A kind of improved fermentation method of bacterial cellulose

A technology of bacterial cellulose and fermentation methods, applied in the direction of microbial-based methods, fermentation, biochemical equipment and methods, etc., can solve the problems of insufficient composite degree, small pore size, easy desorption, etc., to avoid fiber breakage, increase Disturbance degree, effect of water holding capacity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation of seed liquid among the present invention and parameter monitoring can refer to existing method, and wherein seed liquid can be made through the following steps:

[0021] The strains preserved at 4°C were kept at 30°C for 20 minutes, and a ring of strains was picked up with an inoculation loop and streaked on the solid plate medium, and the plate was cultured in a 30°C incubator for 36 hours. Pick 2-3 loops of the activated seeds with an inoculation loop, inoculate them into a 500mL Erlenmeyer flask containing 100mL of seed solution, and then put them into a shaker and culture them with reciprocating shaking at 120-160rpm for 48h.

[0022] Composition of solid medium (g / 100mL): glucose 2.0, sucrose 1.0, magnesium sulfate 0.04, citric acid 0.11, sodium dihydrogen phosphate 0.25, peptone 1.0, agar 1.8, yeast extract powder 0.1. pH=6.0. Sterilize at 121°C for 30min.

[0023] Seed solution composition (g / 100mL): glucose 2.0, ammonium sulfate 0.6, potassium...

Embodiment 1

[0033] The seed solution was inoculated into a 500mL Erlenmeyer flask containing 100mL fermentation broth, and the dynamic culture was carried out at 30°C for 72h at 160 rpm. After 20 hours of fermentation, different interference factors were added to interfere with the entire bacterial cellulose production and fermentation process. The amount of different interfering factors is: dithiothreitol 10mg, chloramphenicol 5mg, Tween-80 400mg, emulsifier OP-10 400mg, quartz sand 1500mg, nano-silica 300mg, the corresponding modified fermentation product bacteria The celluloses are BC-A, BC-B, BC-C, BC-D, BC-E and BC-F.

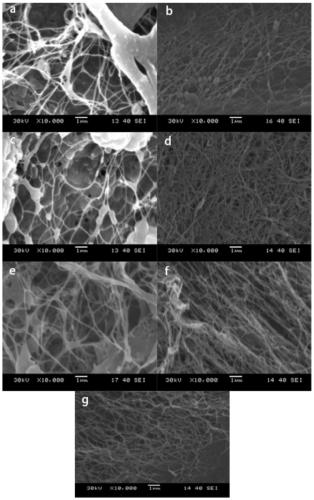

[0034] figure 1 It is the scanning electron micrograph of bacterial cellulose modified by adding interfering factors and without adding interfering factors, a is dithiothreitol, b is chloramphenicol, c is Tween-80, d is emulsifier OP- 10. e is quartz sand, f is nano silicon dioxide, and g is bacterial cellulose fermented without adding interfering factors. Depend o...

Embodiment 2

[0036]The seed solution was inoculated into a 500mL Erlenmeyer flask containing 100mL fermentation broth, and the dynamic culture was carried out at 30°C for 72h at 160 rpm. After 35 hours of fermentation, different interference factors were added to interfere with the entire bacterial cellulose production and fermentation process. The amounts of different interfering factors are: dithiothreitol 15mg, chloramphenicol 10mg, Tween-80 500mg, emulsifier OP-10 500mg, quartz sand 2000mg, nano silicon dioxide 400mg, the corresponding modified fermentation product bacteria The celluloses are BC-A, BC-B, BC-C, BC-D, BC-E and BC-F.

