Active control system and method for flexible guide rail rope deflection

A technology of active control system and flexible guide rail, which is used in elevators, lifting equipment in mines, transportation and packaging, etc., can solve problems such as yaw suppression, and achieve the effect of eliminating collision damage, avoiding direct collision and low damage degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

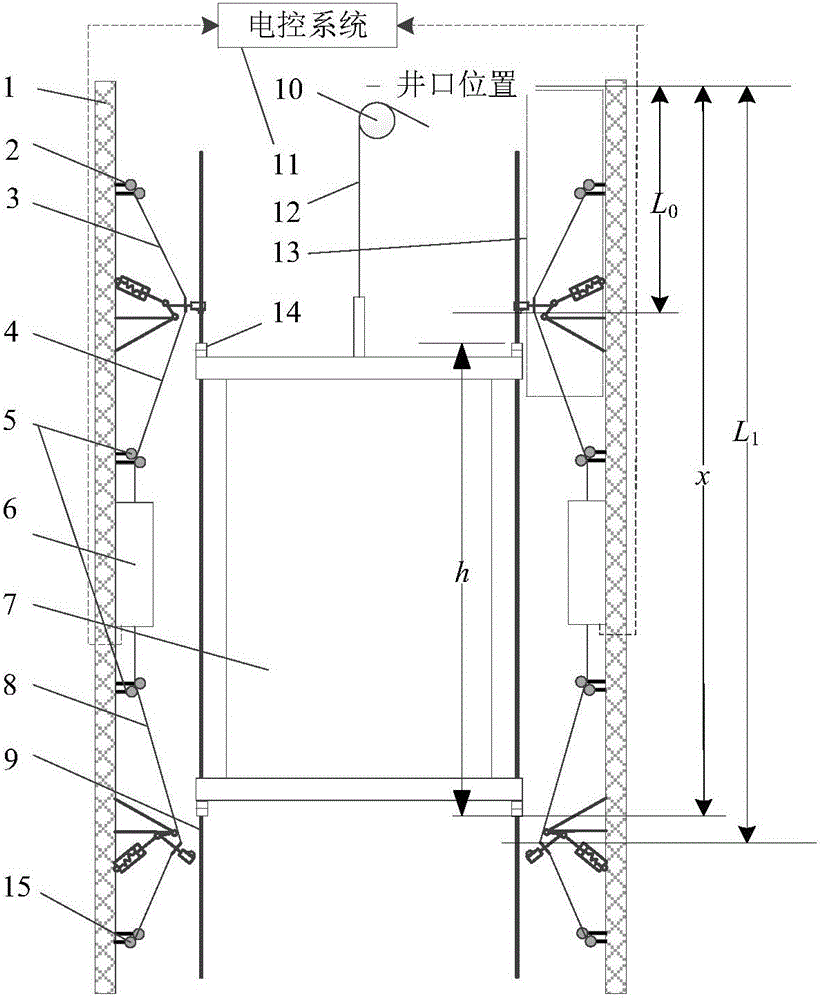

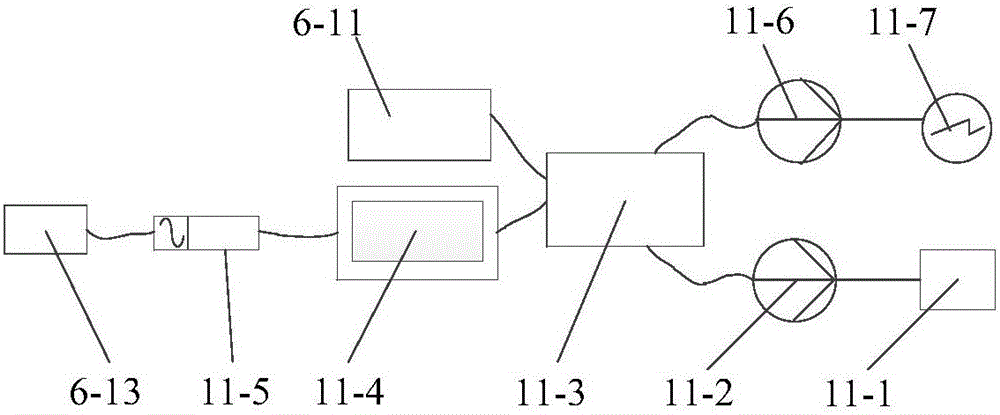

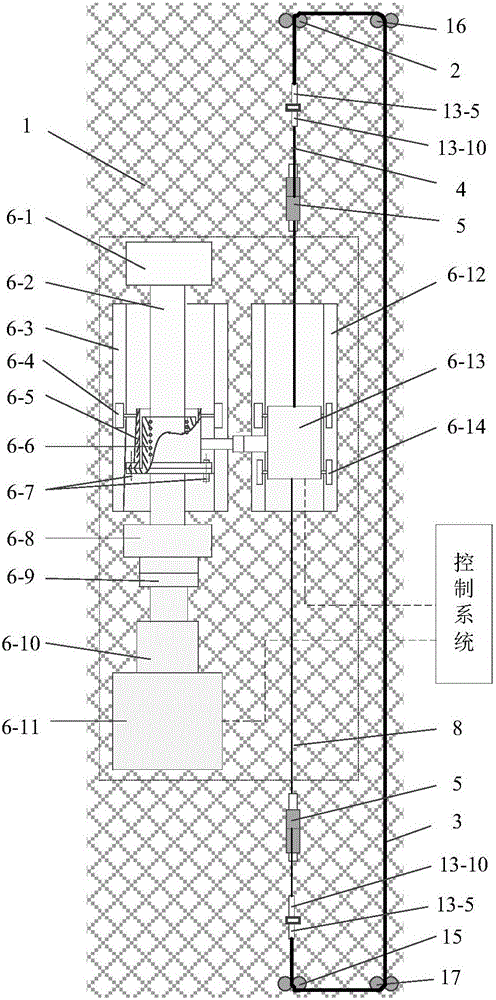

[0046] The active control system for the rope deflection of the flexible guide rail of the present invention includes a connecting rope guide pulley 2, a connecting rope 3, a four-bar mechanism stay rope 4, a stay rope guide pulley 5, an electromagnetic action system 6, a car 7, and a car guide rope 9 , driving wheel 10, electric control system 11, hoisting rope 12, four-bar mechanism 13 and car elastic bumper 14; The upper end of car 7 is connected with hoisting rope 12, and hoisting rope 12 passes driving wheel 10, in The upper end and the lower end of the car are respectively connected with two car guide ropes 9 symmetrically, and the car elastic touch block 14 is also connected with the junction of the car 7 and the car guide rope 9; the four-bar mechanism 13 has four, respectively with four A car guide rope 9 is connected, and the other end of the four-bar mechanism 13 is connected on the hoistway wall 1, and an electromagnetic action system 6 is respectively connected on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com