Fiber felt manufacturing device

A preparation device and fiber felt technology, which is applied in the field of needleless batch fiber felt preparation devices, can solve the problems of low fiber production output, easy blockage of spinnerets, high starting voltage, etc., and achieve the effect of improving efficiency and fiber quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] By adopting the technical solution of this embodiment, a fiber mat with uniform fiber diameter can be prepared.

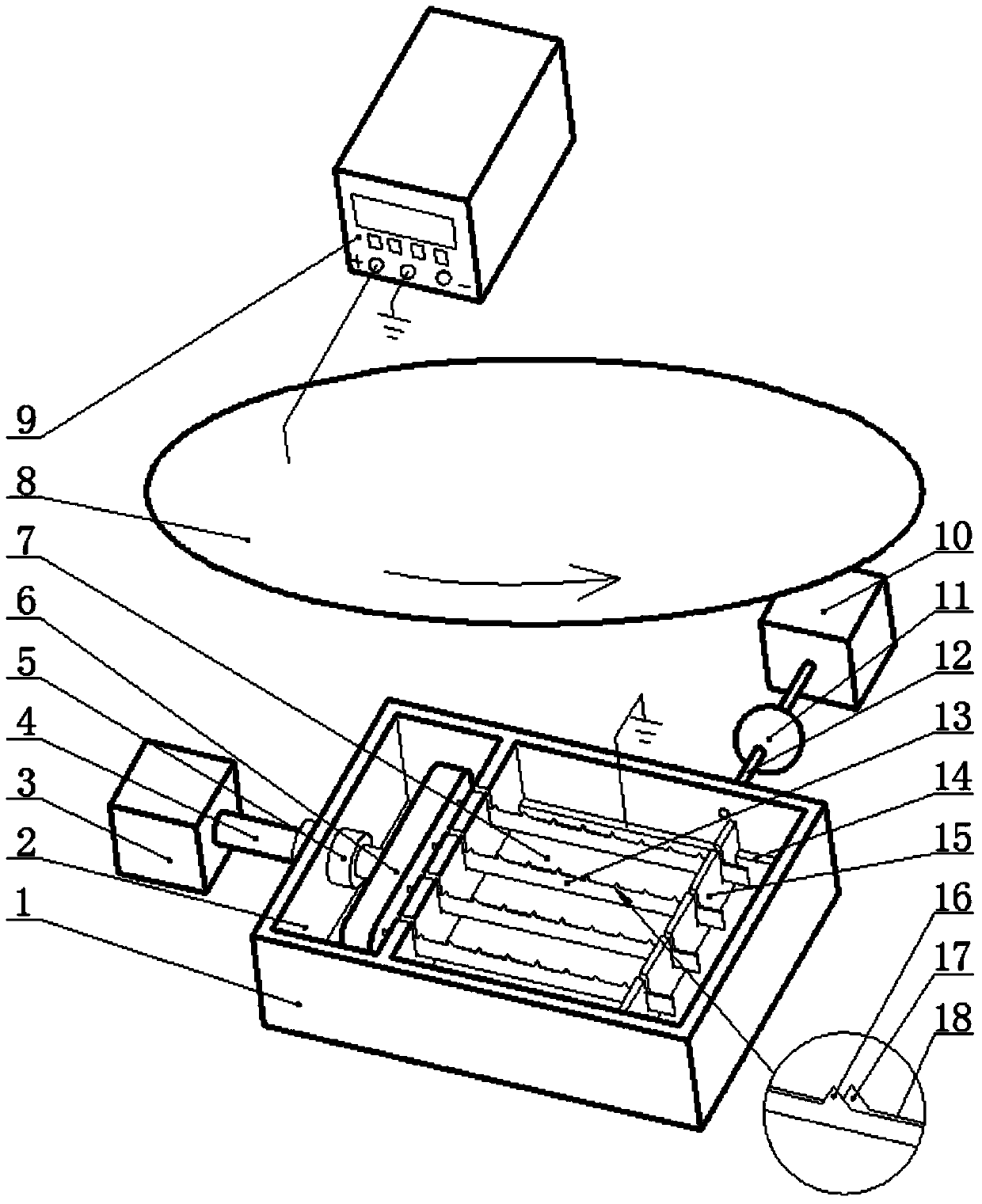

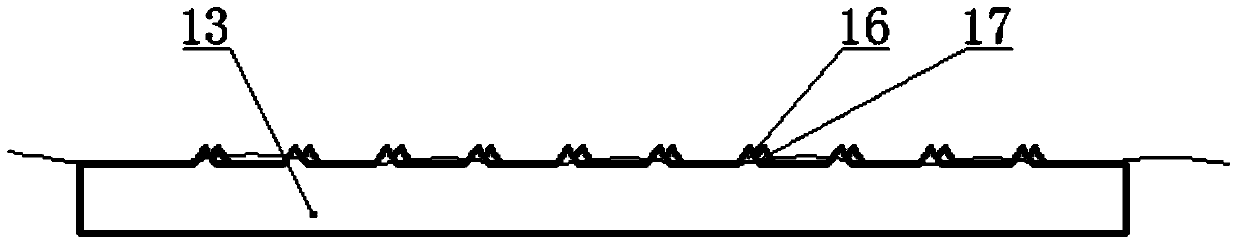

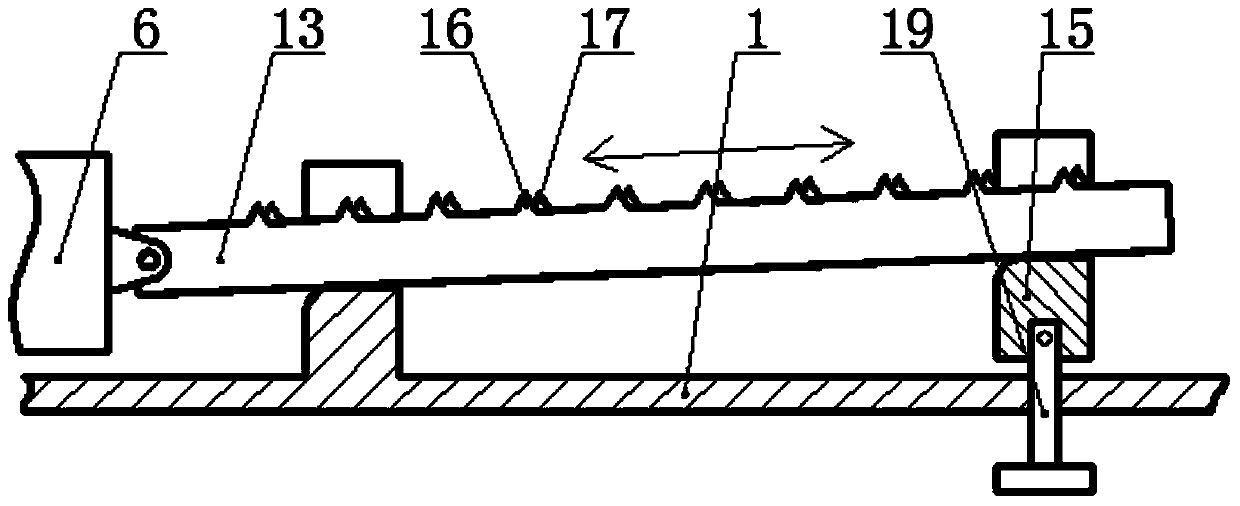

[0028] Such as figure 1 and 2 As shown, Embodiment 1 of the present invention is provided with a spinning box 1 , a vibration generating device 3 , a vibration transmission system, a liquid supply system, a collection device, a high voltage power supply 9 , an induction piece 13 and a fixing piece 18 . The spinning box 1 is divided into two tanks, a vibration conduction chamber 2 and a solution tank 7. The vibration conduction chamber 2 is used to prevent the vibration conduction block 6 from disturbing the solution during work; In the conduction chamber 2, the vibration conduction system is provided with a vibration output shaft 4, a connection seat 5, and a vibration conduction block 6; the liquid supply system is provided with a liquid storage tank 10 and a metering pump 11; the vibration output shaft 4 passes through the connection seat 5 Fixed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com