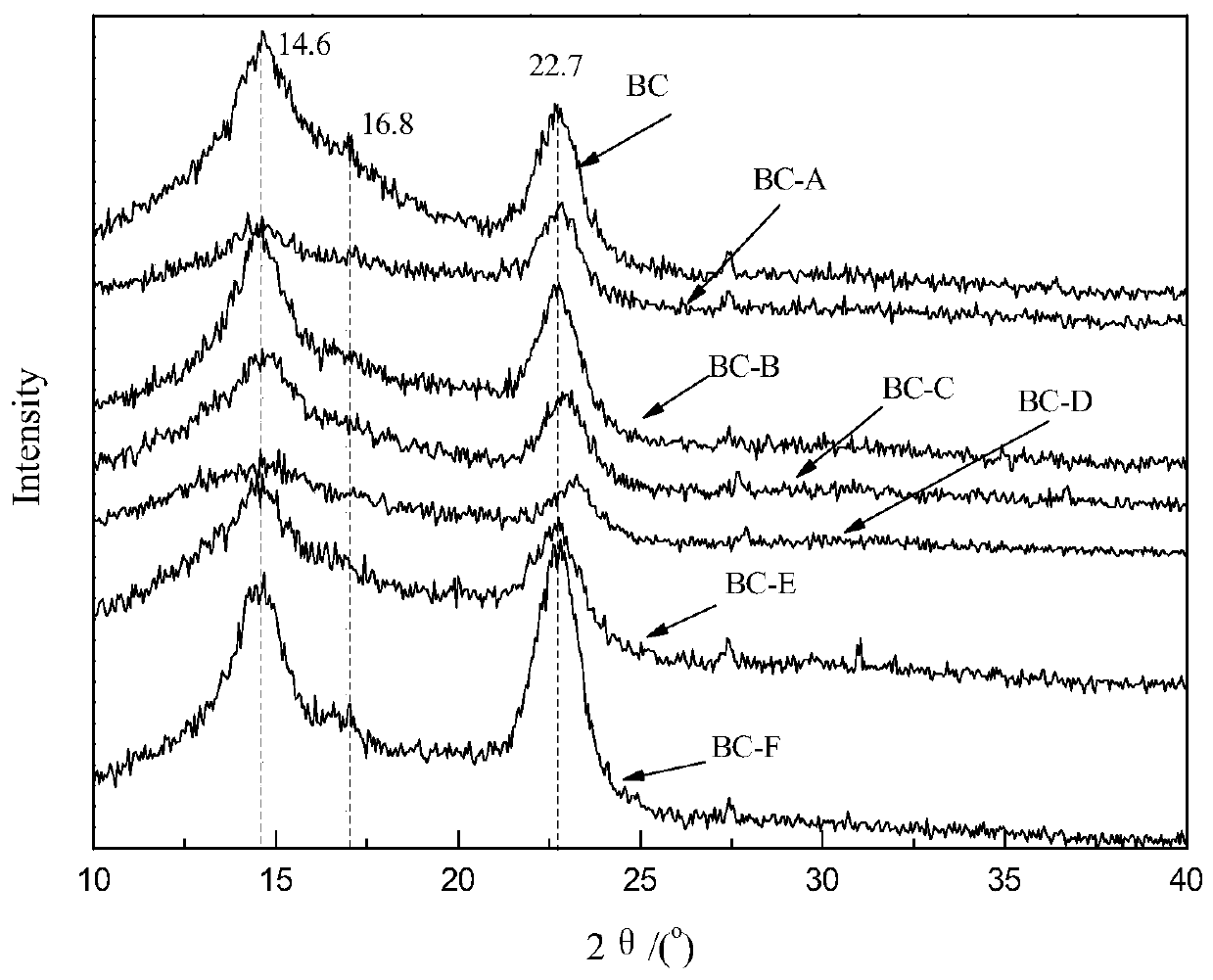

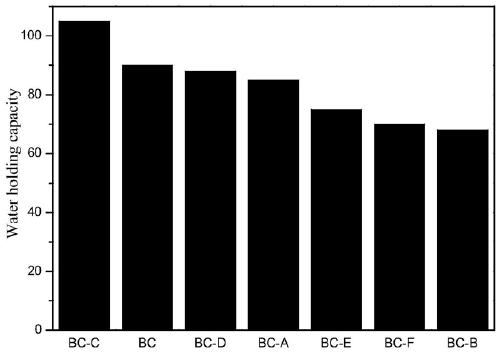

[0037] figure 2 It is the XRD pattern of the product bacterial cellulose modified by adding interfering factors and without adding interfering factors. pass figure 2 , calculate the crystallization index of cellulose interfered by different interference factors, the results are shown in Table 1. It can be seen from Table 1 that, except that the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com