High-speed Inspired Clutch Based on Bevel Gear Internal Meshing

A bevel gear, internal meshing technology, applied in the field of high-speed inspired clutch structure, can solve problems such as flameout, inability to start the car, fuel consumption and friction lining time, etc., and achieve the effect of reducing control system failures, shortening mechanical response time, and increasing corresponding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

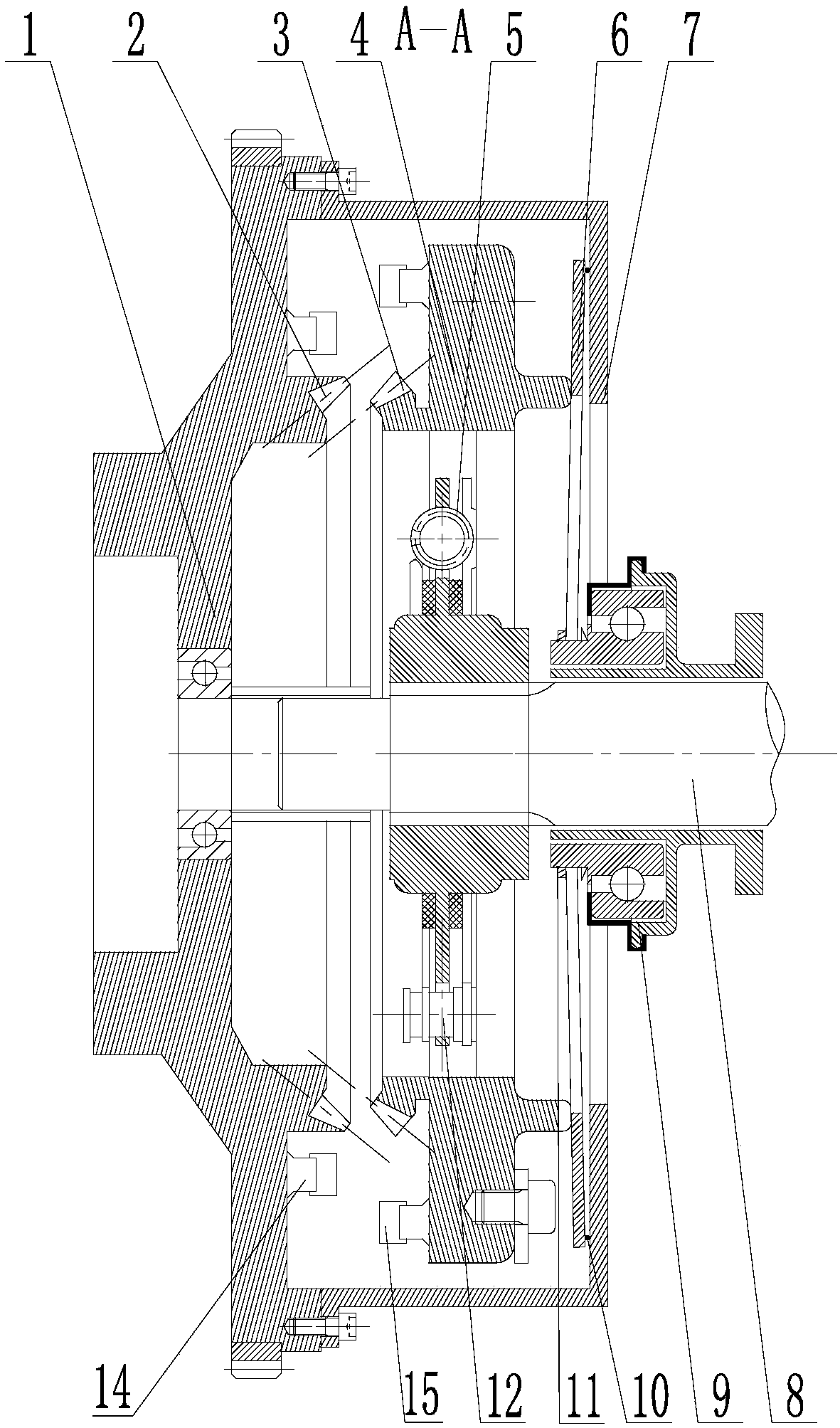

