Horizontal type bone grain steaming device

A bone grain, horizontal technology, applied in the field of horizontal bone grain steaming equipment, can solve the problems of long steaming time, high labor intensity and high temperature, and achieve the effect of good impurity removal effect, good degreasing effect and constant temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

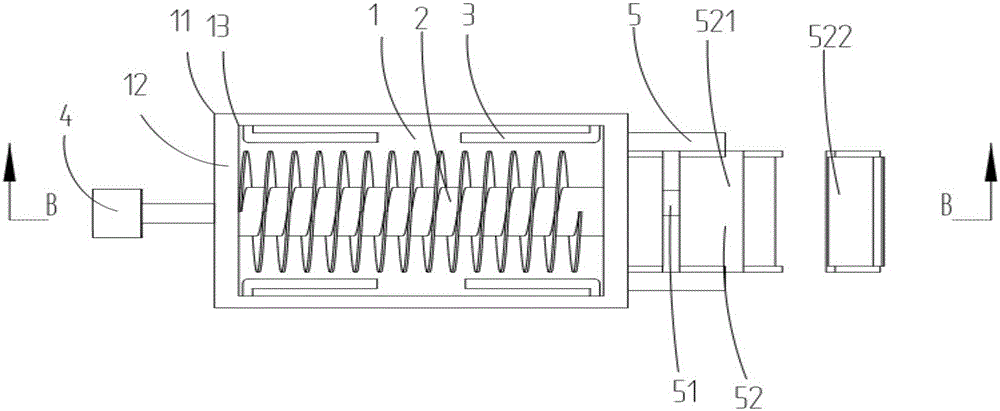

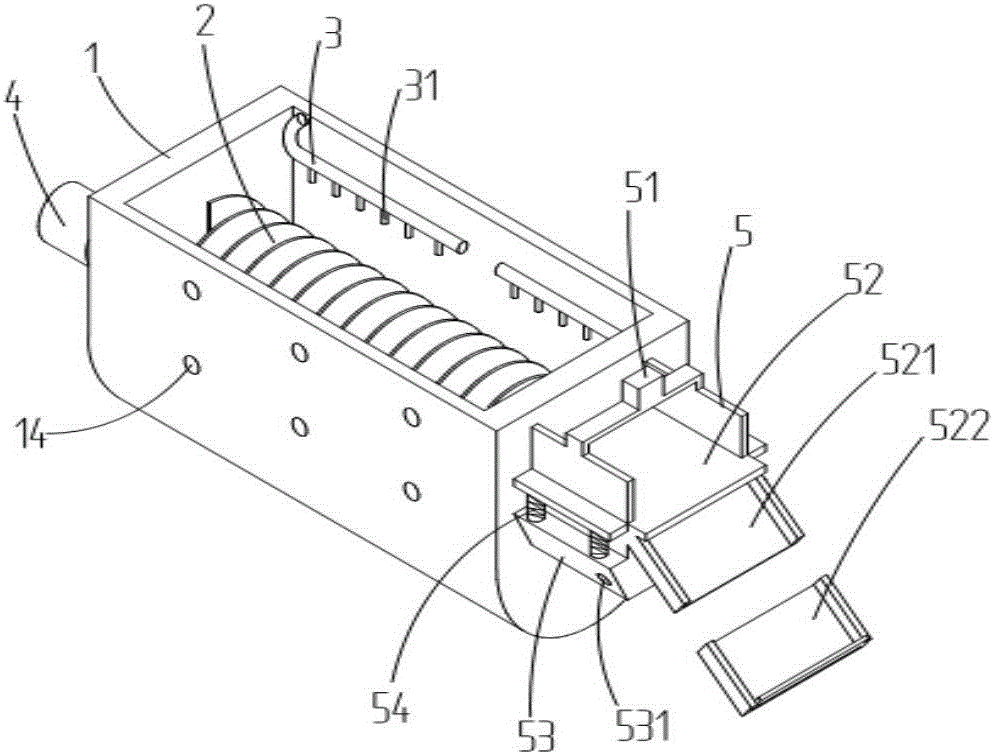

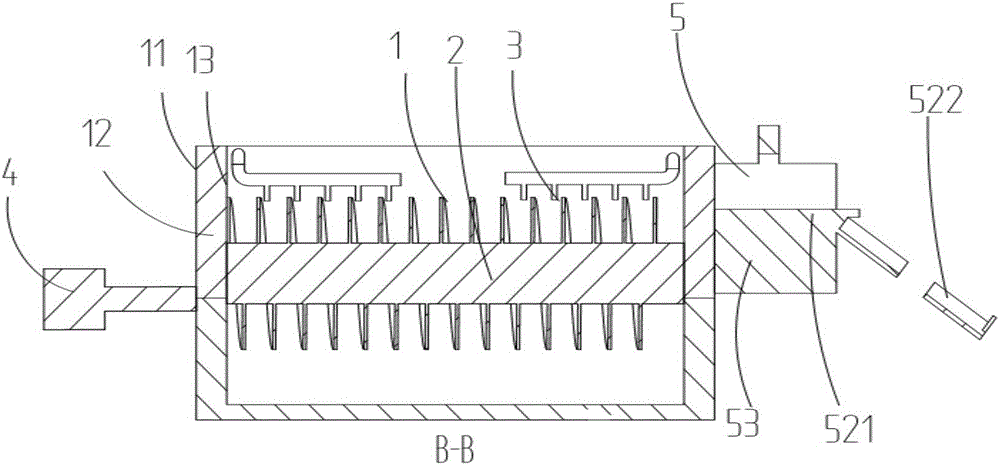

[0034] The horizontal bone grain steaming equipment of the present invention fills the interlayer 12 of the degreasing tank 1 with 85°-90° hot air and part of water through an external high-pressure heating air supply device before putting in the bone grains, and waits until the water is heated to boiling Feed the crushed bone grains into the degreasing tank 1 through the feeding port, turn on the motor 4 to make the screw feeding device 2 rotate and drive the bone grains to turn over and move. Playing the role of reinforcing ribs, part of the hot air in the interlayer 12 can be filled into the degreasing tank 1 through the air pipe 3 to make full use of it, and the tiny impurities floating on the inner surface of the degreasing tank and a small part of bone particles will pass through the gap at the discharge end of the degreasing tank 1 Flow into the flat delivery plate 521 of the impurity removal device 5, and open the vibrator to separate the bone grains from the impurities...

Embodiment 2

