Parallel-serial capillary tube varying system inherent frequency vehicle shock absorber running method

A technology of natural frequency and operation method, which is applied to shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve the problems of small adjustable range and unadjustable natural frequency, and achieves low cost and simple and easy technical means. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

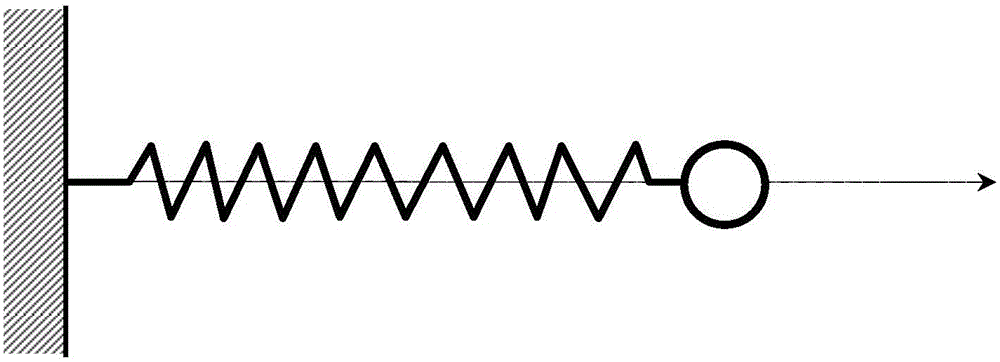

[0045] figure 1 , figure 2 See the background technology section for related content.

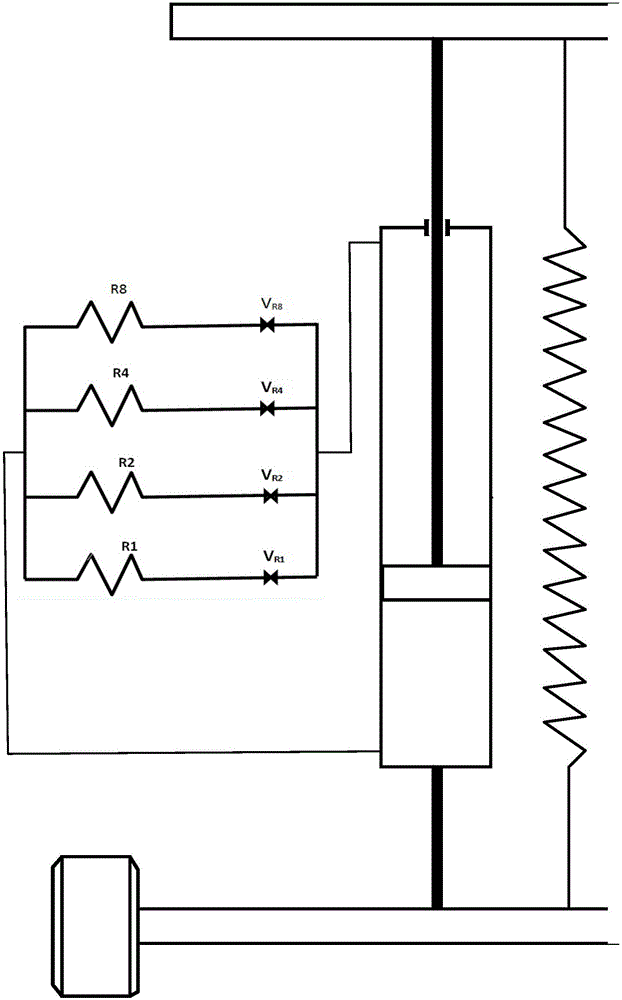

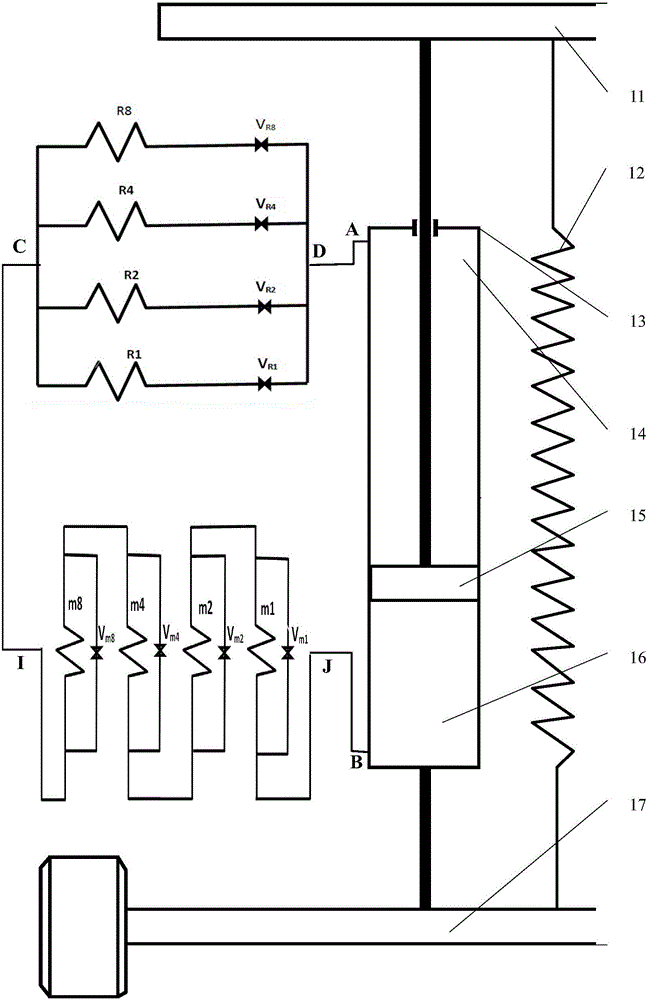

[0046] Such as image 3 shown. The resistance adjustment section includes four capillaries, which are R8, R4, R2, and R1; they are equal in length and connected in series with the solenoid valve V R8 , V R4 , V R2 , V R1 control its work. The ratio of the cross-sectional areas of these four capillaries is 8:4:2:1; their lengths are all L R .

[0047] The frequency modulation section includes four capillaries, which are m8, m4, m2, and m1; they have the same cross-sectional area and are connected in parallel with the solenoid valve V m8 , V m4 , V m2 , V m1 Control its work; the ratio of the lengths of these four capillaries is 8:4:2:1. In the present embodiment, the length L of the shortest capillary m1 among the four capillaries m1 Equal to the length L of the capillary in the resistance adjustment section R half of. The diameter d of these four capillaries m Equal to 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com