Pedal anti-cracking road roller for building engineering

A technology for construction engineering and road rollers, applied in the directions of buildings, roads, roads, etc., can solve the problems of poor climbing, easy breakage of pedals, and easy dusting of road rollers, and achieves the effect of smooth road surface, labor-saving work, and enhanced climbing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

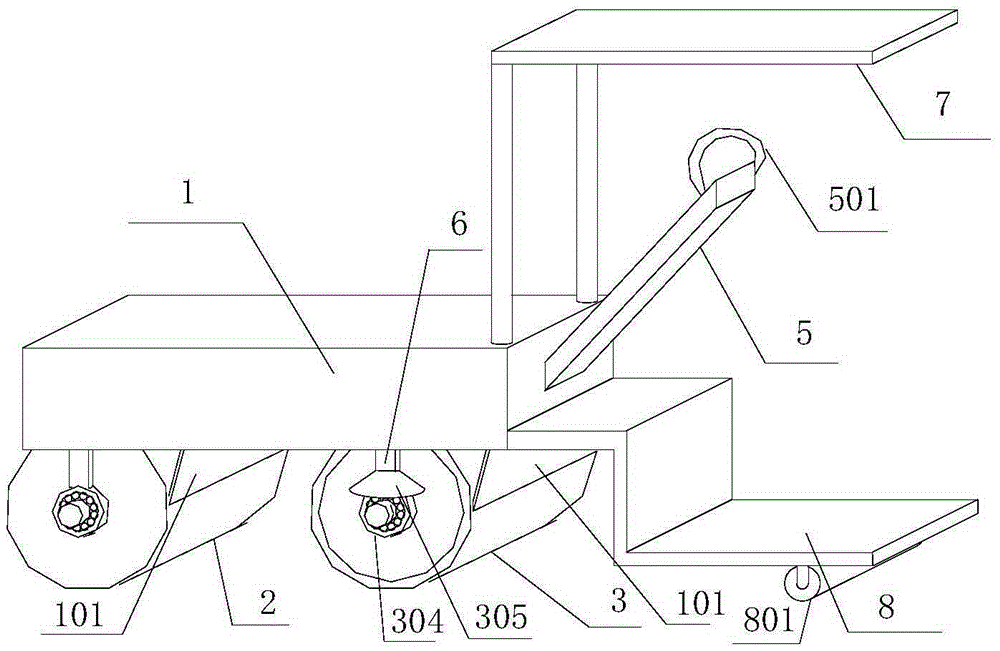

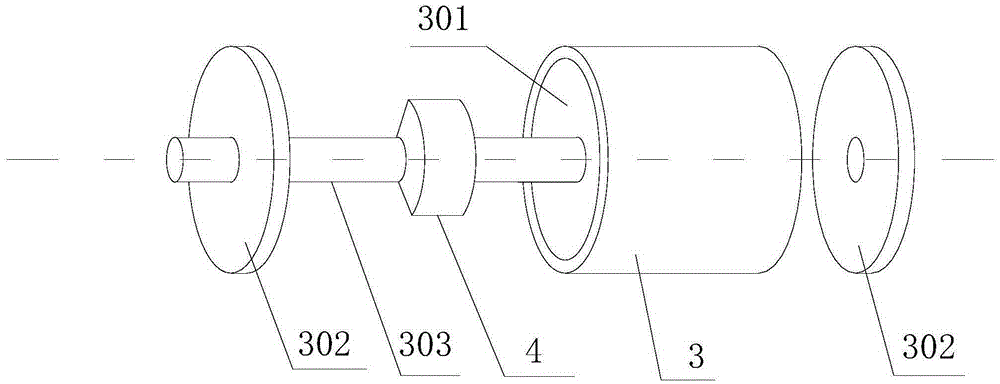

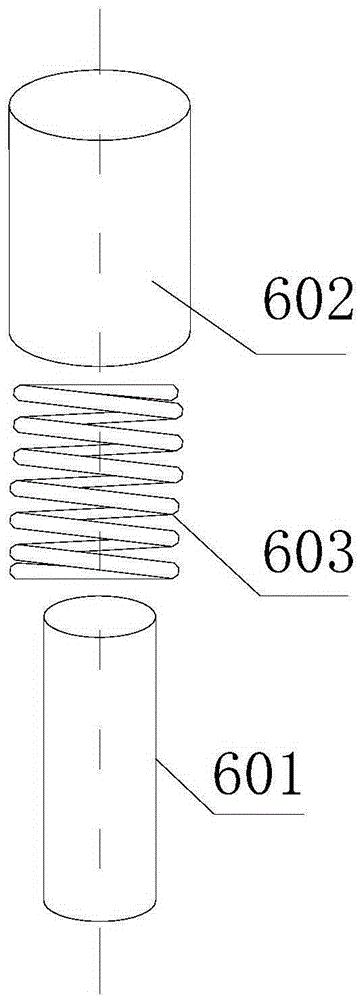

[0033] like Figure 1-Figure 4As shown, the pedal anti-crack road roller for construction engineering includes a fuselage 1, a front wheel 2 and a rear wheel 3 of the same size arranged under the fuselage 1, and the rear wheel 3 is a hollow cylinder. Both sides are respectively provided with a disc 302 fixed on the port 301 of the rear wheel 3, the crankshaft 303 of the rear wheel 3 passes through the center of the two discs 302, and an eccentric block is arranged inside the rear wheel 3 4. The eccentric block 4 is fixed on the crankshaft 303, and the two ends of the crankshaft 303 are rotatably connected to the fuselage 1. The rotating shaft of the front wheel 2 and the crankshaft 303 of the rear wheel 3 All are connected to the motor by a belt to drive rotation, and the two ends of the crankshaft 303 are provided with rollers 304, the rollers 304 cannot move in the extension direction of the crankshaft 303, and the rollers 304 are fixed on the fuselage 1 through the elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com