[0035] The horizontal bone grain steaming equipment of the present invention fills the interlayer 12 of the degreasing tank 1 with 85°-90° hot air and part of water through an external high-pressure heating air supply device before putting in the bone grains, and waits until the water is heated to boiling Feed the crushed bone particles into the degreasing tank 1 through the feed port, turn on the motor 4 to drive the screw feeding device 2 to rotate at a speed of 3r / min to drive the bone particles to turn and move, and the circular pipe 14 can prevent heat damage The expansion of the degreasing tank can also play the role of reinforcing ribs. Part of the hot air in the interlayer 12 can be filled into the degreasing tank 1 through the air pipe 3 to make full use of it. The gap at the discharge end of the tank 1 flows into the flat delivery plate 521 of the impurity removal device 5, and the vibrator is turned on to separate the bone grains from the impurities, and the liquid w...

Embodiment 3

[0037]The horizontal bone grain degreasing and steaming equipment of the present invention, the air inlet 15 is connected to the external heating air supply device, the pressure of the air supplied by the heating air supply device is higher than the pressure of the oil in the degreasing tank 1, and the air inlet 15 passes through the outer layer 13 is connected to the interlayer 12, and a circular air pipe 31 is installed on the air pipe 3, and the diameter of the circular air pipe 31 decreases from large to small along with the feed end of the degreasing tank 1 to the discharge end.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com