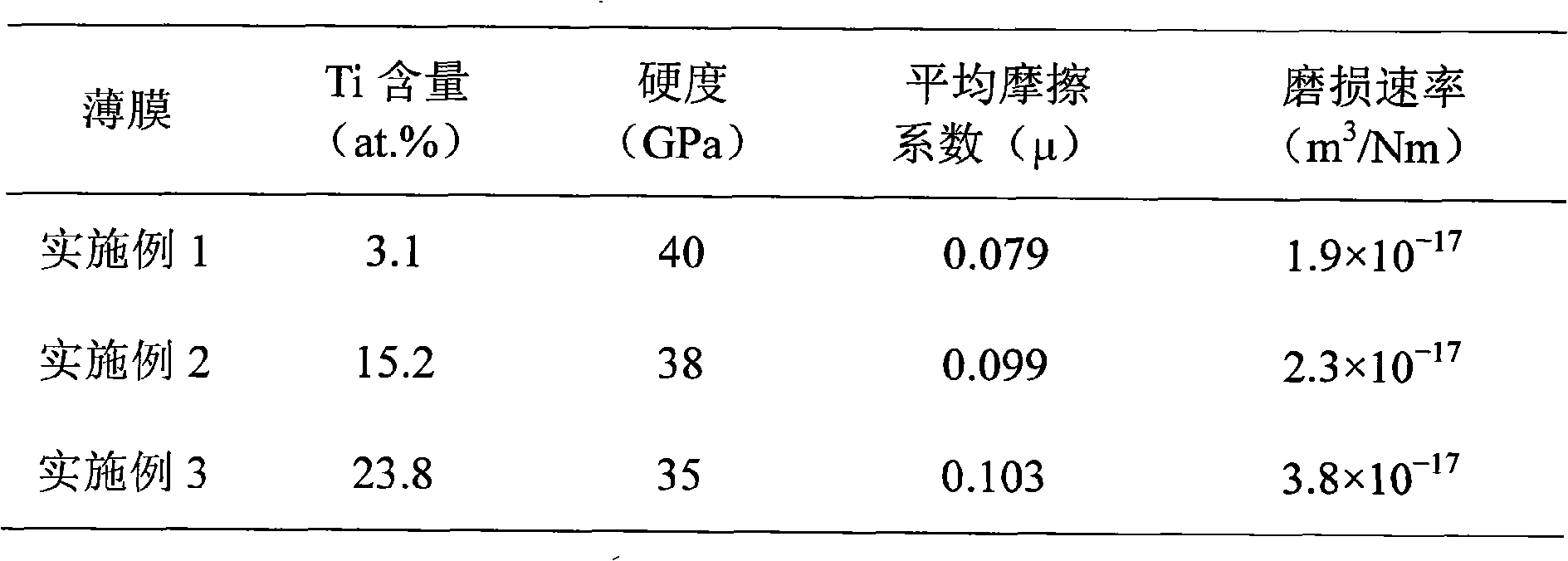

Embodiment 1

[0019] 1) The titanium-containing amorphous carbon high-hardness and wear-resistant film was prepared by unbalanced magnetron sputtering technology. Choose metal titanium and pure graphite with a purity of 99.8% as the target material, place pure graphite targets and metal titanium targets in four directions perpendicular to the horizontal and at 90 degrees to each other, the graphite targets and metal titanium targets are arranged alternately; the metal substrate is heat-treated High-speed steel or titanium alloy, the distance between the target and the substrate is 15cm, and the rotation speed of the substrate is 4rpm.

[0020] 2) Vacuum the reaction chamber to 4.5×10 -3 Pa, followed by argon, its flow rate is controlled at 25 sccm. The target is self-sputtered for 6 minutes to remove oxides and impurities on the surface. The substrate was cleaned for 30 minutes, and the bias voltage of the substrate was kept at 500V.

[0021] 3) Deposit a pure titanium bottom layer on th...

Embodiment 2

[0026] 1) The titanium-containing amorphous carbon high-hardness and wear-resistant film was prepared by unbalanced magnetron sputtering technology. Choose metal titanium and pure graphite with a purity of 99.8% as the target material, place pure graphite targets and metal titanium targets in four directions perpendicular to the horizontal and at 90 degrees to each other, the graphite targets and metal titanium targets are arranged alternately; the metal substrate is heat-treated High-speed steel or titanium alloy, the distance between the target and the substrate is 15cm, and the rotation speed of the substrate is 4rpm.

[0027] 2) Vacuum the reaction chamber to 4.5×10 -3 Pa, followed by argon, its flow rate is controlled at 25 sccm. The target is self-sputtered for 6 minutes to remove oxides and impurities on the surface. The substrate was cleaned for 30 minutes, and the bias voltage of the substrate was kept at 500V.

[0028] 3) Deposit a pure titanium bottom layer on th...

Embodiment 3

[0033] 1) 1) Using unbalanced magnetron sputtering technology to prepare titanium-containing amorphous carbon high-hardness and wear-resistant films. Choose metal titanium and pure graphite with a purity of 99.8% as the target material, place pure graphite targets and metal titanium targets in four directions perpendicular to the horizontal and at 90 degrees to each other, the graphite targets and metal titanium targets are arranged alternately; the metal substrate is heat-treated High-speed steel or titanium alloy, the distance between the target and the substrate is 15cm, and the rotation speed of the substrate is 4rpm.

[0034] 2) Vacuum the reaction chamber to 4.5×10 -3 Pa, followed by argon, its flow rate is controlled at 25 sccm. The target is self-sputtered for 6 minutes to remove oxides and impurities on the surface. The substrate was cleaned for 30 minutes, and the bias voltage of the substrate was kept at 500V.

[0035] 3) Deposit a pure titanium bottom layer on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com