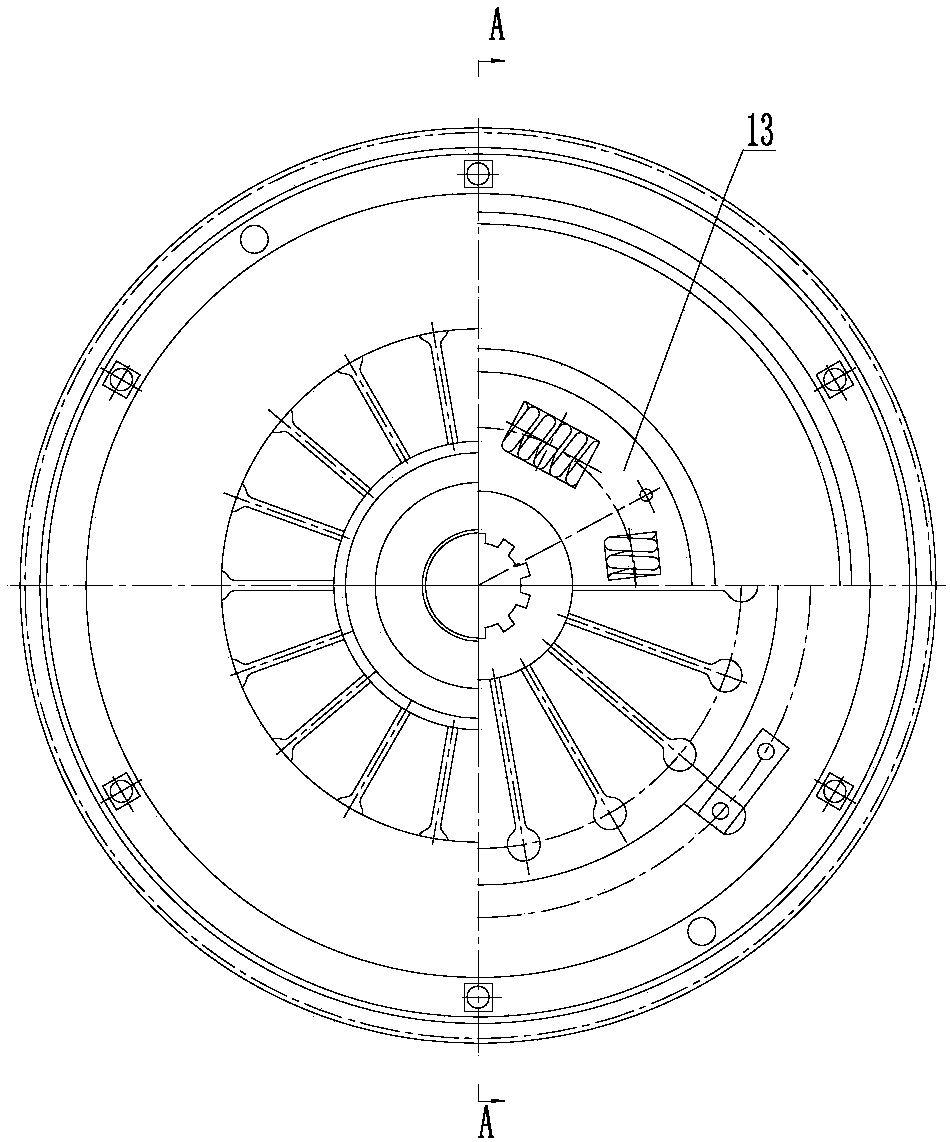

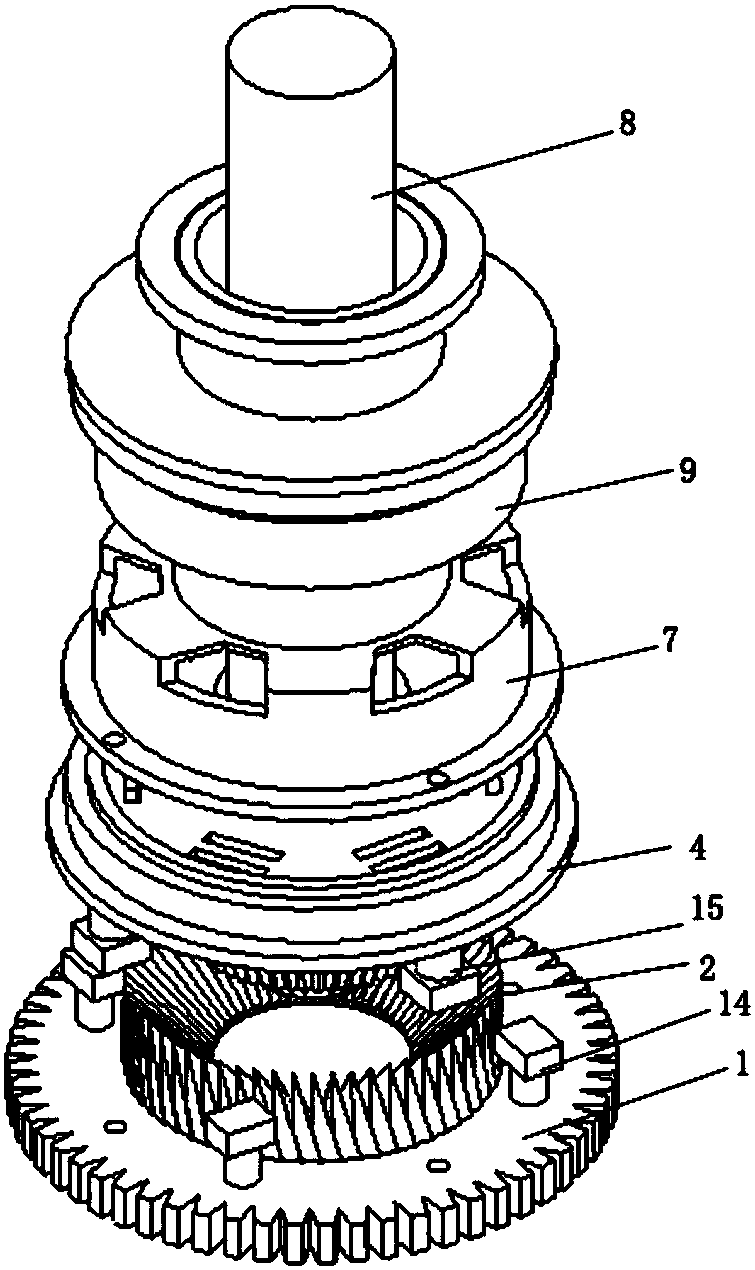

[0026] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] see Figure 1 to Figure 3 , the present invention is based on the high-speed inspired clutch of bevel gear internal meshing, including a flywheel 1, a shaft 8, and a pressure plate 4 and a release bearing 9 that are sequentially sleeved on the shaft 8 from left to right; wherein, the end face of the flywheel 1 is welded The internal bevel gear 2 moves synchronously with it; the internal bevel gear 2 can mesh with the bevel gear 3 under the closing action of the clutch; the bevel gear 3 is welded on the end surface of the pressure plate 4 to move synchronously; the shock absorber spring 5 is located The internal vibration damping part of the vibration damper 13; the internal hollow of the vibration damper 13 is sleeved on the shaft 8, and the vibration damper 13 is close to the bevel gear 3, which is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com