Vortex tube defrosting system for heat pump type passenger car air conditioner system

An air-conditioning system and vortex tube technology, applied in lighting and heating equipment, damage protection, refrigeration components, etc., can solve the problems of frequent defrosting and defrosting of the evaporator, the system cannot heat normally, and is not thorough, etc., to achieve the defrosting effect Obvious, slow frosting, good energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

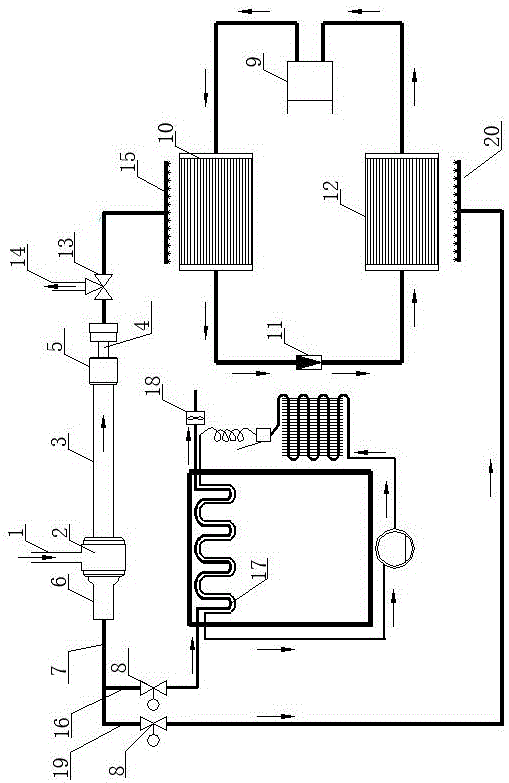

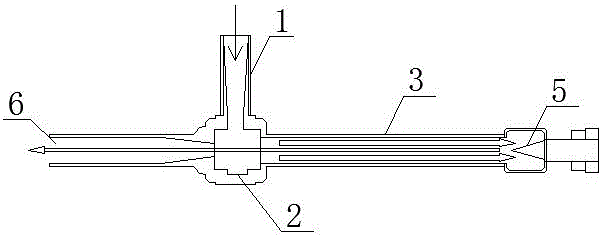

[0013] like Figure 1-2 As shown, a vortex tube defrosting system for heat pump air-conditioning systems of passenger cars includes a reducer 1, a vortex chamber 2, a compressor 9, a throttle valve 11, a defrosting assembly and a cooling assembly, and the reducer 1 and The vortex chamber 2 communicates, and the vortex chamber 2 communicates with the hot pipe 4 of the defrosting assembly through the vortex heat pipe 3, and a control valve 5 is arranged between the vortex heat pipe 3 and the heat pipe 4; the vortex chamber 2 communicates with the cooling assembly through the vortex cold pipe 6 The cold pipeline 7 communicates; and a solenoid valve 8 is provided on the cold pipeline 7; the inlet of the evaporator 10 of the defrosting assembly communicates with the outlet of the compressor 9; the outlet of the evaporator 10 is condensed with the cooling assembly through the throttle valve 11 The inlet of the condenser 12 is communicated, and the outlet of the condenser 12 is commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com