Material compounding device in belt conveying mechanism and method

A technology of belt conveying and compounding device, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of large left and right position deviation, affect the appearance of products, affect the yield of products, etc., and achieve effective conveying and effective material. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

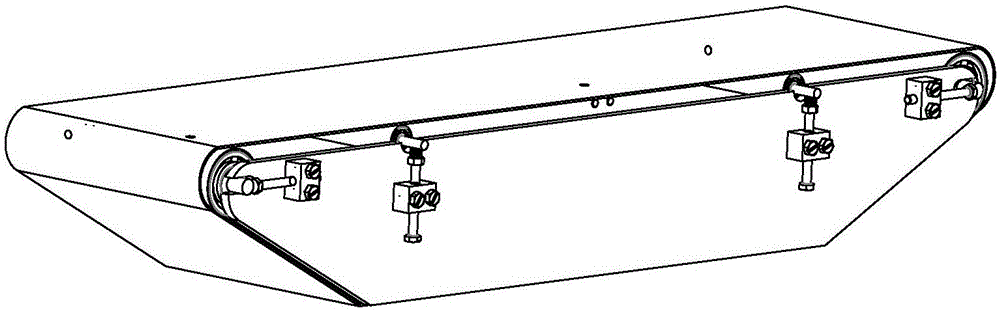

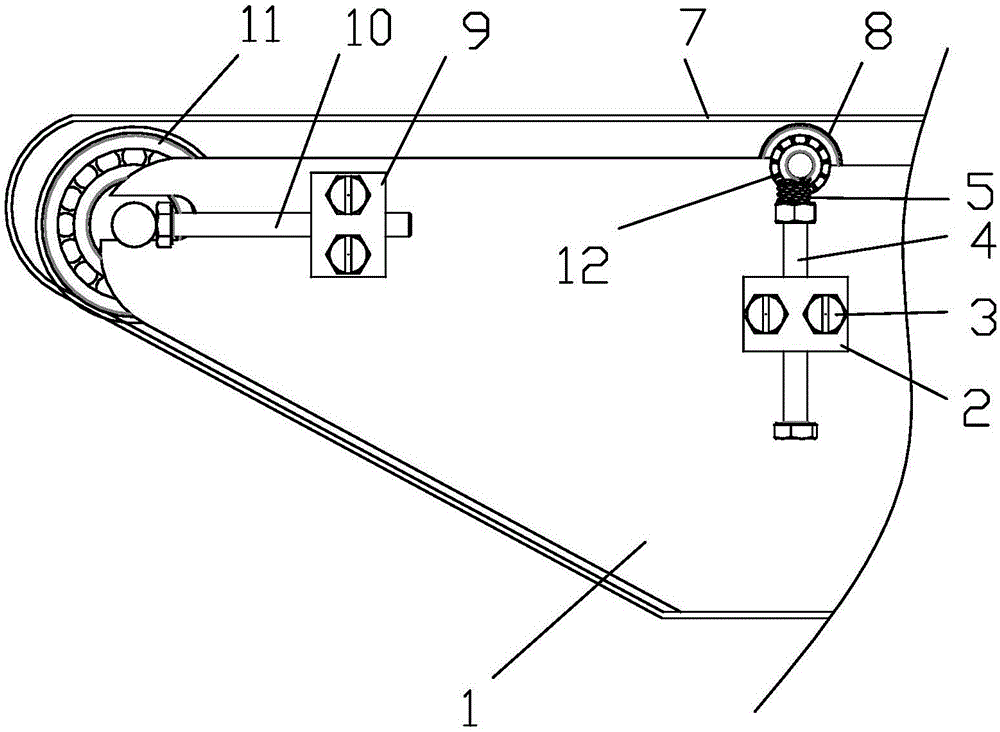

[0034] Embodiment 1: as Figure 1~6 , a material composite device and method in a belt conveying mechanism, said belt conveying mechanism comprising a side plate 1, two timing pulleys 11 and a belt 7 arranged on the side plate; at least one height Adjustment mechanism; the height adjustment mechanism is located between 2 timing pulleys;

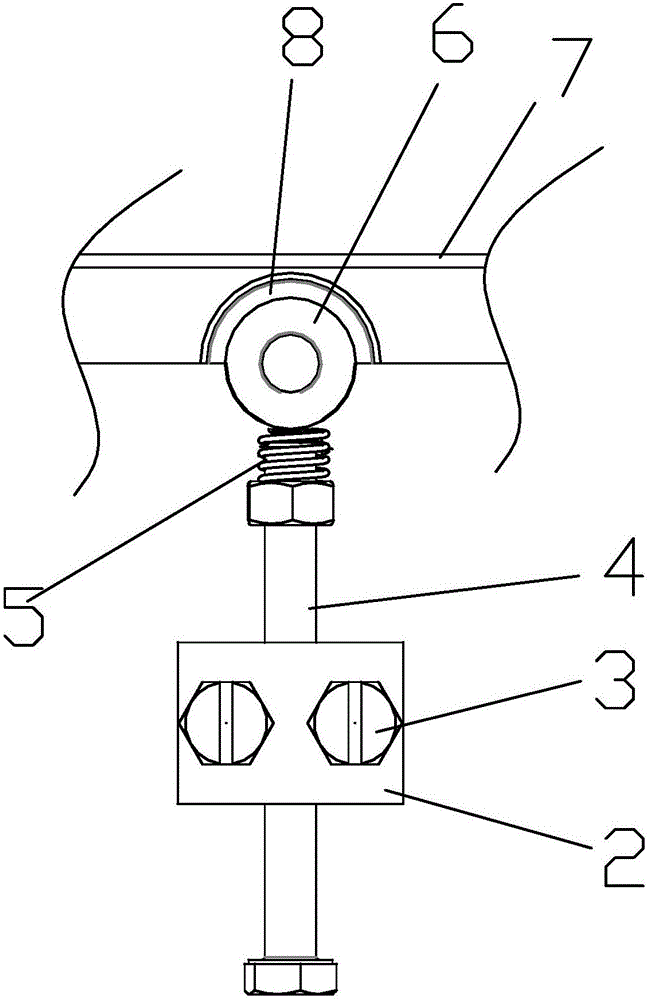

[0035] The height adjustment mechanism includes a first fixed base 2, a height adjustment screw 4 and an adjustment wheel 8;

[0036] The first fixed base is fixed on the side plate; the first fixed base is provided with a screw hole for inserting the height adjustment screw; the wheel shaft of the adjustment wheel is supported by the upper end of the height adjustment screw.

[0037] The height adjustment mechanism also includes a ring 6; the axle of the adjustment wheel is inserted in the ring, and the bottom of the ring is supported by the upper end of the height adjustment screw. The circular ring is used for inserting the wheel axle, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com