Operating device and method for spinning preparation machine

A technology of operating devices and machines, applied in textiles and papermaking, instruments, general control systems, etc., to achieve the effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

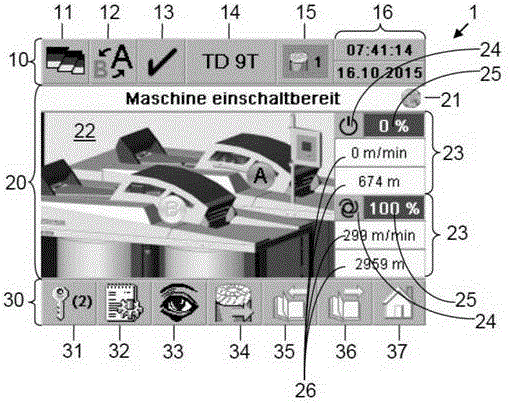

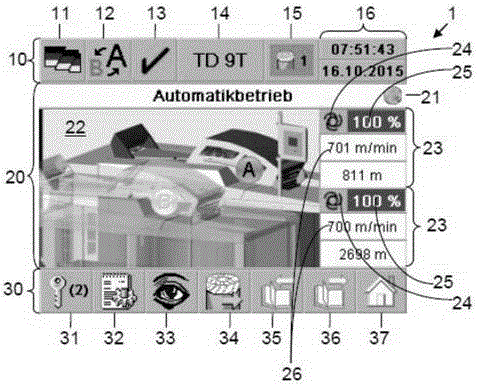

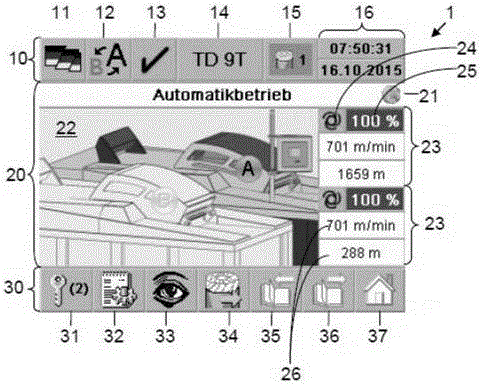

[0033] Figure 1a The operation with a touch screen and the first display state of the display device 1 are shown by way of example. Said screen 1 thus forms at least a part of the operator terminal. The screen 1 is divided into three parts and has three display segments 10 , 20 and 30 .

[0034] The display section 20 has a display section 22 which is here rectangular. This display section is used to display the spinning preparation machine coupled to the screen 1 . Two draw frames are shown by way of example as coupled spinning preparation machines.

[0035] The coupling generally takes place via a processor, which executes a corresponding program for operating the screen 1 . The processor is preferably coupled to the spinning mill processing machine via a control mechanism. The concept of "control mechanism" means that it is physically one or more control lines.

[0036] In the exemplary embodiment shown, the illustration of the draw frame is a three-dimensional struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com