Forging die and die forging technology for brake disc hub of high speed train

A technology for high-speed trains and brake discs, applied in the field of forging, can solve the problems of low forming precision of forgings, difficult positioning of preforms, high equipment requirements, etc., and achieve high production efficiency, avoid difficult positioning, and high forming precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings, and the described embodiments are only a part of the embodiments of the present invention, not all of them.

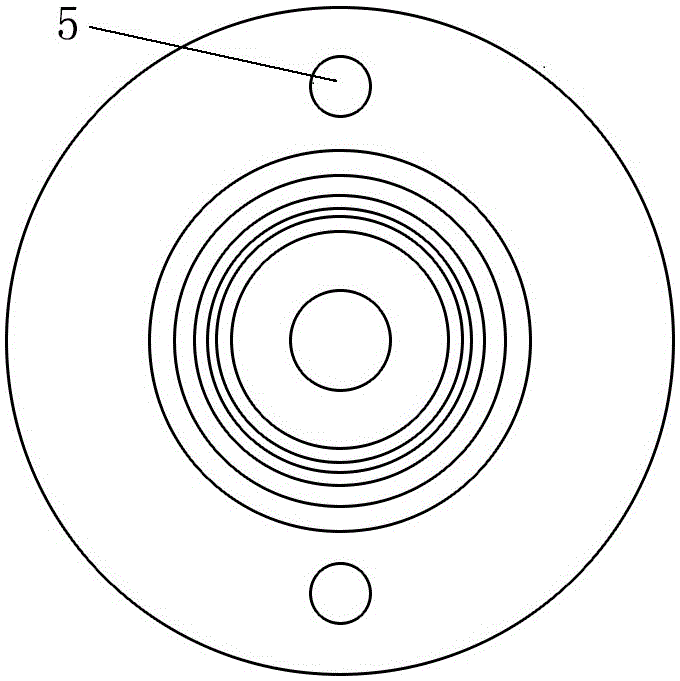

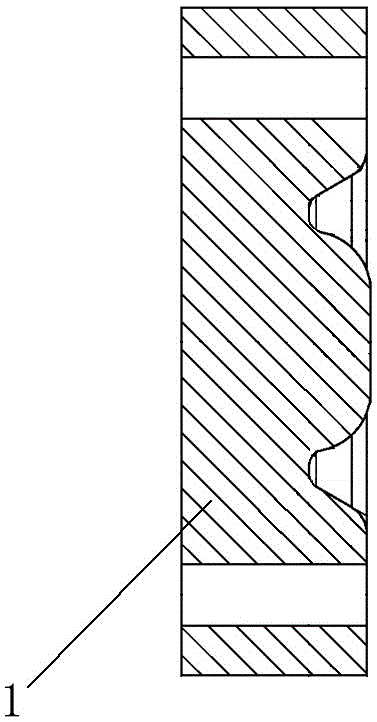

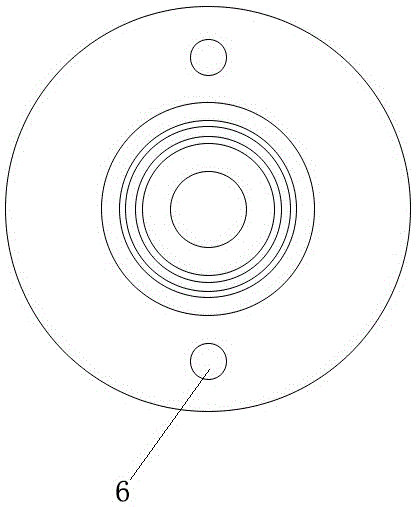

[0048] Such as Figure 1-4As shown, a high-speed train brake disc hub forging die includes pre-forging upper die (1), pre-forging lower die (2), final forging upper die (3), final forging lower die (4), pre-forging After the upper die (1) and the pre-forging lower die (2) are closed, the pre-forging die chamber is formed, and the final forging upper die (3) and the final forging lower die (4) are closed to form the final forging die chamber, and the pre-forging upper die (1 ) is provided with 2 upper guide through holes (5) with symmetrical positions, and the pre-forging lower die (2) is provided with 2 lower guide through holes (6) corresponding to the pre-forging upper die (1). After the mold (1) and the pre-forging lo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap